Protecting the Mary Rose

Sunk while battling the French in 1545, Britain’s Mary Rose warship now faces a new enemy. Mark Glover speaks to Professor Eleanor Schofield MIMMM, Head of Conservation and Care at The Mary Rose Trust, who is spearheading the counter-attack against its degradation.

Professor Eleanor Schofield’s office is also a tourist attraction – The Mary Rose, Henry VIII’s famous warship is her workplace. Understandably though, in the shadow of COVID-19, there are new challenges afoot for conserving one of Britain’s most unique cultural artefacts. The peak visitor period, April to September, has essentially been quashed. It’s a real blow to a business that has always operated on a shoestring budget with much of its income reliant on visitors to the attraction. And with many of Schofield’s staff also furloughed, the pandemic is having an impact on conservation operations.

‘I’ve got two maintainers who are still working in the museum as there are systems we can’t just turn off. These are systems that look after the artefacts,’ Schofield says. ‘From a health and safety point of view, the pipes that feed chilled water all around the museum, you can’t turn them off and leave stagnant water.’

Schofield’s full job title is Head of Conservation and Care. Managing health and safety is just one component of a colourful job description. However, as a materials scientist, the role differs to most of her peers, primarily as the materials she works on are nearly 500 years old.

Sinking to salvage

In 1545, The Mary Rose sank in the Solent, a band of sea in the south of England while engaged in battle with the French Navy. Theories abound to the cause of her demise including overloading, human error and a direct cannonball hit.

What is certain are the 437 years she spent on the seabed before being discovered in 1971, raised in 1982 and then painstakingly transferred to a controlled environment in the nearby Portsmouth historic dockyard. Fortunately, the layers of silt that built up on the ship while it lay on the seabed helped to preserve its structure to an extent, however, as soon as the vessel was raised from the anoxic sea atmosphere to an oxygen-containing environment, corrosive acidic-based compounds went into battle attacking the structure.

To combat this, the ship was sprayed regularly with chilled, recycled water to prevent drying and limit bacterial activity within the timbers. In 1994, it was treated continuously with polyethylene glycol (PEG), a water-soluble solution to reduce wood shrinkage and collapse. Initially a low-molecular weight (PEG 200) was applied, then in 2002, a higher weight solution (PEG 2000) was used to penetrate the wood structure and seal the timber surface.

The sprays were turned off in April 2013 marking the next stage of conservation – the drying process. It is this time stamp that forms part of the latest research into the wood’s degradation, which compares six samples – or cores – taken from the ship with samples during its PEG treatment.

Crucially, the new research shows correlation between metal deposits, sulphur speciation and wood degradation as a function of drying time and depth. It reveals high-oxidised sulphur content up to 12mm-deep into the wood, brought about when the drying hull became exposed to oxygen. ‘As you start the drying process you get more air percolating into the wood,’ Schofield explains. ‘It dries, but you need it to, but that’s when it starts transforming the sulphur. The more time that goes on, the deeper it gets.’

The formation of oxidised sulphur in an oxic environment is a well-known phenomena, however, this study is the first to monitor the evolution of sulphur-based compounds and correlate them with increased wood degradation via the loss of major wood components, or holocellulose.

Significantly, in the most degraded areas, zinc was found to co-exist with iron and sulphur deposits. ‘We know that’s where we’re getting most degradation,’ Schofield observes. ‘It’s a correlation at the moment rather than a causation. We know it’s there and it looks like it’s probably forming something as we are seeing these iron, sulphur and zinc compounds. How much it’s contributing to degradation is something we need to figure out.’

The ship’s varied conservation treatments are being looked back upon to see if any influenced the presence of zinc. Schofield cites the preservation of the Oseberg Viking ship in Norway, where the element was also detected, however the use of zinc treatment tanks was found to be the cause. Seawater, she suggests, could also be a factor.

Meanwhile, the Mary Rose’s conservation prognosis is positive. The findings, Schofield says, indicate that while there was initial change, the degradation has now levelled out and stabilised. Further research is required but she remains confident the insights will help develop a strategy against the compounds to ultimately protect and preserve the ship for generations to come.

Schofield explains that a combination of different variables could influence a future conservation approach, including adjusting the ship’s carefully controlled environments. ‘I’ve wondered if we could broaden these limits. It might be we modify our approach to how it’s displayed in the environment around it. We have all sorts of strands of research going on looking at different treatments, so we can get as many options in our tool-kit to use them as and when we need them.’

