Plasticity of ceramic materials enhanced

A technique to improve the plastic deformability of ceramics at room temperature could expand their usage.

Scientists at Purdue University, USA, claim this is possible by first introducing high-density defects in brittle ceramics under high temperatures, and then cooling the material to room temperature to preserve its defects.

Professor Haiyan Wang, who headed up the research team, explains that one of the challenges is that ceramics naturally have few dislocations.

'A dislocation can glide within crystals to enable plastic deformability at certain stress levels,' she explains. 'However, in ceramic materials, it is difficult to nucleate dislocations at room temperature, as the fracture stress in ceramics is much less than the stress on nucleate dislocations at such temperatures.'

Professor Xinghang Zhang adds, 'In contrast, metallic materials are ductile because they easily nucleate a very high density of dislocations. And dislocations are mobile in metals at room temperature, significantly improving their ductility. So, the way to improve plasticity for ceramics is to nucleate abundant dislocations in ceramics before we start to deform them.'

This latest research builds on a flash sintering method the researchers previously developed. The advantage of the new technique, claims Wang, is that it can be generalised to nearly all ceramic materials.

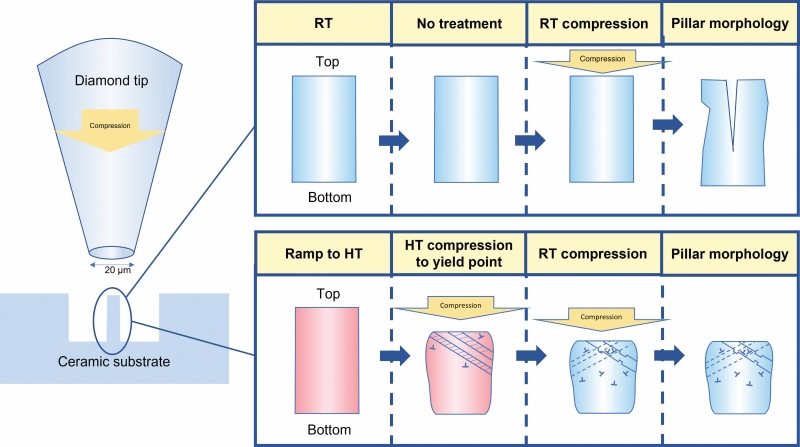

In the paper, Achieving room temperature plasticity in brittle ceramics through elevated temperature preloading, published in Science Advances, the researchers explain how they pre-inject defects into several ceramic systems and pillars of different dimensions, including at the micrometre scale up to 10µm in diameter. These defects include dislocation segments, stacking faults and twin boundaries.

The paper reads, 'These defects allow ceramics to bypass the large critical resolved shear stress required for dislocation nucleation at room temperature. Therefore, when the preloaded pillars containing dislocations were deformed at room temperature, plastic deformation took place.'

For example, they have pre-injected these defects into single-crystal titanium dioxide (TiO₂) and aluminium oxide (Al₂O₃) in the preloading stage. The paper reports on a temperature-dependent study of the defects’ material properties from room temperature to 1,300°C.

The scientists have conducted in situ scanning electron microscopy compression tests and detailed microstructural characterisations of the deformed pillars to examine the impact of the preloading methods on room temperature deformability. From this, they conclude that elevated temperature preloading can be an effective approach to enhance deformability of ceramics at room temperature.

'After the preloading treatment, single-crystal TiO₂ exhibited a substantial increase in deformability, achieving 10% strain at room temperature,' claims Zhang. 'Aluminium oxide also showed plastic deformability – 6-7.5% strain – using the preloading technique.'

The US Office of Naval Research has supported the research, and the next step is to collaborate with industry on large-scale demonstrations using different ceramic systems.