Machine learning transforms iron superconducting magnets

The strongest, iron-based, superconducting magnet has been made using machine learning (ML), reports a British-Japanese collaboration.

The magnet could enable smaller and cheaper MRI machines in healthcare and advances in electrified transport - according to engineers at King’s College London, UK, who collaborated with the Tokyo University of Agriculture and Technology, the Japan Science and Technology Agency, the National Institute for Materials Science and Kyushu University.

The team says their magnet is three times stronger than current iron-based superconducting magnets.

Superconducting magnets produce very strong, stable magnetic fields without using lots of power – vital for MRI, electric aircraft and nuclear fusion. Current versions are primarily large coils of superconducting niobium-tin alloy wire, with their large size limiting usage, note the researchers.

Dr Mark Ainslie at King’s and Professor Akiyasu Yamamoto at the Tokyo University of Agriculture and Technology note that copper-based versions are also limited by high materials prices and a long fabrication time. They explain that while there are hundreds of superconducting materials, only a few can be made suitable for engineering applications. This is either in bulk form for a quasi-permanent magnet or wire form.

As a magnet that does not lose its magnetism once magnetised, using it in bulk form can result in a smaller footprint in comparison to heavier coils of wire.

As iron-based superconductors are high-temperature they do not need cooling with liquid helium like low-temperature superconductors, says the team. They also have minimal electromagnetic anisotropy and an exceptionally high critical magnetic field – above 50 tesla.

They believe these magnets are an excellent alternative to technologies that rely on conventional niobium-based superconducting magnets, such as particle accelerators, MRI scanners and MAGLEV trains.

The machine learning developed in Japan – BOXVIA – can spot patterns during production and fine-tune parameters such as heat and time to optimise design.

Conventionally, it takes months to create a magnet and test the properties to optimise it for different scenarios, while this software shortens the timeframe drastically, reports the team.

'We focused on enhancing the critical current density of the material by integrating Bayesian optimisation, which empowers data-driven experiments even when operating with limited prior data. Our approach is based on a collaborative framework, initially designing a researcher-driven process that ensures the simultaneous accumulation of data to promote a data-driven process,' says Ainslie.

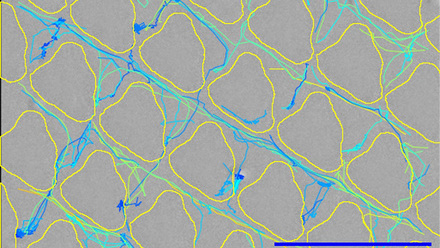

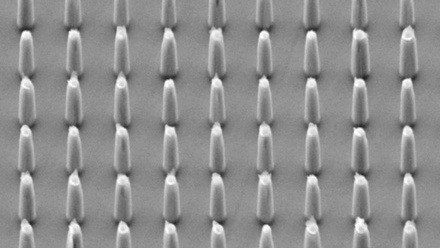

As a result, they have produced two 30mm-diameter, disc-shaped, bulk samples of potassium-doped barium iron arsenide. These were synthesised using mechanically alloyed precursors, generated through high-energy milling using a planetary ball-mill, and consolidated using spark plasma sintering.

After applying and removing a background magnetic field, the team says the magnets retain a 2.83 tesla field

as a quasi-permanent magnet – which they say is around 2.7 times more than the previous record.

Ainslie and Yakamoto note the best neodymium-based permanent magnets are limited to fields of about 1-1.5 tesla.

Decay rates are reported under 0.1ppm/h – the level of temporal stability needed for MRI scanners.

'These iron-based superconductors are polycrystalline materials and can be fabricated by common industrial processing techniques,' remark Ainslie and Yakamoto. 'Avoiding some of the difficulties when manufacturing copper-based, high-temperature superconductors – iron-based bulks can be made with larger diameters and superior uniformity, taking several hours, compared to weeks for copper-based.'

The machine-learning-developed magnets also offer a wider variety of iron-based crystals instead of a uniform structure.

'While these trials are certainly impressive and a leap forward from a materials science perspective, there are still some key steps to develop an industrial product,' they conclude. 'This includes crycooler and practical magnetisation system design, bespoke for a particular application.'