Upcycling e-waste

Hackerspace community initiatives are tackling our planet’s ever-growing stockpiles of e-waste. Dr Parvez Alam FIMMM, Senior Lecturer in the School of Engineering at The University of Edinburgh, UK, explores some of the inspiring solutions.

Assuming continuity in the current growth rate of e-waste, we can expect to generate as much as 120Mt per year by 2050 worldwide. E-waste is produced at a rate of 50Mt each year globally. Great Britain alone is responsible for producing 1.6Mt of e-waste per annum, and, according to recent Basel Action Network reports, the UK remains the worst in Europe for illegally exporting toxic e-waste to developing countries. Around 10-20% of the UK’s e-waste is usually recycled, with the remaining 80% is sent to landfills or incinerators, damaging both the environment through harmful leachates and dioxins, and human health.

Materials in e-waste include metals such as iron and steels, copper and aluminium, as well as plastics such as high impact polystyrenes, acrylonitrile-butadiene-styrene co-polymers and polypropylenes. Precious metals such as silver, gold, palladium, iridium and rare earth metals exist in smaller fractions. Extraction of these is hazardous, requiring solutions such as hydrogen peroxide, hydrochloric and nitric acids, and sodium cyanides, which, in turn, necessitate highly specialised procedures for disposal.

Countries such as India, Nigeria and China have crude structures in place to extract valuable metals and components. The working environment is extremely hazardous, and the workers are typically paid little for their efforts. In several developing countries, the separation and deconstruction of such e-waste is a risk undertaken for the most part by children – a practice that is both ethically problematic and concerning.

Less hazardous alternatives to chemical extraction put forward include microbial processes. Both the bacterium C. biolaceum and the fungus A. niger could offer suitable alternatives for gold-plated e-waste, while the bacteria T. ferrooxidans and T. thiooxidans, as well as fungi A. niger and P. simplicissimum, have been shown to extract other metals such as lead, copper and aluminium.

Biological technologies such as these are of little benefit in the developing world, however, where people willingly expose themselves to hazardous chemicals to make economic ends meet. Moreover, many of the microorganism-based approaches are still at a low technology readiness level and, as such, the likelihood of mass upscaling and utility is, presumably, relatively low.

Hacktivities in Africa

An alternative to e-waste extraction – upcycling – has recently experienced a growth in impetus. This not only resolves many of the issues of human exposure to hazardous chemicals, but also adds economic value to e-waste, transforming it into higher-value products and machines. This is made possible through global and local networks of support, often taking the form of ‘hackerspace’ communities.

Born initially through small activities in Germany in the early 1990s, such as the Berlin-based C-Base, hackerspace movements are now found around the world. Most are in Europe and North America, however, many new projects have recently been launched in Asia, Africa and South America. Many of those in African countries are directly aimed at resurrecting e-waste to create entirely new products, with at best market potential and, at the very least, utility potential within the local community.

The Agbogbloshie Makerspace Platform (AMP) is an example of positive impact through e-waste upcycling. Located in one of the most polluted cities in the world, Accra in Ghana, AMP has direct access to the Agbogbloshie scrapyard, hosting a range of aeronautical, automotive, electronics and household waste. Rather than consenting to the idea that the scrapyard is a toxic e-waste dump, AMP employs the philosophy of upcycling and safe, urban, open-air manufacturing. The scrapyard is viewed as an ecosystem for machine hacking, where the materials and components are freely available from reclaimed e-waste sources.

The AMP provides disassembly templates for different types of e-waste, such as microwaves, televisions, air-conditioners, refrigerators, mobile phones and PCs, ensuring that local workers engaged in ‘hacktivities’ are able to deconstruct and rework the e-waste safely.

