Open for business – commercialising research

Commercialisation is an area of research being pursued by universities up and down the UK. Andrea Gaini speaks to three professionals steering such programmes to find out more.

Panellists

James Baker, CEO Graphene@Manchester, UK (JB)

Adam Stoten, COO, Oxford University Innovation Ltd, UK (AS)

Andrew Tingey, Executive Director, Imperial College Innovations Ltd, UK (AT)

Why do you think commercialising is a good idea for researchers?

JB: Not every researcher is going to be motivated by commercialisation. And some researchers are totally motivated by that fundamental science and fundamental research. If you look at graphene, that didn't come out as a result of a commercialisation process. It was a 'fun Friday', playing with sticky tape and a pencil, driven by curiosity. So, we still want universities to do fundamental science – that real, curiosity-driven, new thinking. And that's core to the university sector.

At the same time, we also need to convert some of that science into products and applications. And that’s where we can bring in organisations like the Graphene Engineering Innovation Centre (GEIC).

GEIC is not staffed by academics. It's staffed by people who may have a PhD in material science but have also got industrial experience. So, for me, commercialising is about getting the right people together in a room and it’s not just the science bit, it’s also all the filling in of forms, applying for grants, applying for loans, registering intellectual property (IP), etc.

Another thing we are working on, is making sure that academics get credit for their commercialisation, because if we can demonstrate that a key part of an academic’s career is commercialisation, then that will motivate academics to take more interest and focus on this area.

AS: Modern academic research has societal impact as a major goal and translating the outputs of research into new products and services is a great way of generating this. In years gone by, there may have been a degree of stigma associated with academics engaging with industry, the vast majority of researchers today see translation and commercialisation as an integral part of being a world-class academic.

While the primary motivation is usually societal impact, there can also be financial rewards for researchers associated with commercialisation. Oxford University sets out in its regulations what share of future royalties from a given deal will be given to academic inventors.

AT: I’d prefer to use terms like applying, generating impact or translating – the word commercialisation sometimes has negative connotations for people, although it can be the primary reason why researchers are looking to explore this area. These days it’s not an either/or situation, many academic colleagues pursue commercial interests that sit happily alongside – and in many cases reinforce – their academic careers.

Looking for impact has become mainstream and a translational strategy is often a core part of grant applications. In terms of why people are interested, it could be factors such as an interest in how research results could solve problems faced by industry, a general interest in IP and how it works, a desire to help patients (for medical applications), to achieve commercial success, or simply to do something new and different outside the usual academic environment.

How do you protect IP?

JB: With graphene today, we’re increasingly seeing that it's more 'know-how' and isn't a patentable thing. GEIC is trying to support people to get value from their IP, [to help them] get some return from it, rather than trying to own it and stifle it.

AS: Oxford University Innovation (OUI)’s role is to work with researchers to help them understand whether their innovation potentially solves a meaningful problem, what the commercial market might be for their solution, and whether we can manage or protect the associated IP in a manner that will facilitate finding a partner or investor.

If the answers to each of these is yes, then OUI is able to pay for the filing of patent applications to protect the IP. We work with a wide range of patent attorneys in different technology areas to provide the requisite expertise. Beyond patents, we also commercialise innovations for which the IP is non-patentable, but still useful, for example, the copyright in software source code, or even database rights.

AT: I think some thought needs to be given to the type of IP appropriate to the project – IP is a lot more than just patents. Software, for example, can often be protected by copyright – or there could be design rights, or know-how that is not in the public domain. When we know more about the technology and the situation, we can think about the right type of IP. If the IP is to be registered, for example, by filing a patent or a registered design, we engage external professionals to draft and file the appropriate documents. This ensures we file high quality IP and give ourselves the best chance of being able to partner or attract investment for the asset in the future.

How do you approach IP on collaborative projects?

AS: Academics are highly collaborative, and where IP is generated with the input of researchers from other institutions, the normal approach is to decide which institution is best placed to lead the process, and then for that institution to take assignment of the rights owned by others, so that a single party is able to market and negotiate deals on the IP. The assigning parties will typically receive a share of any future revenues associated with commercialisation of the IP.

AT: It depends. There is no one size fits all solution, and it depends on the partner, who is contributing what to the project, the overall objectives, etc. Every situation is different. There are a number of more common models we can use, and we have to strike a balance between not holding anything up and not committing to fudged, unclear or conflicting terms that will simply store up problems for later.

How is a proof-of-concept developed and what is required from a project before it can convey these plans?

