Laser welding tube finning for stronger pipes

Russian scientists have manufactured finned tubes using a laser to weld ribs with a continuous seam onto pipes using metal melting.

They claim this offers a cheaper, more energy efficient and stronger product for domestic and industrial use.

Ribbed tubes are used in chemical, petrochemical and refining industries for condensers, gas heaters and gas coolers; in compressor and refrigerating units and oil coolers; in the nuclear industry for coolers, dryers and steam heaters; and in air conditioning and heating systems.

The team at Ural Federal University has created the tube finning after developing a similar panel finning technology for high-temperature plate heat exchangers. Unlike many Russian manufacturers who use spiral finning – fins welded on analogues crosswise – the researchers have installed the fins along the tube. According to Project Manager Alexander Volkov, this process is suitable for heat exchangers using gas media.

‘With the spiral finning of pipes, the fins are located across the flow. The gas flow, when it passes through the heat exchanger, bends around the places between the ribs, and vortices are formed,’ he explains. ‘With the longitudinal ribbing, the flow resistance is minimal, and the flow passes between the ribs. Turbulence is eliminated and the effective contact area is increased.’

Historically, welding fins along the tube has been a difficult, expensive and time-consuming process, the team says. They explain that manufacturers in China and Italy use spot condenser welding, a process that involves rolling a roller and tacking the rib with points.

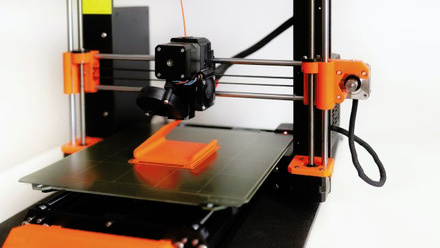

The Russian team, however, has applied the principles from panel finning, using laser welding to manually install the fins along the tube. After perfecting the technology, the scientists have automated the process and used a robotic laser to install up to 9m of fins per minute. They say any metal can be welded to a pipe of any diameter.

Volkov suggests that the advantage of using laser welding is that a homogeneous crystal lattice is formed at the point where the pipe and the rib are welded, improving heat transfer and the material’s strength.

‘The use of laser welding allows us to place the ribs with a pitch of 5mm compared to capacitor welding from 10mm,’ he says. ‘When calculating a heat exchanger, this allows us to reduce the dimensions of the pipe while maintaining the useful area and reducing the metal consumption.’

The team has had to overcome technical issues. During the process of manufacturing a prototype pipe, seven different versions of the laser welding technology were used and had to be corrected before the prototype was created in 20 days.

The process also involved a large number of manual operations which increased the likelihood for errors. As Volkov explains, a slight displacement during the installation of the rib resulted in an inferior product and the entire process had to be redone.

Another challenge was to select the correct material. Initially, the team used one steel grade for the test specimen. After releasing a finished batch of pipes, they then substituted the test material analogue with a material that transferred heat better. Although this created deformed ribs after welding, Volkov says the production time was more than halved.

All pipes undergo thorough testing during the manufacturing process, he adds. This includes checking the material’s quality, ensuring the quality control of manufactured ribs before their transfer to welding, and a final test after the laser welding has been completed. ‘Pipe testing involves installing a finned pipe in heat exchange equipment and installing it onsite,’ he explains. ‘The recuperator checks and the calculated characteristics are compared with the actual values obtained which is a lengthy process. The control is carried out throughout the heat exchange equipment’s entire service life.’

A patent has been applied for and the first order – the manual welding of 9,200 fins onto 20 pipes – was completed in three months. The team is increasing its production capacity and takes delivery of a robotic laser welding system in December, enabling production on an industrial scale.