On the offensive

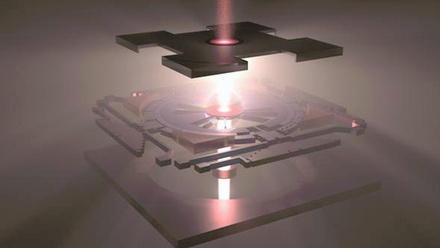

The six samples taken from the ships’s wooden hull were analysed at Diamond Light Source’s Synchrotron Centre in Oxford where a combination of techniques were deployed, including X-ray absorption near-edge spectroscopy (XANES) and X-ray fluorescence (XRF) analysis to determine the location of oxidised and reduced sulphur species. To assess the wood degradation itself, Fourier transform infrared spectroscopy was applied, alongside XRF elemental scanning to analyse the depth of degradation.

Handling materials as old as those in the collection present an array of challenges for Schofield. The very nature of conservation means a material is vulnerable to external influence, particularly when they are in transit for a prologned amount of time. Schofield takes the samples with her to the centre, initially wrapped in cling film and then vacuum sealed in barrier film, but the results gleaned from the synchrotron facilities make the 80-mile journey worthwhile.

A portable XRF machine negates the miles to an extent, allowing some measurements to be taken in-situ, but it has limitations in terms of meaningful data, compared to the insight that Diamond Light help facilitate. ‘The portable XRF will tell you if an element is there but it won’t tell you what form that element is in,’ she says. ‘When you’re going to somewhere like Diamond, the beamline that you’re using can be tuned to look for a specific element…we’ll be able to work out all the different sulphur compounds that are there.’

However, Schofield suggests that it’s in remote technologies, including X-ray diffraction (XRD) and infrared thermography (ID), that innovation in conservation analysis lies. ‘I know there are research projects taking place that are trying to develop portable XRD or ID.’ she continues, ‘Being able to carry XRD in-situ would be amazing.’

Another challenge lies in the lack of destructive testing. In materials science, the technique is common to characterise a material, but when artefacts are nearly 500 years old destroying them is not an option. It means research is often assumptive rather than evidence-based, a process that Schofield, who has a solid CV in materials science, finds difficult to square. ‘We’re very clear about the assumptions we’re making but it means it’s never definite,’ she says. ‘We can’t say for certain if [the wood] contains this much iron because we don’t know. Coming from a background of materials science and engineering it can be quite frustrating.’

How did she overcome this? ‘We’re constantly thinking about all the information and what we want to learn from it,’ she explains. ‘We think about the techniques and think about the order in how we carry them out that, so you are getting the most out of it. For example, if it’s something that’s going to be destroyed then do that right at the end and eek out as much as you can from a small amount of material.

Potential in collaboration

Collaboration comes in many forms for Schofield. Strategic partnerships with universities, museums and facilities are approached partly with funding in mind, but it is the work with other scientific disciplines she finds most satisfying. ‘I would say it’s one of the main things that I enjoy about my job,’ she says, ‘I’ll flip from working with somebody on an iron corrosion project to then looking at some electrochemistry to then looking at the structural stability of the hull. It can be quite crazy sometimes.’

The by-product is that the term heritage science is now more common in scientific circles, primarily because the area, evidently, is so broad. By straddling an array of disciplines, Schofield hopes knowledge can be shared across the spectrum. ‘There’s a huge resource here and I think we’re just starting to tap into it. I can’t really think of a subject area that we don’t encompass in some way,’ she notes.

However, when collaborating with other materials scientists, she is careful to identify those without a conservation background. ‘If I’m going to look at developing a new material, I don’t need someone who’s in heritage. I need someone who’s good at making that specific material and then they just adapt. What’s wonderful is they come at it from a completely different angle, so they’ll challenge things in a way that I maybe wouldn’t.’

Not an average workplace

Schofield tells me rather tongue-in-cheek that her workplace is like any other with IT issues, meetings and deadlines to deal with. However, when I glance up from my desk, I’m not met with one of the most famous battleships in the world. It is not surprising to hear then, that she sometimes has to pinch herself as she goes about her day-to-day work. ‘If we do work on the ship floor – which is not all the time, but if we do – you focus on your team’s safety and the tasks you’re trying to get done, there are moments when I’ll stop and think, “I’m stood on Henry VIII’s warship,” she pauses to laugh slightly. ‘And it’s all quite bonkers.’

Links to the past

Among the 19,000 artefacts recovered from The Mary Rose were three brass links, believed to be part of a suit of chainmail armour worn by those onboard to protect themselves in battle.

Now, a team led by the Universities of Warwick and Ghent has analysed the surface chemistry of the links to reveal the extent of corrosion and also the compositional make-up of the pieces, suggesting Tudor manufacturing processes were ahead of their time.

‘Brass production was fairly well controlled and techniques such as wire drawing were well developed,’ says Mark Dowsett from the University of Warwick’s Department of Physics. ‘I was surprised at the consistent zinc content between the wire links and the flat ones. It’s quite a modern alloy composition.’

After recovery in 1982, the brass links were subjected to different cleaning and conservation treatments to prevent corrosion – distilled water, a benzotriazole (BTA) solution, and cleaning followed by a coating with BTA and silicone oil.

