Smart sutures that detect inflammation and deliver medication

Engineers at the Massachusetts Institute of Technology (MIT), USA, have designed ‘smart sutures’ from pig tissue that they claim can deliver drugs or sense inflammation. The invention could help patients heal after bowel resection or from other surgeries.

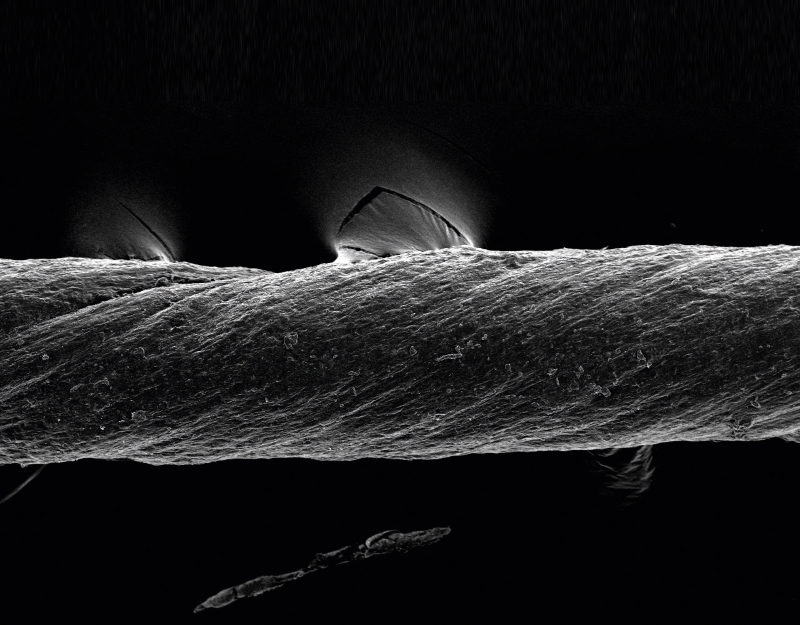

‘Catgut’ sutures – first used by ancient Romans – are derived from purified collagen from cows, sheep or goats and form strong knots that naturally dissolve in around 90 days. While synthetic absorbable sutures are available, catgut sutures are still used in surgeries today.

Co-lead author and former MIT Postdoctoral Researcher Jung Seung Lee says that they chose pig tissue as they wanted to ensure the tissue was a sufficiently long, decelluralised matrix, which can enhance tissue regeneration with minimal immunogenicity. They also found that 'the newly fabricated sutures showed the lowest immunomodulation compared to commercially available sutures including catgut ones'.

The MIT sutures are coated with hydrogels so that sensors, drugs or even cells that release therapeutic molecules can be embedded.

The team believes that tough and absorbable tissue-derived sutures that can act as sensors or deliver drugs could be especially helpful for those suffering from Crohn’s disease who require part-intestinal removal. This is because the sutures can detect inflammation and monitor the post-operation seal while holding tissue.

The team has decellularised the pig tissue to reduce the chances of inducing inflammation, leaving a cell-free material called ‘De-gut’ – it contains structural proteins such as collagen, and other biomolecules in the extracellular matrix that surrounds the cells.

To clean and remove the cell components from the tissues, a non-ionic detergent called triton X-100 was used before penicillin-streptomycin and ethylene oxide disinfected and sterilised them.

After dehydrating the tissue and twisting it into strands, the researchers have found that the tensile strength is comparable to commercially available catgut sutures.

Lee reports that they cultured the sutures with macrophages, a representative immune cell in our body, and the De-gut sutures induced fewer immune response-related signals compared to those cultured with catgut.

Next, they coated the sutures with a hydrogel layer, in which they can embed drug molecules or living cells, or microparticles to sense inflammation.

The researchers have designed microparticles coated with peptides that are released when inflammation-associated enzymes called MMP are detected in the tissue – these can be detected with a urine test. The drugs are released by diffusion and slow degradation of the polymer delivery system, which can be accelerated under inflammation.

The hydrogel coating is reportedly able to carry drugs for inflammatory bowel disease, including the steroid dexamethasone and the monoclonal antibody adalimumab. These are carried by microparticles from US Food and Drug Administration-approved polymers, such as polylactic acid and poly(lactic-co-glycolic acid), are used to control the drug’s release rate. The team says this could be adapted to deliver other drugs such as antibiotics or for chemotherapy.

The sustained release of drugs has been observed for up to two weeks – Lee says they expect the duration to be adjustable.

The team also believes the smart sutures could deliver therapeutic cells like stem cells. The sutures have been embedded with stem cells that express a fluorescent marker, finding that the cells are viable for at least seven days after being implanted in mice. The cells are able to produce vascular endothelial growth factor that stimulates blood cell growth.

Lee says that the De-gut suture can be degraded by enzymes in the body, which the hydrogel slows down but does not prevent.

The engineers are now working on testing each possible application and scaling up the manufacturing process.