Tile glaze bites the dust

Contaminants in the air are being captured and repurposed to make coloured glazes for ceramic tiles.

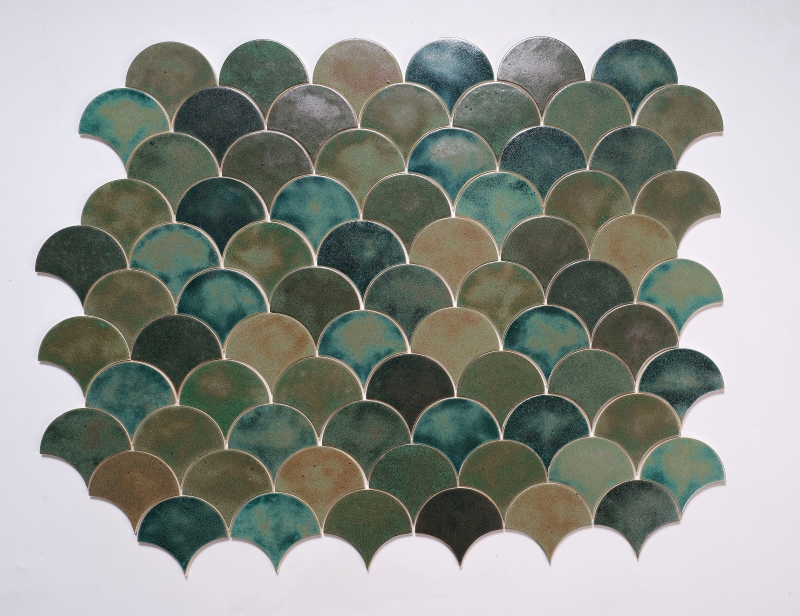

Christine Jetten works from her studio in Den Bosch, the Netherlands, designing glazes and textures in ceramics for buildings worldwide. She joined forces with ENS Clean Air Solutions from Cuijk and Dijkstra Friese Kleiwarenfabriek in Sneek, the Netherlands, on the Clean Air City Ceramics project.

Harmful particulate matter that is collected directly from the city air as well as foundries is supplied by ENS to Jetten as a fine dust. Each ingredient has a function in a glaze recipe that Jetten has honed. She started experimenting with fine dust out of curiosity and finds that it works.

The tiles themselves are made of up to 60% of the fine dust, with differences according to desired colour and glaze quality, Jetten says, 'I tested different kinds just for the visual quality and how my glaze recipes behave. Then I include the material and I made line blends.'

As this is in the experimental phase, greater quantities may prove possible. Although she says for the colour to be achieved, even as little as 1% is beneficial. The fine dust in her bronze glaze comes from a foundry.

The use of the fine dust in the glaze has a two-fold benefit. Firstly, Jetten can use a lower percentage of virgin materials in her product, while secondly, ENS can safely reuse the air pollutants in an economically advantageous way without having to put it into storage.

To harvest the fine dust, ENS deploys a filter-less technology that electrically charges the air at 7,500m3 per hour at 350W.

It can steer the particles to a collection point where they can be harvested and donated to Jetten.

The amount of fine dust that ENS harvests is from a metal foundry that produces 100kg of dust per annum. In addition to the ENS work, the first results of a collaboration between Benedetta Pompili and Studio Christine Jetten are also promising, whereby defused asbestos is processed into clay.

Jetten asserts that she is primarily a designer with an experimental ethos, so would like more scientific engagement in the project for the future. 'There are things I cannot test. I would love to do close work with someone who can test the product for a better understanding.'

Further testing is especially needed on tiles on the façade of buildings, as opposed to those used in the interiors.