The research also analyses the surface chemistry of the materials to assess and compare the levels of corrosion between the different techniques, finding that all had been effective at preventing corrosion.

‘The analysis shows that basic measures to remove chlorine followed by storage at reduced temperature and humidity form an effective strategy even over 30 years,’ Dowsett reveals.

From Stanford to Starboard

The time has most definitely come when people need to stop and have a hard look at the environment they’re in and imagine how someone who is slightly different to them might feel in that. If there’s things that you think will put them off, then they need to be changed.

Professor Eleanor Schofield MIMMM, Head of Conservation and Care at The Mary Rose Trust, on her route into conservation, the pleasure of materials science theory and encouraging equality in the sector.

How did you make the jump from materials science into heritage and conservation?

The common thread throughout my career has been the use of synchrotrons. After graduating from Imperial College London with my MEng and PhD in materials science, I became a Post-Doctoral Research Associate at Stanford Synchrotrons Radiation Lightsource in the USA.

I came back to the UK to the University of Kent who were working with The Mary Rose at the time. While I was there, a job advert came up for a materials scientist in conservation who had experience with using synchrotrons. It was one of those job specifications where I could tick off everything that was required and it just looked really interesting.

From there I started noticing other conservation jobs which began to catch my attention, I left research for nine months, working in science publishing at Elsevier, but then the Conservation Manager at The Mary Rose Trust in Portsmouth came up so I went for it.

How can equality be encouraged in materials science?

Perhaps the question should be what the sector can do to make itself more appealing to people to join it who aren’t represented there. So I would widen it out from equality to anyone who doesn’t quite fit the…I don’t know what you want to call it…the standard?

The older I get I become acutely aware of the massive privilege I’ve had in my life. Yes, I am a woman working in this field. I’m also a straight, white woman with no disabilities with a good upbringing. I have worked hard, and I do work hard, but I’ve not had a perfect life and hard things happen but I’ve never had to face any of these other things that people are facing.

The time has most definitely come when people need to stop and have a hard look at the environment they’re in and imagine how someone who is slightly different to them might feel in that. If there’s things that you think will put them off, then they need to be changed.

It starts with being really, really honest. We all collectively need to stop and look. It can’t all be on the people of colour, for example, it can’t be on them to do it and they shouldn’t have to.

In the past it has felt like how people bend to fit into this fixed environment, but why does that environment have to be fixed that way. Why should it be? It was moulded upon straight, white men basically and there’s a lot of people that don’t fit that narrative.

I think I’ve had it relatively easy but that’s not to say I’ve not had misogynistic comments made, and the annoying thing is I look back at things especially when I was younger and think I should have said something.

What can young people look forward to when getting into a career in materials science?

The thing that appealed to me about materials science was that it was so clear, the use of it. And I’m not saying that other subjects aren’t useful, of course they are, but the practical side of it. That you would need that for this and you could develop a new material for that and there are so many different applications, like a plane or in sport...I think because of that it was often very easy to explain it in layman terms to people which I really enjoy as well.

Why are materials chosen to do a certain thing and how you can change it slightly to do something different? It’s amazing and never ending. When I saw materials science as a discipline when I was applying to go to university, I hadn’t heard of it before and even when I asked teachers at school about it, they hadn’t heard of it either. It’s a bit random really but the more I heard about it the more it appealed.

Materials science is right on that intersection of science and engineering. A lot of the work I did initially was more on the physical sciences side. My partner, who’s an aeronautical engineer, suggests I’m doing engineering all the time, looking after the ship and its stability. He said to me once, ‘So you might do your experiment and work out your chemical reactions of something, but as soon as your putting that into some form of treatment and applying that to the artefact then that’s engineering.’ And I was like, ‘Oh yeah.’

It’s all of these things – how to make a new material, and the properties you want it to have and then through to the engineering level. How are you going to make it? How are you going to get it to do what you want to do?

Is there one person who’s inspired you?

I’m not really sure there is one person. I think I’ve realised that over the course of your life and career it changes to what you need.

I kind of feel this way both personally and professionally. I just don’t think there’s one person in this world that can give you everything you need. Professionally you need different things at different times.

I feel very lucky that I have a very wide network of people from different disciplines so there’s never a time when I think there isn’t somebody I can call on, whether it’s a work-related question, or a professional development query, there’s always someone who I think I can ask, which, actually, is a lovely thing to realise.

Where do you see yourself in the future?

There’s a work colleague of mine at The Mary Rose who recently celebrated working there for 40 years and having turned 40 myself a couple of months ago I found it equally brilliant and a bit worrying.

The thing is, the whole project is changing so much. Since I’ve started, we’ve had one little museum and a ship hull and then they got combined and we had a bigger museum and there was different configurations through that and then we’ve had temporary exhibitions. It’s like working for separate companies so in that respect I can see why people stay on here.