Pathways through materials science

SEC Committee members discuss where their career in materials science has taken them.

Many of us become materials scientists without realising. As a highly applied discipline we draw from all aspects of the physical sciences, and this is reflected in the diversity of backgrounds of those who end up in the sector. Not only does materials science draw from a broad spectrum of expertise it can lead to careers in an incredible number of areas.

Ollie Thomas

I’m a PhD student in the department of materials at the University of Oxford. My undergraduate degree was in Chemistry at the University of Durham, and my first foray into the field of materials science was whilst researching polymer membranes for energy materials during my masters at the CEA in Grenoble, France.

I very much consider myself to be both a chemist and a materials scientist and my current research is on sodium ion batteries. I have found myself drawing upon all areas of my undergraduate education, including the problem-solving skills developed in organic chemistry despite now working very much on inorganic materials. As a researcher one of my favourite things is learning, and I’ve certainly had to do plenty of this, developing my understanding of quantum and solid-state physics to better design and characterise my target materials.

I’ve found that materials science, at its core, is problem solving. We draw from the multidisciplinary expertise at our disposal to develop materials, refine how we make them, and optimise their application. Here I’ve asked some of my colleagues on the student and early careers committee where materials science has taken them.

Anna Tholen

I currently work as a Consultant in the Materials Technology and Research department at TPGroup, a consultancy company specialising in a range of defence applications. In this role I have been able to contribute to a range of exciting projects, including the safe disposal of the UK’s decommissioned nuclear submarines and NATO initiatives to make the world a safer place.

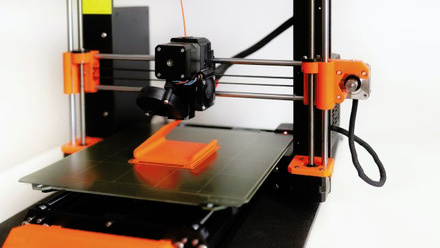

I am still relatively new to the world of materials science, having completed an undergraduate degree in Design Engineering prior to my PhD. My PhD, which involved improving metallurgical properties of tool steel alloys in laser additive manufacturing, only became ‘materials science focused’ in the last couple of years (once I realised quite how important metallurgy was in the role of improving the laser additive manufacturing process!).

By entering the world of materials science, I have learned quite how important it is to understand the behaviour of materials in any project or application. In my consultancy work, materials science is becoming increasingly important in defence projects; so having this dimension of understanding really enriches the output of engineering projects and initiatives. Where design for manufacture, assembly, disassembly and disposal are important, materials science has enabled me to produce higher calibre outputs than my original Design Engineering background would have been able to provide alone.

Dr Aimee Goodall CEng CSci MIMMM

I am currently working in the technical department of Tata Steel UK. I manage a team of problem solvers in the Through Chain Value department. We look at problems that are produced in one area of the works, and then their effects are felt further downstream.

My degree in Forensic Science helps with the problem solving, using facts not opinions and making sure that we get to the root of problems. Work experience in the steel industry helped me to build contact, get knowledge of the business world and grow my confidence in a busy, fast paced environment.

I have a PhD in metallurgy, which has been important to understand the processes we are looking at when solving problems. It gives me understanding of which levers can be pulled to make changes. At also gives me confidence that if I don’t know something I have the ability to learn it.

My formal university experience has given me a strong foundation to start my career. It also has helped me with my knowledge of the area, but for me it is the softer skills I have picked up on the way that have the biggest impact. The of people, knowing how to present my work for different audiences and taking academic knowledge and applying it to an industrial setting.

Liz Scoffins CEng CEnv MIMMM

I got into Materials by accident, ending up studying it for my degree on a deferred- counter offer. To get an understanding of exactly what things are made of was something I’d always wondered about but didn’t realise that I could study.

I use the principles of engineering and science from my degree more than the specific material knowledge. Currently, I work at the Manufacturing Technology Centre (MTC) in the transformation team, supporting small and medium businesses to introduce technology into their business.

