Recycling superabsorbent polymers

Dr Michael Ford MIMMM at Haseltine Lake Kempner explores patents relating to the recycling of personal, disposable, hygiene products.

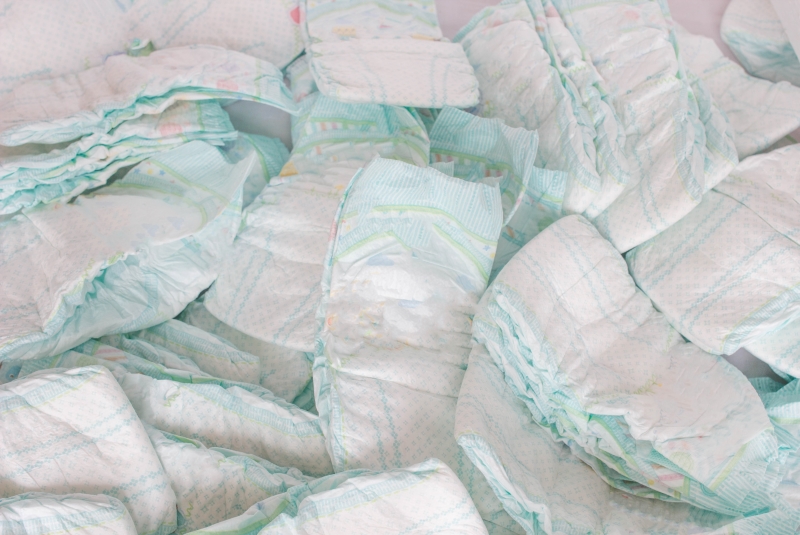

Recycling personal, disposable, hygiene products (such as nappies and sanitary pads) can be challenging due to the superabsorbent polymer (SAP) filler materials used.

SAPs, also known as slush powders, are hydrophilic polymeric materials that can absorb and swell to retain large volumes of aqueous liquids. These materials fall into three main classes – crosslinked polyacrylates and polyacrylamides, cellulose- or starch-acrylonitrile graft copolymers, and crosslinked maleic anhydride copolymers. Those based on crosslinked and partially neutralised acrylic acid being the most commonly used. Crosslinking is necessary to avoid material dissolution following water absorption and to form stable hydrogels for trapping liquid.

When personal hygiene products are recycled, accumulated soils are removed, and the remaining waste is broken down into its constituent components. Cleaned SAP components can be reused in less demanding applications, for example, as agricultural or horticultural water-retaining agents or for industrial waterproofing. However, recycling of SAPs for use in new personal hygiene products or other high-value applications requires degradation and/or depolymerisation of the crosslinked, polymer network in such a way as to produce high-quality poly(acrylic acid) (PAA) for blending into virgin SAP.

Known methods for depolymerising SAPs typically use UV or ultrasonic radiation or heat. Unfortunately, methods based on UV irradiation can be slow. These also tend to cause preferential scission at the midpoint of the polymer chains, such that higher molecular weight chains are degraded at a greater rate than the lower molecular weight chains. In addition, there is a minimum molecular weight below which degradation or depolymerisation does not occur. Thermal methods have also been found to decarboxylate acrylic acid moieties, making them unsuitable for further use, and produce large quantities of moisture that must be removed in an energy-intensive dewatering step.

However, in 2022, The Proctor & Gamble Company was granted two European patents that seek to solve these problems – EP3783054B1 and EP3783056B1.

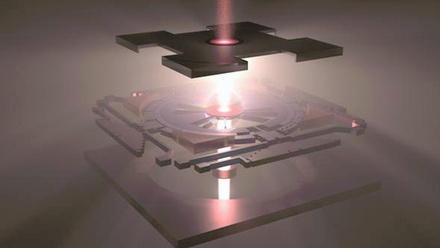

EP3783054B1, entitled Recycling of superabsorbent polymer via hydrothermal microwave processing, claims a method for degrading an SAP to PAA using microwave radiation. A feed containing SAP at a concentration greater than 3wt.%, and hydrogen peroxide at a concentration greater than 0.5wt.% of the SAP concentration, is placed in a reactor and irradiated with microwaves for between two and nine minutes at a temperature of 200°C. The microwave radiation requires a microwave total energy of less than 50MJ/kg of SAP. The resultant product contains PAA at a carbon yield greater than 90%.

According to the patent, microwave-based degradation, as compared to thermal degradation, achieves no or minimal decarboxylation of the acrylic acid moieties when carried out in the presence of free, radical-producing compounds (such as hydrogen peroxide) at short residence times.

The inventors posit that microwave irradiation causes rapid heating of polar molecules, which accelerates the generation of free radicals, and also the necessary chemical scission reactions for polymer degradation, especially in the presence of a free, radical-producing compound. In contrast to thermal degradation, it has also been found to enable improved control of the reaction temperature, as well as to allow energy to be directed near bonds of interest.

EP3783056B1, entitled Recycling of superabsorbent polymer via UV irradiation in flow system, claims a method for degrading SAP to PAA using UV radiation. A feed stream comprising SAP at a concentration greater than 1wt.% is flowed into a UV irradiation zone with a residence time of less than 120s. Similar to EP3783054B1, the UV requires a UV total energy of less than 50MJ/kg of SAP.

The patent describes that UV-based degradation of SAP to PAA, without decarboxylation, is much more pronounced when the SAP feed stream flows while being irradiated, as compared to static SAP irradiation. The inventors suggest that stresses generated in the flowing feed stream cause stretching of the bonds, which lowers the UV energy required to degrade the SAP and/or accelerates the kinetics of the degradation.

The applicants also found that UV irradiation degrades the crosslinked SAP more quickly and, to a larger extent, than branched or linear PAA. It is therefore suggested that SAP degradation occurs close to crosslink points between the crosslinker and acrylic acid polymer, and that SAP degradation requires less energy than PAA degradation.

PAA produced by UV-based degradation of SAP was also found to have a benefit over commercially available linear PAA.

The recycled PAA, when incorporated into virgin SAP, resulted in a lower amount of extractables (measured by the extractable polymer EDANA method NWSP 270.2.R3). This suggests that the recycled PAA was more highly branched and thus more able to be incorporated into the virgin SAP, without slipping away from the SAP material during the extractables test.

Read the patents at bit.ly/3JLURZg and bit.ly/3CXMvd6