JB: This is based on the principles that I call make or break. It can take you many years going through the cycles to take a product to market. But at GEIC, we have been working on using our facilities to do very rapid design and speed up the process. So, we start by figuring out how much graphene we need to add, what formulation needs to go into a rubber to then produce prototypes or sample material rapidly, to then test and iterate that innovation cycle once, twice, 10 times, 50 times.

We discuss the risk and reduce the overall time for a product development. They're all quite rapid. You get an idea, make something, test it. If it works, then develop it, or if it fails – fail fast, learn and move on to really challenging the whole innovation cycle for a new material.

AS: Much of the IP disclosed to OUI is early stage and needs proof-of-concept work to take it to a level of maturity and validation required to attract a commercial partner. Our proof-of-concept funds are therefore invaluable in undertaking such work. [They are] based on feedback we have received from potential partners to help define exactly the experiments we need to conduct for the IP to be market ready. The nature of this work varies greatly depending on the technology, but OUI is fortunate in having a £5mln fund to support this work, typically granting awards of a few tens of thousands of pounds, but in exceptional cases up to £250k.

AT: Again, this is very dependent on the technology. Proof-of-concept in medicine means a very different thing than in process chemistry for example, there is often no such thing as the experiment or test result. Proof-of-concept is usually about de-risking a project enough to attract the next tranche of funding from whatever source – and it is important that sources of this funding (which is, by its nature, very high risk) is available to fledgeling projects. When considering publishing, it is important that IP aspects are considered because a public disclosure can seriously affect our ability to protect inventions by filing patents.

What defines which project gets licensed and which ones become spin-outs?

JB: Manchester University does have some intellectual property or family of IP, which is available to licence. But GEIC tends to be more about creating something with the idea. So, there is some background IP, but our business model at GEIC is that the partners own the know-how, and we get a royalty.

AS: OUI always tries to define the optimal route to market for a given technology. In some cases, it may be obvious from day one that a technology has the potential to support a standalone new business, whereas others may only ever be destined to be a bolt-on licence for an existing enterprise.

For others, there could be opportunities to go either way, in which case, the entrepreneurial interests of the academic inventors may determine whether a spin-out is formed or not. With the increasingly entrepreneurial culture in the university, coupled with greater support for this activity, spin-outs are becoming an attractive option for academics, although often represent a much more time-consuming activity.

AT: It is all about dialogue with the inventors, although there are certain characteristics which may favour one or another route. It’s important to know that the IP is always licensed, it’s a question of whether the licence is to a third-party or the inventors’ own start-up.

Typically, if a project is niche, or requires specialist resources to develop it, or there are already dominant market players in the sector, a third-party licence would be appropriate. Conversely, if the inventor really wants a start-up, the technology is more of a platform, or the sector is one in which a start-up can make an impact, etc., then it would be appropriate to think about a start-up. It’s important to fully discuss and agree the way forward with our academic colleagues.

What support is given to academics on this entrepreneurial journey?

JB: We have a graphene post-doctoral course, and we support that with a commercialisation course. And so, 10% of their year two, or year three, is devoted to commercialisation. We have speakers who come along who talk about commercialisation and pitching your ideas.

AS: OUI supports academics to understand the market for a technology and the likely licensees or investors. Where a spin-out is the desired route, we can help academics develop a business plan, identify potential executive management and approach investors. At Oxford, we have an associated venture fund, Oxford Sciences Innovation, that has raised more than £600mln to invest in Oxford spin-outs, so they also represent a great source of both capital and expertise.

Even before an academic makes the discovery that might one day become a spin-out, the University provides increasing opportunities for entrepreneurial training via the Oxford Foundry – the recently-established student entrepreneurship centre – and the Said Business School. OUI also runs an Innovation Fellows programme to help budding academic entrepreneurs understand more about the nuts and bolts of commercialising IP.

AT: At Imperial, the support we give ranges from the practicalities of organising IP protection and commercial discussions, through to advising on business plans, providing entrepreneurial training, access to seed investment funds, incubator facilities, consultancy advice and specialist support on working with industry. Whatever our academics are interested in doing, we can help them.

