Polymers, heal thyself

A polymer that can fix itself after it has been cracked or broken into pieces is on the horizon, claim researchers at Bournemouth University, UK.

The research team, led by Dr Amor Abdelkader, hopes this could lead to longer-life, plastic-based products, particularly electronics, and reduce waste.

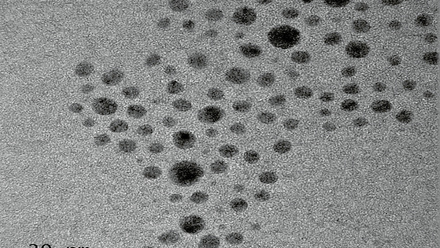

The team has added nanosheets of a titanium carbide MXene (Ti3C2Tx) combined with hydrogel to a polyvinyl alcohol (PVA) matrix. This is said to enhance mechanical properties and enable self-healing.

'We are following the same process as Mother Nature – when you cut your finger, the blood will initially solidify to cover the crack until the skin tissue seals it, and that is what we are doing with our plastics,' explains Abdelkader.

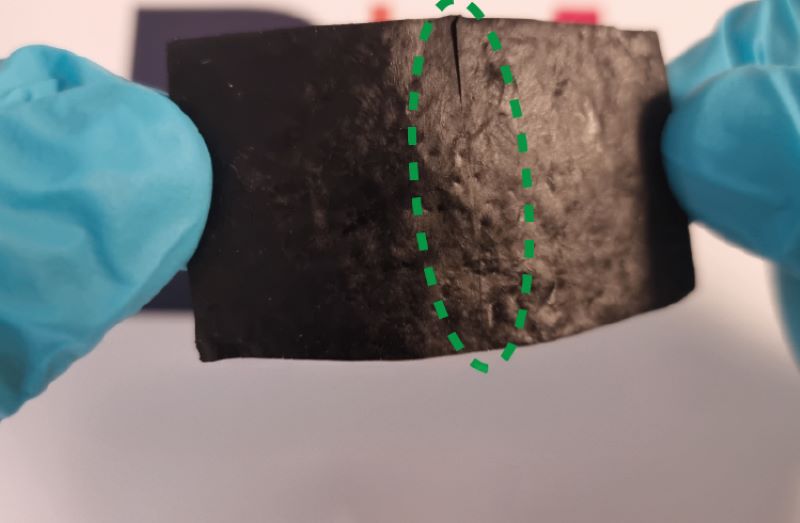

'Adding just 1% (by weight) of k-MXene nanosheets to the polymer matrix triples its tensile strength and grants it a high-healing efficiency of 88.3%.'

The research has also involved 'controlled and tuneable alternation of the surface chemical properties of the nanosheet, which is responsible for enhancing the composite properties', specifically healing efficiency and electromechanical response.

He adds, 'We have tested that and designed new sensors for detecting human motion that self-repair after being subjected to damage. Such a concept paves the way for new-generation electronics that require no, or minimal, maintenance and therefore last longer.'

The MXene with the modified surface has the ability to reconnect with other similar chemical groups present in the bulk.

Exposure to humidity in the atmosphere activates the MXene, which bonds the broken sections back together.

The researchers say, 'Changing the surface properties of 2D materials like MXene is not an easy task, and controlling the surface chemistry is even harder. We were able to control the surface properties of the MXene and replace the fluorides with oxide chemical groups...which has a significant impact on accelerating the healing reaction.'

Furthermore, Abdelkadar says the dry annealing and swelling technique enhances the interaction between the filler and matrix while partially crystallising the polymer. This has led to a nearly four-fold increase in the electromechanical response when used as a strain sensor.

Meanwhile, the sensor for human motion could detect finger bending with a response time to stretching of approximately 548-560ms.

'The sensor shows a gauge factor of 2.09, which is significantly better than those reported by comparable current sensors. Our sensor shows the ability to recover 95.6% of its functionality after multiple healing cycles, by restoring electrical pathways,' describes Abdelkadar.

The team believes the process is applicable to other types of polymers.

The technology is currently under investigation for large-scale production and commercialisation, and the researchers are developing the research to design new self-repairing devices.