Treating masonry

A patent for treating mineral substrates.

Mineral-based construction materials like concrete, stone and brick are naturally hydrophilic. Untreated masonry can absorb water from its environment, leading to deterioration in surface appearance, building dampness and even a breakdown in structural integrity.

Various surface treatments have been developed to provide mineral substrates with hydrophobicity. Typically, these are coatings or impregnations based on water-repellent alkyl silanes and siloxanes. However, there are problems associated with some existing treatments. For instance, those based on pure silanes and siloxanes are known to release volatile organic compounds (VOC), and they also suffer from low shelf-life and storage stability.

Coatings can be improved by adding amines, which act as catalysts for the condensation of alkyl silanes, or by use of n-octyltriethoxysilane (also known as triethoxy(octyl)silane), which has been found to provide long-lasting hydrophobicity. Unfortunately, both amines and n-octyltriethoxysilane are considered to be toxic and pose a danger to the environment. N-octyltriethoxysilane, in particular, has been identified as a significant threat to aquatic organisms and a pollutant of subterranean water systems.

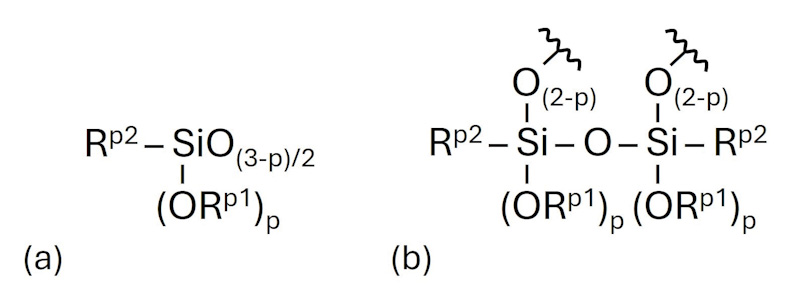

In January 2025, Evonik Operations GmbH was granted European patent EP4347734B1, entitled Environmentally friendly composition for treating mineral substrates. This claims protection for a surface treatment containing neither amines nor n-octyltriethoxysilane. Instead, the treatment is a dispersion comprising at least one butyl silane selected from the group, consisting of iso-butyltrialkoxysilane and n-butyltrialkoxysilane. It also comprises water and at least one silane-based compound made up of at least two building blocks, represented by the formula shown in figure (a) below – where Rp1 is selected from the group consisting of hydrogen, an alkyl group and an aryl group; and Rp2 is selected from the group consisting of a C3-C18-alkyl group and an alkenyl group. The p is selected from 0, 1 and 2.

According to the patent, such a dispersion enables improved hydrophobic effects without the use of toxic compounds. The “environmentally benign” dispersion is also storage-stable for at least 12 months at 20°C, which means that constant properties can be obtained over time when treating a mineral substrate surface with the formulation.

Iso-butyltriethoxysilane (also known as (2-methylpropyl)triethoxysilane) is a preferred butyl silane. It has been found to penetrate more efficiently into a mineral substrate and therefore enables an improved hydrophobic effect.

The patent provides an example (shown in figure (b) above) of a silane-based compound comprising at least two building blocks as claimed, bound to each other by a joint oxygen atom between the two silicon atoms of the individual building blocks. According to the inventors, when the Rp1 group in the silane-based compound is hydrogen (i.e. rather than an alkyl group or an aryl group), the amount of VOC generated on applying the treatment is reduced.

Experimental examples have been included in the patent to illustrate the effects of the claimed treatment. Two example dispersion compositions have been provided, each containing different relative amounts of iso-butyltriethoxysilane and n-propyltriethoxysilane oligomer as the butyl silane and silane-based compounds, respectively, combined with emulsifiers, a preservative, a pH adjuster and water.

Both compositions were found to produce oil-in-water emulsions that remained stable for more than 12 months at room temperature. When applied to concrete test specimens, the example compositions were found to achieve a reduction in water uptake (measured following storage of treated samples underwater for 24 hours), as compared to three different comparative examples prepared using combinations of octyltriethoxysilane/n-octyltriethoxysiloxane, octyltriethoxysilane/n-propyltriethoxysilane and propyltriethoxysilane/n-propyltriethoxysilane, respectively.

One of the example compositions – in accordance with the claims – also achieved the greatest penetration depth (measured by fracturing treated specimens and wetting the material with an aqueous solution of methylene blue).

The patent also claims protection for a method of preparing the dispersion, which involves – providing an aqueous phase comprising water; providing the at least one butyl silane and the at least one silane-based compound; mixing the aqueous phase and the at least one butyl silane and the at least one silane-based compound; and applying a first pressure stage and a second pressure stage on the resulting mixture in a high-pressure homogeniser.

The patent also claims a method for treating a substrate surface using the dispersion, as well as an article that comprises a layer obtained by treating a substrate with the dispersion. This is preferably a mineral substrate of concrete, limestone, sandstone, terracotta, marble, loam, cement, granite, sand, shale, artificial stone, plaster and/or clay.

The patent is available online.