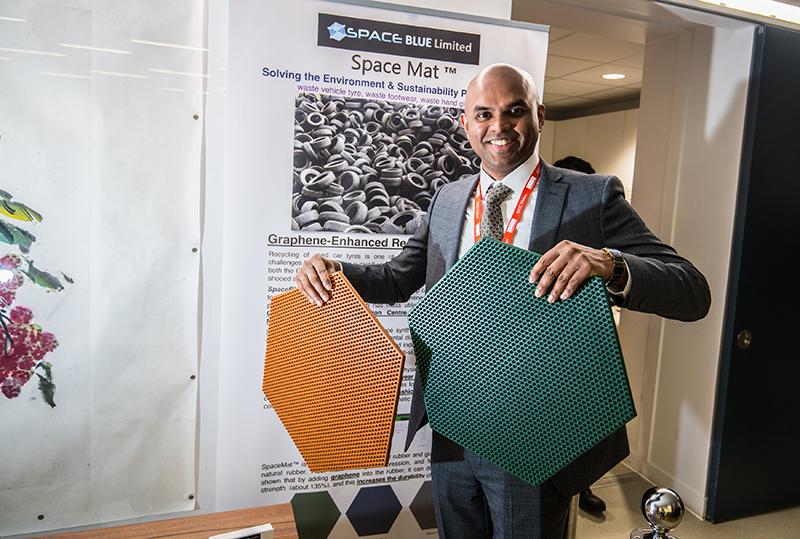

Spinning out of waste

Born from a desire to tackle tyre waste, SpaceBlue is a spin-out company from the University of Manchester, UK. Andrea Gaini catches up with its CEO Dr Vivek Koncherry.

‘Inventing stuff is my hobby, [and I don’t just work with] rubber products or composites, I also do robotics, artificial intelligence and many different types of inventions,’ says Dr Vivek Koncherry, an Impact Fellow at the University of Manchester, UK.

And so in 2019, when reports started flooding in about copious amounts of waste rubber from used tyres being traded with Eastern countries instead of being recycled, Koncherry immediately thought of an idea to tackle the issue.

Within a year, he had launched the first prototype of the SpaceMat. The floor mat, which is suitable for outdoor and indoor spaces, is made using 80% of waste tyre particles mixed with 20% graphene-enhanced natural rubber, which is then compressed under heat and pressure inside a mould.

Koncherry explains that using graphene solved the problem of reduced performance often found in recycled materials. He says that graphene enhances the rubber’s durability and creates a sustainable product that is also high quality.

By using just a fraction of a percentage of graphene, Koncherry also managed to increase performance and eliminate a common issue in floor mats – the weak binder material that causes rubber crumbs to fall off the edges.

Adding graphene to the chopped tyres and polyurethane, made the binder strong enough to hold the tyre particles and increases the rubber's strength four-fold, essentially solving the issue at its root.

Negating the end-of-life consequences was also a priority for Koncherry. He says that in the same way that waste tyres are chopped up to create the mats, the firm can recycle the mats and create new product from it.

On the mat

On the UK research sector, Koncherry says it is ‘world-class’ but lags behind other countries when it comes to commercialisation. ‘Traditionally, the scientific community in the UK is focused on fundamental research and not commercial products,’ he admits.

The Graphene@Manchester programme aims to tackle this and ensure that Manchester and the UK play a leading role in developing the potential of graphene. James Baker, CEO of Graphene@Manchester, describes how since the material's first isolation in 2004, the UK has built a great reputation for inventions, and now it’s time to put that to fruition.

Baker says that their work is to help people who have great ideas and that need technical or business support to succeed. ‘We're trying to build an ecosystem of people making graphene and using [it to make] products…a graphene city. He says, ‘We want Manchester and the north-west of the UK to be known for its reputation for inventors [and] for innovators.’

Koncherry adds, ‘The challenge is the investment from start-up to medium-scale company. There is a gap, and bankers and investment firms don’t want to take the risk.’

Therefore, once developed into a viable prototype, Koncherry made contact with the Graphene Engineering Innovation Centre (GEIC) about his idea, prompting Baker's involvement. ‘James loved the idea and immediately decided to back the project,’ Koncherry explains.

Normally, for Koncherry, such inventions would have been a hobby, but Baker’s enthusiasm pushed the idea towards something he had never really imagined – commercialisation.

SpaceBlue took flight. Koncherry received funding for the testing and validation of his SpaceMats from the Bridging the Gap, European Regional Development Fund (ERDF) – a programme that engages Greater Manchester-based SMEs to explore and apply graphene and other advanced 2D materials in a range of applications.

Looking ahead, Koncherry says challenges exist around their use of an international supply chain. Mats are produced in India, where 500,000 units are created every month. ‘Currently, we make and send a pre-mix graphene to a third-party factory in India that already has several compression moulding machines.’

He explains that initially his main goal was to get a finished minimum viable product to market at the lowest cost possible because he didn’t have any investors, but moving forward, he says that ‘because waste tyre is in the UK…we want a factory in Manchester’.