Recyclable adhesives could advance foetal surgery

A chemical alteration in polymers derived from alpha-lipoic acid – a small molecule that aids cell metabolism – could enable high-performing adhesives in foetal surgery.

Most commercially available polymer adhesives have 'specific, sometimes narrow, uses', say researchers from Berkeley Engineering at the University of California, USA. So, they believe the recyclable adhesives they have developed using alpha-lipoic acid (αLA) could be a 'game-changer' and adapted for consumer, medical and industrial applications.

After 'slightly altering' the chemical composition of the small αLA molecules, the researchers developed a 'family of monomers' by mixing and matching them together in different ratios.

In turn, they formulated a medical adhesive that acts like a surgical superglue; a pressure-sensitive adhesive, like those used in sticky notes, labels and tape; and an epoxy-like structural adhesive.

'Each application demands unique properties and identifying optimal formulations was the greatest challenge,' says Professor Phillip Messersmith at the University.

'Fine-tuning monomer composition to optimise the properties for each different application involved months of trial-and-error testing.'

Postdoctoral researcher Subhajit Pal adds, 'I don’t know of any other adhesive system or family where you can mix and match a couple of monomers together in different ratios and get this range of adhesion systems.'

They carried out benchtop experiments to measure the surgical adhesive’s performance against an existing surgical sealant and a medical-grade cyanoacrylate superglue. They then assessed its practical application for foetal surgery in the laboratory.

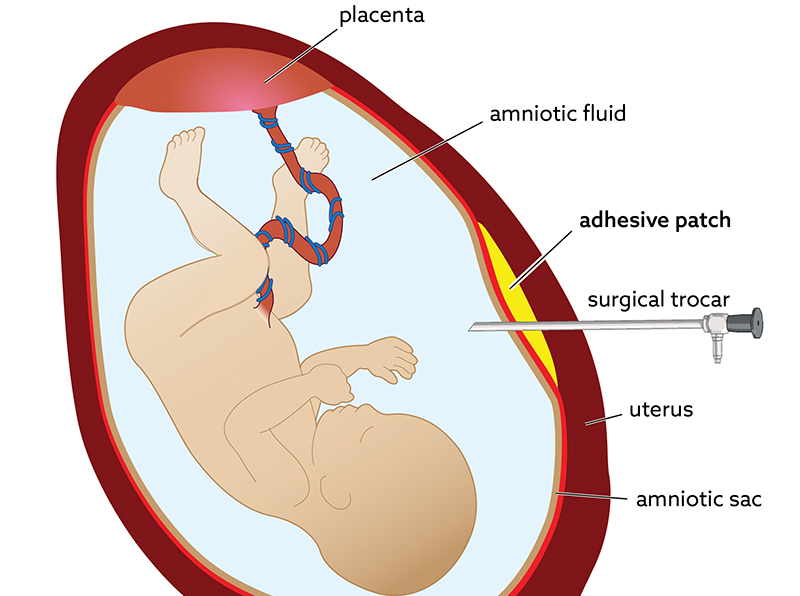

One of the risks associated with surgeons making an incision or small hole in the womb’s amniotic sac to repair congenital foetal defects is that the sac can subsequently rupture, leaking fluid. The sac can also become infected, increasing the risk of pre-term delivery and foetal death.

To minimise this risk, surgeons could try to seal foetal membranes by applying a medical adhesive once the procedure is complete, but no adhesives have been medically approved for this procedure, explains Messersmith.

'Our long-term goal is to develop a sealant that can be used to mechanically seal the defect, prevent rupture and pre-term delivery, and extend gestation,' he says.

To test the feasibility of the adhesive, the team explored a ‘presealing’ approach in an animal model.

'We surgically exposed the uterus of a pregnant mouse and [after placing the adhesive on its tissue] punctured the uterus and amniotic sac to mimic the puncture created during foetal surgery, then compared foetal survival for unsealed and sealed sacs,' he says.

In what they believe is the first procedure of its kind in a preclinical study, the researchers report the adhesive has successfully sealed the amniotic sac ruptures and increased the foetal survival rate in the mouse model from 0% to 100%.

Messersmith says a start-up company has been formed to commercialise the surgical adhesives, but further preclinical and clinical trials are required.

Meanwhile, after testing the pressure-sensitive adhesive, they found it functions well in both dry and wet conditions and reportedly surpasses the performance of conventional pressure-sensitive adhesives.

In one test, an αLA polymer, adhesive film bonded to stainless steel took more than seven days to fail under a static load of 1kg, whereas a conventional polymer made of butyl acrylate and acrylic acid failed in less than two minutes under the same conditions.

Next, the researchers created an epoxy-like structural adhesive by adding calcium lipoate, a salt of αLA, giving the normally soft, elastic αLA polymers an epoxy-like rigidity and strength. The resultant structural adhesive is said to have shorter curing times and better adhesion performance in the presence of water.

Messersmith adds, 'Our αLA adhesives can be broken down into αLA monomers after a product life, using a simple two-step aqueous treatment. The recovered monomers can then be used to fabricate a new polymer for another life.'