Ultra-black coatings - blocking out the light

Dr Michael Ford MIMMM at Haseltine Lake Kempner discusses patents and patent applications concerning carbon-based nanostructures that form ultra-black coatings.

University of Surrey spin-out company, Surrey Nanosystems, UK, made headlines in 2016 when it gave Turner Prize-wining artist Anish Kapoor exclusive rights to paint using a material branded as Vantablack and billed as the world’s 'blackest black'.

The ultra-black colour of the materials was achieved by increasing its optical absorbance and thus reducing the amount of light it reflected. The paint was initially developed as part of a project to improve the performance of electro-optical imaging systems in satellites. However, it has since found applications in optics and sensing technologies more broadly, as well as in art and design. For example, an exhibition of sculptural artworks using Vantablack was staged by Kapoor at the 2022 Venice Biennale. Some of the technology behind the range of coatings was described in various international patent applications, including WO2017/033027, WO2017/033031 and WO2019/073210.

WO2017/033027, which led to granted patents in China, Japan and the US, describes a method of coating a substrate with carbon nanostructures such as multi-walled carbon nanotubes to reduce surface reflectivity.

This method involves pre-heating the substrate and then spray-coating it with a suspension of the carbon nanostructures, with the temperature of the substrate controlled to cause rapid evaporation of the solvent in which the nanostructures are suspended.

The patent application also describes how the film density can be reduced and optical cavities can be created through plasma etching, or the addition of optical spacers to the nanostructure suspension prior to deposition. The experimental results included in the application provide evidence of coatings having total hemispherical reflectances as low as 0.20% at 0.7mm wavelengths.

According to WO2017/033031, which led to granted patents in Europe, China, Japan and the US, coatings having very low reflectivity can be formed from substantially vertically aligned carbon nanotubes grown on the surface of a substrate. However, at the time of filing, it was known that such coatings were prone to attack by atmospheric moisture, which could cause the optical properties to degrade.

It was also known that existing hydrophobic coatings, which could circumvent this problem, drastically reduce the material’s light-absorbing capabilities. In WO2017/033031, Surrey Nanosystems describes how such ultra-black materials can be improved using a chemical vapour deposition (CVD) methodology to deposit a fluorocarbon-based coating on top of the carbon nanotubes. This protects the carbon nanotubes from atmospheric moisture without a negative effect on the optical absorption. The application describes coatings with reflectivities down to 0.035%.

WO2019/073210, which led to granted patents in the UK, China and Japan, describes how similar low reflectivities can be achieved without the use of carbon nanotubes, which according to the patent application, can be relatively expensive to prepare and can be strong irritants to human eyes and mucus membranes. The coatings are formed by spray-coating substrates with suspensions of dyes and binders in such a way that a large number of pores are formed in the resultant structure. The pores act as optical traps to suppress light reflectance. The density of the coating is determined primarily by controlling the rate at which the solvent evaporates from the coating composition, whether in flight or rapidly after the composition contacts the substrate surface.

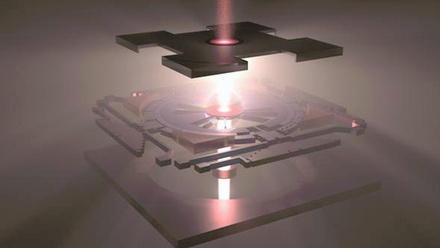

More recently, a group at the Massachusetts Institute of Technology (MIT), USA, has announced that they had developed a carbon-nanotube-based coating that they claim is 10 times blacker than any other ultra-black material. The new coating was described in an article in ACS Applied Materials & Interfaces and is the subject of international patent application WO2020/123974.

The application describes a process in which carbon nanotubes are grown on surface-activated aluminium sheets and foils through oxidative dehydrogenation CVD at low temperatures.

According to the application, this method avoids the formation of a native oxide layer between the substrate and the carbon nanotubes, and thus leads to faster electron transfer at interfaces between the nanostructures and the aluminium.

The resultant carbon nanotube/surface-activated aluminium structure also exhibits a very high specific surface area and a bimodal pore size distribution. The inventors suggest that, due to this combination of features, the material would make a suitable candidate hierarchical functional structure for energy storage applications such as batteries and supercapacitors.

However, the MIT-developed coating was also found to trap light extremely effectively and could therefore achieve a very low surface spectral reflectance, producing an ultra-black material. In fact, the inventors describe reflectances on the order of 10-5 over the UV, visible, near-infrared and mid-infrared wavelength ranges.

The process described in WO2020/123974 has already been applied by MIT artist-in-residence, Diemut Strebe, in a work of art called The Redemption of Vanity. In this work, the ultra-black material has been used to cloak a 16.78-carat natural yellow diamond, effectively causing it to disappear from sight.