New heights for magnesium supply chains

How lightweight, durable and efficiently manufactured alloys could reduce the lead times for aerospace components.

The imperative for high-efficiency transportation systems, characterised by their eco-friendliness, cost-effectiveness and sustainability, poses an unprecedented challenge for the transport industry.

This challenge is further heightened by the drive for decarbonisation, supply chain disruptions stemming from the COVID-19 pandemic, and the escalating demands for growth.

The Paris Air Show of June 2023 showcased the burgeoning demands in commercial aviation and military technology. However, behind the scenes, industry leaders were open about a persistent issue – prolonged and uncertain lead times in delivering crucial aircraft and weapon systems components.

While initially linked to pandemic disruptions, the struggle to secure components from strained supply chains remains a significant industry-wide issue, causing unacceptable delays across various sectors, including the foundry industry.

Did you know?

For its 54th edition, the Paris Air Show brought together nearly 2,500 exhibitors with 30 start-ups featured.

The proverb “necessity is the mother of invention” rings truer than ever as the industry invests in training, digitisation, and lean manufacturing. However, issues with the global supply chain and labour shortages continue to exacerbate the problem.

A viable avenue to diminish the carbon footprint and enhance the efficacy of transportation systems involves a strategic focus on reducing overall weight, optimising material processes and having a reliable supply chain.

Lighter touch

According to a study from the Zürich University of Applied Sciences, it takes ~0.2kg of fuel to transport 1kg of weight over 1,000km. On applying these findings to large commercial aircraft with an unladen weight of ~270t and jet fuel at US$697/t (as of January 2024), even a modest 0.37% reduction in weight (1t) would yield savings of ~US$140/1,000km. Extrapolating this to the longest current range available – up to 15,000km – could save US$2,100 (3t of fuel) on a single flight.

This impact is even more significant for military aircraft, where enhanced performance and payload capacity are critical.

This is even before factoring in emissions reductions from weight loss. Given that 1t of jet fuel generates approximately 3t of CO₂, in the above example, 3t of fuel saving could also reduce CO₂ emissions by around 9t.

The bottom line is clear – weight savings directly correlate to substantial economic benefits, operational advantages and reduction in CO₂ emissions.

In turn, in support of original equipment manufacturers (OEMs), Luxfer’s UK-based division, Luxfer MEL Technologies (LMT), has developed an alloy-specific manufacturing route. This can dramatically reduce the lead times for lightweight components from multiple months to weeks or even days.

Reducing lead times

Magnesium is the lightest structural metal with around two-thirds the density of aluminium and one-quarter that of steel. It presents impressive strength-to-weight ratios, making it suitable for weight-reduction applications. Their alloys also offer good thermal conductivity, electromagnetic shielding and dimensional stability.

The US Federal Aviation Administration has conducted extensive studies and testing on magnesium alloys, with flame impingement temperatures of up to ~600°C. Tests illustrated that the new generation of Elektron Magnesium alloys self-extinguish and are flame-resistant.

Lightweight magnesium alloys play a crucial role in aerospace applications, especially in the form of sand castings – whereby molten metal is poured into a sand mould to create a component. With short lead times, these castings are required for newbuild programmes to minimise costly maintenance downtime and to support new prototype development cycles. However, due to supply chain issues generally affecting the foundry industry, lead times are often too protracted.

Ensuring any casting or component is fit-for-purpose, especially in the safety-conscious aerospace sector, involves strict adherence to international specifications encompassing chemistry and mechanical properties. Quality assurance is assured by adhering to good manufacturing practices, verified by destructive and non-destructive testing (NDT).

Moreover, qualifying a component involves extensive and expensive testing to prove performance, safety and design life requirements. Consequently, any changes in alloys and/or manufacturing routes can be expensive, time-consuming and require a sound business case to progress.

Minimising changes to alloy properties, while improving manufacturing lead times, would therefore be beneficial in reducing risk.