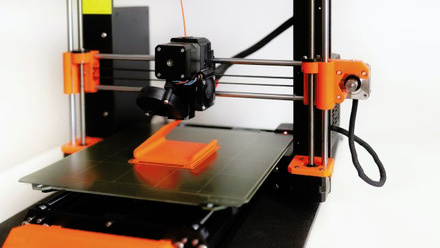

Another West African country, Togo, is home to WoeLab, which was the first African hackerspace set up in 2012. A relatively famous WoeLab success story is the W.Afate – a 3D-printer made almost entirely from e-waste. This said, WoeLab are big thinkers, having recently suggested in the NASA Space APP Challenge (hackathon) that e-waste can be upcycled and sent to Mars. Rather than sending e-waste to developing countries, WoeLab posits that it would be better to reconstruct e-waste into space technology for explorative purposes, at a fraction of the cost of higher-end technologies.

Reverse engineering in Asia

Asia produces only about one fifth of the e-waste per person compared with Europe. Yet, due to the significantly greater population size within the continent, Asia generates over 40% of the world’s e-waste (over 20Mt). Heightening levels correlate quite naturally with changes in accessibility to electronic products, with a more than 60% increase in e-waste produced across the entire continent within the last five years.

Online hackerspace listings reveal under 100 hackerspaces within the entire continent – low levels relative to its population size. Europe, in comparison, boasts over 520 listed hackerspaces, several of which are already engaged in upcycling e-waste. Given the scale of e-waste in Asia, it is somewhat surprising that only a handful of hackerspaces report a focus on upcycling, reconstructing, or managing e-waste. That said, there is growing impetus for improved management and upcycling of e-waste.

The SEA Makerthon, organised annually by the Southeast Asia Makerspace Network, is an aspirational example. In 2016, this event comprised hackerspace enthusiasts in 10 cities across South East Asia working through the summer to ‘design a world with zero waste’. Some of the inventions included – Internet of Things recycling kiosks for e-waste sorting and management, upcycled e-waste tracking devices, upcycled dehydration technology and e-waste reconstructed to turn food into high-quality fertiliser.

A dissimilar, yet equally creative, venture from 4R Recycling Pvt Ltd in Bangalore, India, formulated a pipeline to reconstruct e-waste into household showpieces. This is not upcycling per se, but reconstruction into creatively designed showpieces requires a different level of artistry and innovation, not usually seen in typical upcycling processes.

Recognising the need for additional upcycling activities in Asia, the most recent Global Challenges Research Fund project at The University of Edinburgh, UK, considers how e-waste in Nepal could be used to create robots and robotic parts.

In 2011, the Nepalese Government enacted the Solid Waste Management Act with aims to maintain a clean and healthy environment by minimising the adverse effects of solid waste on public health and the environment. E-waste is currently a major source of concern in the Nepalese capital Kathmandu, where it is dumped into landfills at a rate of around 18,000t per annum. There are, therefore, sizeable volumes of material available for recovery into marketable products.

The University of Edinburgh team is helping to develop reverse-engineering skills at Khwopa Engineering College, which is affiliated to Purbanchal University. This is providing new material with which the college will reinforce their taught course on Solid Waste Management. In parallel, the Edinburgh group is working on product development R&D at Green Nepal Recycling, a newly created SME with a ‘trash to treasure’ focus.

Nepal has a knowledge gap and, indeed, skills shortage around upcycling products from e-waste. Creating programmes for engineering students to fill these gaps is a means to instigate a new hackerspace community in Asia, focused on e-waste-derived products. In the longer term, this will strengthen local economies in Kathmandu, while concurrently decreasing the large volumes of landfill e-waste that Nepal has gathered over decades.

Although COVID-19 has put a pause on these activities in Nepal for the time being, the work will recommence, with the primary focus on upcycling e-waste to create robotic farm hands.

Waste or wonder?

How we manage our ever-increasing stockpiles of e-waste will depend to an extent on how we view them. As it stands, e-waste dumped into a landfill has no market value, but through innovation and creative design thinking, the same waste can be upcycled and sold.

To date, the extraction of precious metals is an economic driver that exposes both people and the environment in developing countries to hazardous toxic substances. Increasing the numbers of hackerspace communities, especially in those countries, might be a viable solution to the problems of e-waste management. Hackerspaces have the additional benefits of encouraging community development, skills development, economic development and creative thinking.