One thing that I didn’t think I would use but has come in really handy is how semiconductors work. Actually having a base level understanding is really helping as the focus on electrification increases

Alice Robinson CEng MIMMM

I’m a metallurgist at Rolls-Royce so studying materials science was a huge part of my journey. Whilst at Rolls-Royce, I’ve worked with loads of different materials (steels, copper alloys, zirconium, ceramics and elastomers to name a few) and held various positions, including technical assistant to the Services Director - a role aimed at early career personnel to give them exposure to seniors in the business and an insight into how the business runs and how and why decisions are made.

Whilst not relating at all to materials science and more centred in finance, commercial or business management, I found my skills as a materials engineer/metallurgist really helped me to make the best of the role. From my experience at uni of doing weekly lab reports, and my later experience of digesting literature and or huge datasets, crunching the numbers and relaying trends to interested parties, I was super well equipped to read contracts, proposal documents etc. and generate a slide or two for my director summarising the key info. He always said how impressed he was with how quickly and how well I could digest unfamiliar information and produce exactly what he needed.

As an engineer/materials scientist, it’s so easy to get stuck into the details, and this secondment really helped me to see the bigger picture and start to appreciate it more. I’m recently back in a metallurgical role again and am loving getting stuck back into what I know and love, but I’m really trying to keep that big-picture mentality with me that I learned on my secondment. Whilst I’m not sure what I’ll do next, I think I’ll probably stick around in my current role for a while longer yet. I would say that as an early career materials scientist, you shouldn’t be afraid to move around a bit and only stay in one place as long as you’re still learning and are excited coming into work every day!

Dr Michael Kenyon MIMMM

With my PhD focusing on aluminium alloys, it was only natural for me to seek a role which uses these skills and knowledge and importantly, a sector I enjoy working in. This led me to a role as a materials engineer for Innoval Technology, a technical consultancy to the global aluminium industry. With my day-to-day job involving metallurgical characterisation and testing, I looked to involve myself more with the Institute of Materials, Minerals and Mining and joined the Non-Ferrous & Light Metals Technical Community, and also the Student and Early Career Committee. Exposure and involvement in both these groups has helped me increase my network across various materials industries, expand my knowledge and technical skills in other areas of materials science I wouldn’t have had experience to in my day job, and helped me improve my soft skills, a critical part of developing any career. Even contributing to this article and many other published pieces has helped me develop my communication and engagement skills.

Regarding the materials sector, which is of course composed of multi-material sectors on a global scale, my work is increasingly being dictated by global current affairs and future needs. The obvious area of concern is the fight against climate change and other detrimental environmental impacts, a significant issue for the materials, minerals and mining sectors. The dire need for improvement in more sustainable materials, including the aluminium sector, has led me into the area of sustainability analysis, specifically Life Cycle Assessments (LCA). LCAs have their controversies but the aim of quantitively studying the life cycle of a product, process or service to help improve environmental impact, is critical to improving the sustainability of materials. I would not have thought when I left my PhD 5 years ago, that this is what I would be doing and am excited to see how I can progress my career over the next 5 years.

Sam Burdett MIMMM

In May this year I started a new role as a Carbon Manager at Skanska UK. Not only was this role new to me but it was also new to the business unit that I joined. Understanding the scope of my role has been a challenging experience that has stretched me outside of my comfort zone.

In my role, I work with disciplines from engineering, procurement, estimating, design management and the environmental colleagues in my own team. I manage and work with my colleagues on the delivery of carbon footprints for our building projects in the UK. I also provide technical expertise on materials, construction methods and the carbon impacts of these.

In September 2022 I finished a part-time master’s in Advanced Materials for Sustainable Infrastructure which has given me a fantastic base of knowledge in sustainable development, life cycle thinking and materials science as well as a giving me the opportunity to develop my time management and leadership skills.

I really enjoy working in the built environment sector and am excited about the coming years. The built environment being the homes we live in, the buildings we work in, the factories we make stuff in, and the stores we shop in and much more. Half of all material extracted from the earth each year goes into the built environment. Materials science has never been more important in this sector as we look to decarbonise and adapt to the effects of climate change.