LMT has introduced the concept of machining components directly from large direct chill (DC) cast slabs, while concurrently achieving the same mechanical properties as the established sand-cast alloy. In the DC process, molten metal is poured into a water-cooled, permanent mould, facilitating continuous withdrawal of slab sections.

By introducing a certified DC-cast slab material, LMT aims to expedite the component manufacturing process, potentially reducing customer lead times from many months, to weeks or even days.

While machining components from solid slabs of metallic alloys is common practice, the properties of the initial material can vary between commonly used wrought alloys or DC cast material. As a result, different alloys need to be specified and approved for different manufacturing routes.

Achieving specification properties in DC cast slabs identical to established sand-cast alloys minimises the risk of changing manufacturing routes and enables interchangeability between suitable castings and machined-from-solid slab components.

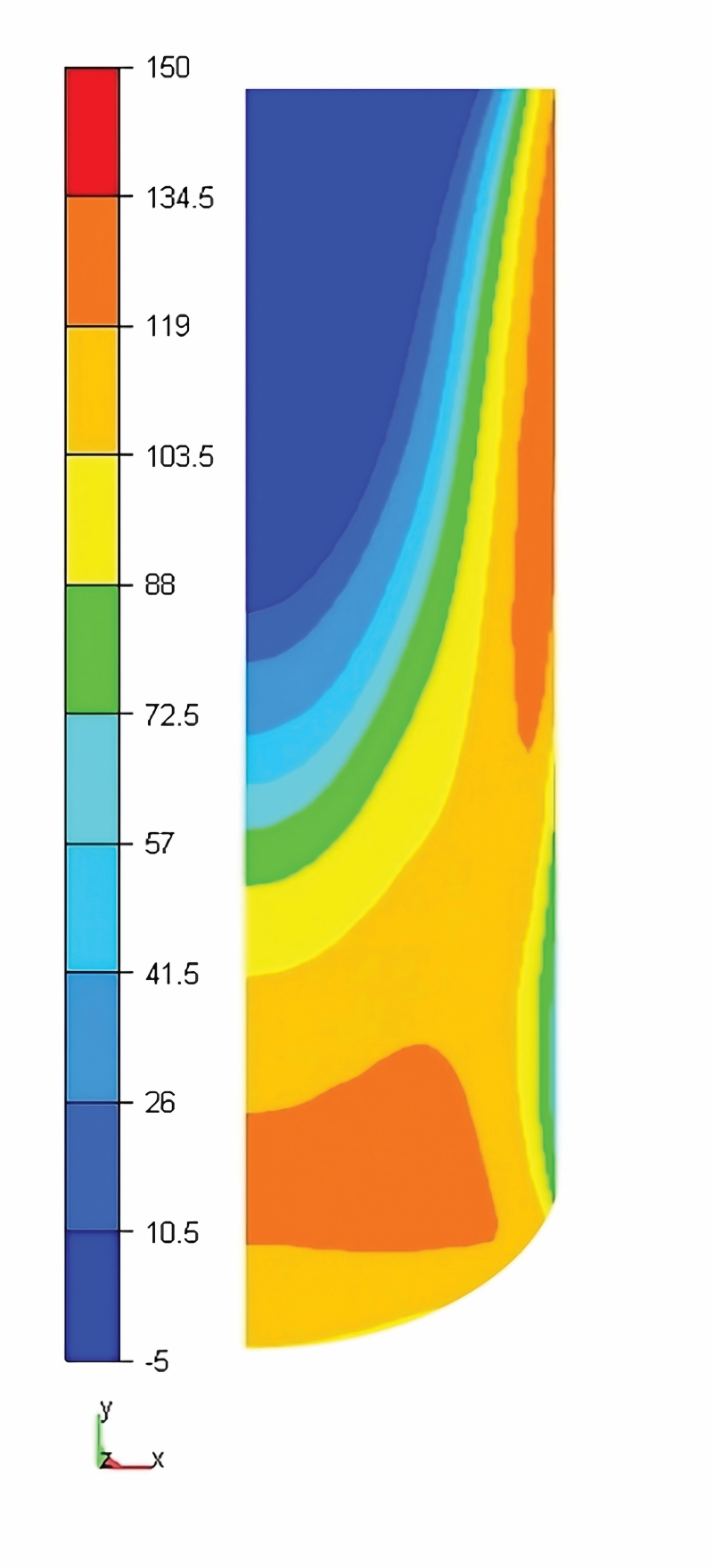

The solidification rate is a crucial parameter affecting the mechanical properties, and differs for small-section sand castings compared to large-section, water-cooled, DC cast slabs.

