Magnetic nanopowder for 6G technology

Material scientists have found a speedy method for producing epsilon iron oxide and demonstrated its promise for next-generation communications devices.

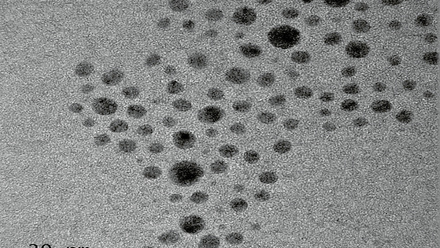

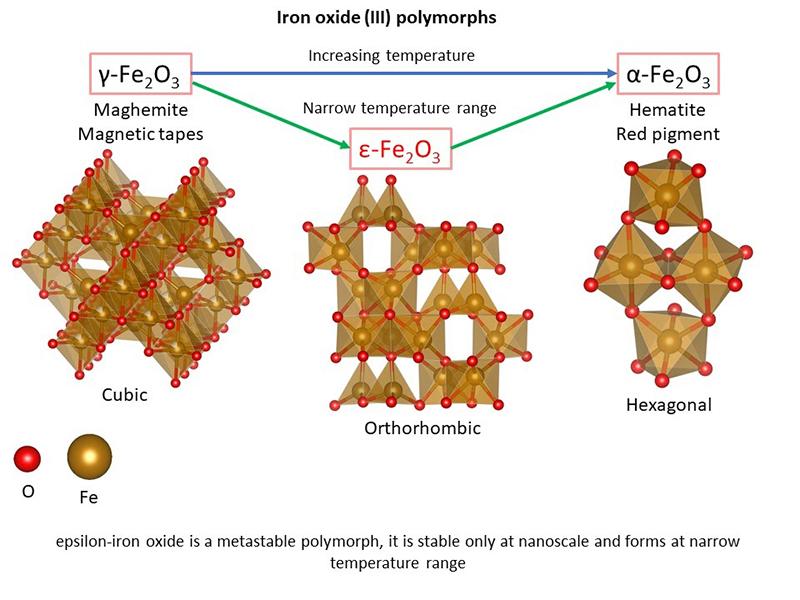

Epsilon iron oxide is an extremely rare and difficult form of iron oxide to obtain. Currently, it is produced in very small quantities, with the process itself taking up to a month.

Russian scientists have developed a method for accelerated synthesis in a day with increased quantity of the resulting product.

‘Although the epsilon-iron oxide phase was obtained in pure form relatively long ago, in 2004, it still has not found industrial application due to the complexity of its synthesis, for example as a medium for magnetic - recording. We have managed to simplify the technology considerably,’ says Evgeny Gorbachev, a PhD student in the Department of Materials Sciences at Moscow State University and primary author of the work.

The key to successful application of materials with record-breaking characteristics is research into their fundamental physical properties. Without in-depth study, the material may be undeservedly forgotten for many years, as has happened more than once in the history of science. It was the tandem of materials scientists at Moscow State University, who synthesised the compound, and physicists at MIPT, who studied it in detail, that made the development a success.

The material (ε-Fe2O3) has outstanding magnetic properties that make it one of the most coveted materials for communication devices and for durable magnetic recording. This iron oxide modification has an extremely high coercive force (the ability of the material to resist an external magnetic field). The strength reaches 20 kOe at room temperature, which is comparable to the parameters of magnets based on expensive rare-earth elements.

Furthermore, the material absorbs electromagnetic radiation in the sub-terahertz frequency range (100-300 GHz) through the effect of natural ferromagnetic resonance. The frequency of such resonance is one of the criteria for the use of materials in wireless communications devices - the 4G standard uses megahertz and 5G uses tens of gigahertz. There are plans to use the sub-terahertz range as a working range in the sixth generation (6G) wireless technology, which is being prepared for active introduction in the early 2030s. The material is suitable for making converting units or absorber circuits at these frequencies.

The work was published in the Journal of Materials Chemistry C.