Purifying water from fog

A metal mesh has been produced that collects water from fog and simultaneously purifies it with the help of a catalyst.

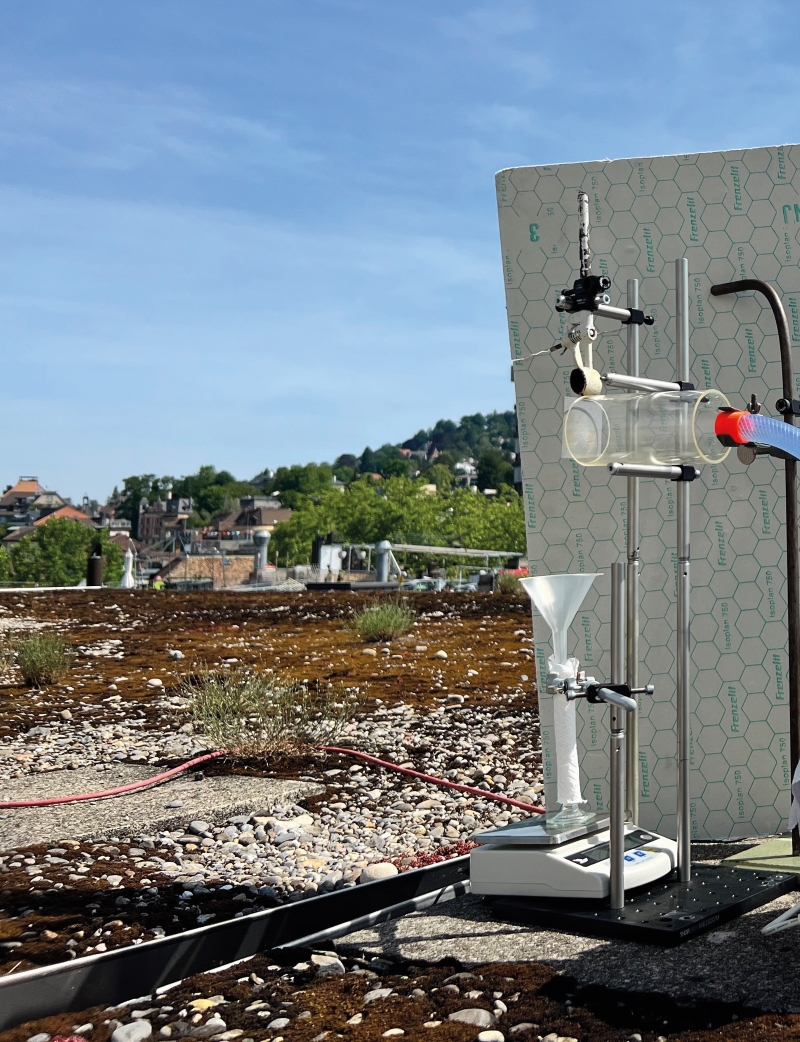

The new fog collector was tested in the lab and in a small pilot plant in Zurich, Switzerland. Reportedly, researchers at ETH Zurich were able to collect 8% of the water in artificially created fog and break down 94% of the organic compounds that had been added to it.

The researchers explain how in countries like Peru, Bolivia and Chile, it is not uncommon for people to hang nets in foggy areas to catch water. As much as several hundred litres of water can be harvested daily using a fog net only a few square metres in area. But the crucial drawback with this method is atmospheric pollution contaminating the water.

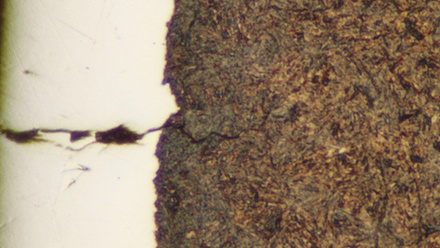

This method uses a close-mesh lattice of metal wire coated with a mixture of titanium dioxide nanoparticles, poly-vinyl-butyral, ethyl cellulose and dichlorodimethylsilane to decontaminate the water.

In addition to harvesting drinking water from fog, the technology could also be used to recover water used in cooling towers.

First author Dr Ritwick Ghosh, of the Max Planck Institute for Polymer Research in Mainz, Germany, conducted the project while visiting the Zurich centre.

He explains that the titanium dioxide nanoparticles are the photocatalyst driving the reaction. The binders – poly-vinyl-butyral and ethyl cellulose – are used to bind the nanoparticles onto the mesh, when the ethanol-based, titanium dioxide nanoparticles solution is used for spray coating.

Finally, dichlorodimethylsilane forms the polymer matrix brush layer on the titanium-dioxide-coated surface to enhance adherence of the coating.

The titanium dioxide nanoparticles are photocatalytic in nature. Ghosh says, 'This means as ultra-violet (UV) light falls on the titanium dioxide nanoparticles, they have sets of electrons (-ve) and holes (+ve) formed on their surface. As a chemical comes in contact with the surface, there is a reaction with these electrons and holes leading to the decay of the chemical.

'In our case, our mesh surfaces are coated with titanium dioxide nanoparticles, which get activated when placed in the sunlight. The contaminated fog intercepts with the mesh fibre, and as the deposited droplet rolls down the fibre to the collector, the chemicals in the droplets get in contact with the titanium dioxide coating and decontaminate.

'As the end product of the decontamination are CO₂ and H₂O, the water is purified after decontamination. The fraction of the chemical that does not come in contact with the coating, or does not dissociate completely, remains in the collected water without decontamination.'

Once installed, the technology needs little or no maintenance, Ghosh says. 'The metal framework is resilient towards mechanical damage, while the polymer matrix helps to have a stable coating that does not wear off against gusts of wind or water impact. The photocatalytic process is a self-rejuvenating process and thus it goes on for long periods without any maintenance.'

Furthermore, 'no continuous energy is required once the set-up is installed'. The only source of energy is sunlight. Half an hour of sunlight is reportedly enough to reactivate the titanium dioxide for a further 24 hours – thanks to the phenomena of photocatalytic memory.

They also report that the catalyst remains active for a lengthy period in the dark, following reactivation with UV.

'The technology is very cheap' at approximately US$3-5/m², adds Ghosh.

He believes it is scalable as the materials are available commercially and the processes adopted for coating are techniques that are widely used in industry.

'The ramifications of this research is the possibility to optimise the photocatalytic memory…[for] round-the-clock decontamination of pollutants using the available intermittent solar energy,' asserts Ghosh.