Metallurgically speaking, rapid solidification rates improve the alloys’ microstructures and mechanical properties by fostering finer grains. However, achieving these rates and a uniform microstructure for a large slab of 254mm x 700mm x 2,000mm is especially challenging.

Various successful sand-cast magnesium alloys were considered for large slab DC casting, with some not achieving optimum results. For example, magnesium-aluminium-manganese (AZ91) is sensitive to the solidification rate to achieve an acceptable grain size and uniform properties.

Likewise, magnesium-zinc-rare-earth-zirconium (Elektron RZ5) contains a powerful grain refiner in zirconium, which improves the grain size uniformity and reduces dependency on the solidification rate, but the material suffers from segregation and responds poorly to heat treatment when DC cast.

Meanwhile, magnesium-neodymium-gadolinium-zinc-zirconium (Elektron 21) was designed as a magnesium sand-cast alloy. It benefits from zirconium grain refinement – derived from Zirmax hardener – and is designed as a fully heat-treatable (solution treat and age) alloy. This offers the prospect of a more uniform, fine-grained cast microstructure (typically much less than 100μm), with controlled strengthening precipitation post-casting.

Elektron 21, a later-generation alloy, meets the essential requirements of resistance to general corrosion and flammability.

It was selected for development as a DC cast alloy. LMT uses advanced casting modelling for both solidification and stress analysis to complement practical casting know-how, reducing casting trials and improving development productivity.

Upon successful production of a large Elektron 21 DC cast slab (254mm x 700mm x 2,000mm), and round billet (Día 225mm x 2,000mm), the heat treatment of the cast structure was optimised to achieve the desired microstructure and precipitation strengthening throughout the slab section.

To standard

Ensuring uniformity and consistency of the DC cast material is crucial for comparison with a sand-cast one.

Extensive data, from numerous slabs and heat treatment batches, was rigorously analysed by LMT and independently by Batelle in the USA. These analyses resulted in SAE and ASTM specifications, including AMS4431 – used for aerospace applications.

The thorough data assessment led the Elektron 21 DC cast slab to be included in the demanding SAE Metallic Materials Properties Development and Standardisation (MMPDS) handbook – the primary source of statistically-based, design-allowable properties for metallic materials for commercial and military aerospace applications.

Material quality verification used NDT methods such as ultrasonic inspection, and revealed that the slab meets AMS2154A Class AA criteria. National Aerospace and Defense Contractors Accreditation Programme (NADCAP) facility-approved radiography, which complies with AMS2175A Grade B standards, further assures the material’s properties and quality before machining.

Importantly, the minimum property requirements for the DC cast slab are identical to the AMS sand-cast specification for the same alloy, achieving a key technical design output.

Streamlining supply

The benefits for OEMs are two-fold. Firstly, the DC slab route streamlines the foundry supply chain by enabling rapid manufacturing through existing machine-from-solid technology. Secondly, it offers a chance to rapidly prototype new designs, ensuring that the machined-from-solid component aligns with the same chemistry and mechanical properties as a sand-cast component. This flexibility allows for either manufacturing route to be used for serial production.

The DC cast Elektron 21 in large round billet and rectangular slab finds applications in the latest engines, transmissions, structures, avionics, satellite, and electric aircraft or electric vertical take-off and landing applications, due to its desirable properties.

Moreover, electrification and hybridisation of aircraft poses challenges to payload/weight reduction, directly corresponding to battery discharge. This necessitates lighter, stronger and safer structural materials, making magnesium alloys highly desirable.