North West & North Wales

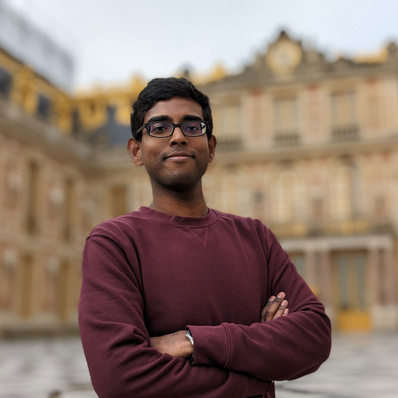

Rajinth Shanthar

Rajinth is a second-year PhD student from the Department of Materials, The University of Manchester, under the supervision of Dr Chamil Abeykoon, Dr Robert Prosser and Prof Prasad Potluri. His research is focused on simulating the flow of a liquid through a multiscale porous media, specifically the flow of polymeric resins across carbon and glass fibre fabrics.

He is trying to introduce the complex relationships observed in the physical world between the resin flow and parameters such as resin pressure, flow rate, temperature, and fabric properties into the numerical domain. Rajinth’s research spans a broad range of topics such as Computational Fluid Dynamics (CFD), polymer rheology, composite manufacturing, and process optimisation.

Optimised composite manufacturing using Resin Transfer Moulding

Composite materials have become a staple in modern engineering. For example, Fibre Reinforced Plastics (FRP) are widely used in industries such as aerospace and automotive thanks to their high strength-to-weight ratio. The reinforcement can be synthetic fibres such as carbon and glass, whereas the matrix is typically a thermosetting plastic. Resin Transfer Moulding (RTM) is a method of fabricating FRP parts, capable of achieving an excellent surface finish and high rates of production.

Here, the reinforcement fabric is placed within a rigid mould, injected with the liquid matrix material and finally heat cured. To optimise the RTM process and to ensure that the parts produced have high quality and minimum defects, Computational Fluid Dynamic (CFD) flow simulations can be used as a cost-effective approach. However, these CFD models need to sufficiently capture all the flow complexities associated with the RTM process to yield accurate and useful results.