Testing glass production using ammonia

A demonstration of glass production using ammonia as fuel has been performed by manufacturer AGC at its site in Yokohama Technical Center, Japan.

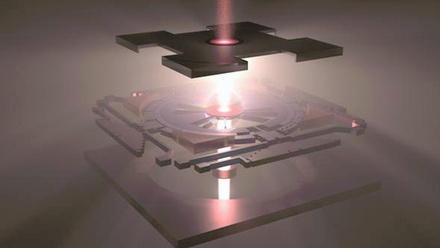

The test of ammonia combustion technology has been carried out using an ammonia-oxygen burner with low-NOx combustion technology, developed by Taiyo Nippon Sanso.

A pair of burners to prevent a rapid rise in flame temperature through multi-stage combustion were installed in the glass melting furnace used to produce architectural glass.

The effects on glass quality and furnace materials, as well as on control of flame temperature, furnace temperature and nitrogen oxide (NOx) emissions have been verified.

Shuhei Fujiyama of AGC says the advantages of this production are, 'ammonia can be produced from natural gas, renewable energy, etc. and does not emit CO2 when burned. In Japan, it can be produced and used at low cost by utilising existing infrastructure'.

He says, 'Since it was necessary to identify various tests at the lab level, it finally became possible to test the fuel in the actual furnace.'

Fujiyama shares, 'Flame temperature, radiation performance, etc. are lower than those of conventional fuels, which is a challenge for using ammonia as an alternative to fossil fuels.

'Ammonia has a lower flame temperature than methane or hydrogen…Heat transfer performance equivalent to that of a natural gas-air burner can be achieved by combining fuel ammonia and oxygen-enriched combustion'.

In this test, Fujiyama reports, 'The NOx concentration in the exhaust gas was maintained below the regulation value and successfully burned in the melting furnace.'

Regarding quality, 'there are no problems with lab-level testing. In order to further confirm the impact on quality, we need to conduct more scaled-up demonstration tests.

'During lab-level testing, we confirmed that there is [also] no furnace material impact from ammonia combustion'.

However, 'there are still technical issues to be resolved regarding the use of ammonia combustion technology in glass-melting kilns, but we are making steady progress toward practical application.'

The plan is to scale up demonstration tests under various conditions, as well as carry out basic testing and data collection using a 200kW-class burner, with scale-up to a 1MW-class burner. They plan to evaluate applicability to other types of glass-melting furnaces at other AGC sites.

Furthermore, the company will also consider expanding its application beyond glass to other materials, such as steel and aluminium, to widely help reduce greenhouse gas emissions at the AGC Yokohama Technical Center.

They aim to fully introduce ammonia combustion technology in 2026 or later, after determining the scope of its use.

The project – Technology Development for the Utilisation and Production of Ammonia as Fuel – is being undertaken as a commissioned project by the New Energy and Industrial Technology Development Organization.