Shrink film made from waste maritime plastic

Recycled plastic from maritime waste has been manufactured into shrink film

Made from discarded items such as fishing gear and ropes, the film can be used for food and beverage outer packaging say the makers.

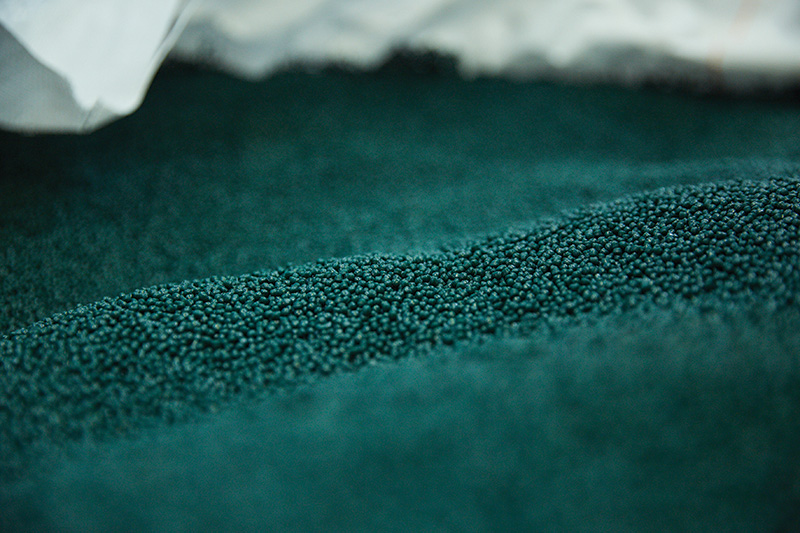

UK-based packaging consultancy and manufacturer Duo and Danish plastics recycler Plastix have partnered to launch the new shrink film, which is manufactured using recycled plastic pellets Oceanix HDPE (high-density polyethylene).

The recycled plastic, which is made from 98% maritime waste, is manufactured using advanced mechanical production technology and involves four main steps, says the Danish partner.

First, the fishing gear and ropes undergo an intense process of waste fractioning and homogenisation to reduce it down to tiny uniformed fibres.

Next, Plastix employs metal detection and cutting technology to separate any metals from the waste material, so that the feedstock used meets the environmental and quality standards required.

The thermoplastic is then washed, separated and dried before it is put through a plastic extrusion process.

Plastix says that it reviews and analyses its waste fibres at a chemical level and thoroughly monitors all recycling steps in accordance with ISO 9001, the international standard for quality management systems, and ISO 14001, the international equivalent for environmental management systems.

Once the shrink film is produced, Duo undertakes a number of tests to assess the material’s mechanical and physical properties, such as density, dart drop tensile and elongation.

The packaging consultancy says it has also trialled various material blends using different percentages of Oceanix HDPE to ensure that it could perform in the fast-moving consumer goods market.

Plastix has conducted a peer-reviewed Life Cycle Assessment (LCA) of Oceanix HDPE using the ISO 14040 and 14044 frameworks for environmental management lifecycle assessments.

This LCA report, say the developers, documents that the recycled plastic provides up to 94% CO₂e savings when compared with virgin plastics.

Hans Axel Kristensen, Chief Executive at Plastix, asserts, the study 'highlights that Oceanix HDPE is 11 times more climate efficient on freshwater use, five times more on ocean acidification and 43 times more on fossil resource use'.

The partners explain that original equipment manufacturers have, until recently, mainly focused on the physical, mechanical and thermal properties and metrics of the products they make.

However, more recently sustainability measures, together with compliance properties, Scope 3 data, traceability and verified claims, have gained greater prominence.

The Danish partner asserts Plastix is driven by producing transparent and verified green data and documentation in compliance with the 'Green Claims Directive to help stamp out concerns over green washing messaging'.

According to Duo, it is the first Plastix partner to use Oceanix HDPE to manufacture a flexible packaging product that can be recycled at the end of its use, while reducing reliance on virgin plastic and helping to minimise waste fishing gear pollution.

Manchester-based Duo adds the shrink film is visually arresting. 'The material is naturally green in colour giving brand owners a point of difference for their product, a real standout look on the shelf without using any masterbatch, just recycled plastic,' says Zoe Brimelow, Brand Director at Duo.