Microbes to harness mine tailings

A technique that uses microbes to recover metals from mining waste and store carbon in the tailings has been developed by researchers in Canada.

The researchers suggest microbial mineral carbonation could offset more than 30% of a mine site’s annual greenhouse gas emissions if applied to an entire mine.

Co-author Professor Ian Power of Trent University explains, 'Ore processing is not 100% efficient, meaning that mine wastes, e.g., tailings, often contain valuable minerals left over from ore processing. The amount depends on the initial grade of the deposit, recovery and how much ore is being processed. The point being these wastes do have value and are sometimes reprocessed. There are microbial processes that can help liberate these critical minerals while at the same time aiding in CO₂ sequestration.'

He continues, 'Certain microbes can produce inorganic and organic acids that can leach tailings. One classic example is bioleaching of gold ore using iron and sulphur oxidising bacteria – this is done as a heap leaching process.'

In addition to improving resource recovery, he says, 'Microbial processes can lead to the formation of carbonate minerals that bind carbon within a crystal structure, in other words, microbially mediated CO₂ mineralisation. Carbonate minerals are a long-term stable sink for CO₂, the best means of storing this greenhouse gas'.

This process, he says, is much faster than natural biogeochemical weathering processes, whereby 'mineral dissolution releases magnesium and calcium, which can then combine with dissolved inorganic carbon, sequestering it as a stable carbonate mineral. Because mineral dissolution is often the rate-limiting step for CO₂ mineralisation, it is essential that we accelerate mineral dissolution, and there are some microbes that are able to do so'.

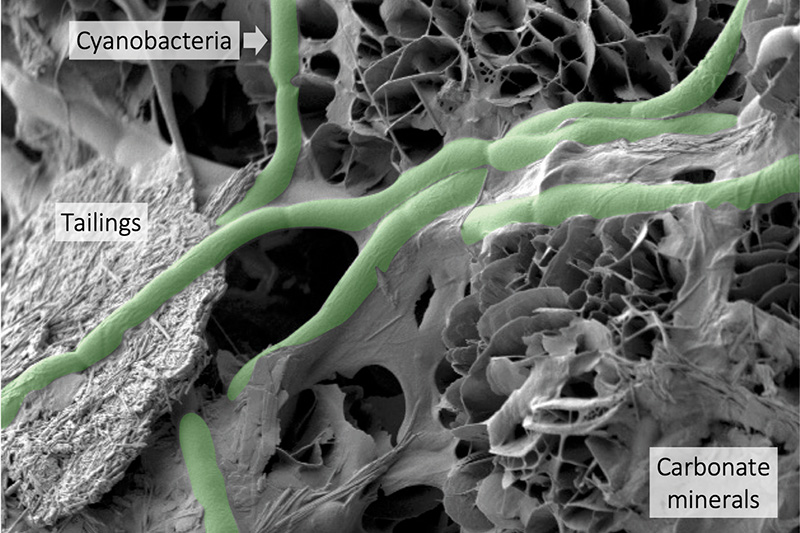

The team’s paper on Microbially mediated carbon dioxide removal for sustainable mining discusses how 'microbes, including cyanobacteria, ureolytic bacteria and sulfate-reducing bacteria accelerate carbonate mineral precipitation reactions. Microbes are often found forming carbonate mineral cements in legacy alkaline tailings'.

The paper in Plos Biology reveals how a recent trial on mine wastes from a diamond mine demonstrates that cyanobacteria contributes to both mineral weathering and subsequent microbial mineral carbonation. 'Even low rates of microbial mineral carbonation and associated biomass production using cyanobacteria could offset 34% of annual greenhouse gas emissions if this process were applied to the entire mine,' it reads.

Power adds, 'Electrification of mine operations is a crucial approach [in reducing carbon footprints] but there will likely be some emissions that are difficult to completely eliminate

'Certain mines produce more than enough mine waste to completely offset their emissions, meaning there is tremendous capacity. How much can be offset depends on the specific scenario and application of the microbial processes.' He says, 'These processes are passive and would likely require little energy input as the microbes are doing the work for us.'

Co-author Dr Jenine McCutcheon, of the University of Waterloo, expands, 'I can’t provide a number in terms of the difference in carbonation speed, but in a previous publication of mine, we demonstrated that microbial mineral carbonation of leached tailings was five times more effective than the abiotic equivalent on a per unit area basis, and if you include the amount of carbon stored in the associated cyanobacteria biomass, that number increases to 17.7 times more carbon storage than the abiotic equivalent.'

An additional benefit is that the risk of residual metals entering local waterways from tailings is also reduced, the team suggests. Power adds, 'These processes would be implemented at a mine site within an enclosed system, and so there is no concern of contaminating the environment outside the mine.'

The team has conducted laboratory and small-scale field experiments and are advocating scaling to pilot projects at mine sites. They believe industry engagement is critical to move this technology towards large-scale deployment.

Ultimately, 'there are many factors that will play into how much CO₂ mineralisation can be accelerated…In our article, we advocate for larger-scale field experiments (100-1,000t) at mine sites to help refine rates and reduce uncertainties', comments Powers.