Imperfections enhance steel alloys

US scientists are exploiting the imperfections found in high-entropy steel alloys to design strong, albeit ductile, metastable alloys that could be used for construction projects to withstand earthquakes.

The researchers claim that the innovative design features overcome the well-known trade-off between strength and ductility, ideal for building naval ships, for use in the aerospace and automotive industries, in nuclear energy and, potentially, additive manufacturing.

The team – at the University of Pittsburgh Swanson School of Engineering and the Illinois Institute of Technology (IIT) – says it has explored two mechanisms for metastability engineering to create strong, ductile, high-entropy alloys – transformation-induced plasticity (TRIP) and twinned-induced plasticity (TWIP).

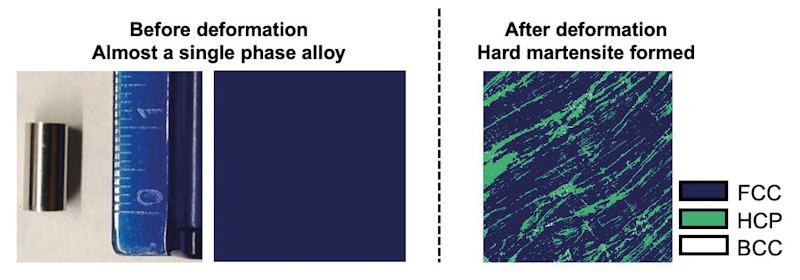

Both use changes in the alloy’s microstructure when deformation is applied and cause defects in the material that can be exploited to enhance strength and ductility simultaneously.

Xin Wang, a PhD student in the Pittsburgh team, explains that the researchers first applied CALculation of PHAse Diagrams (CALPHAD) modelling to screen more than 100,000 compositions to select alloys that demonstrate the face-centred cubic (FCC) single phase, or FCC with hexagonal close-packed (HCP) dual phases.

'We used Thermo-Calc software to estimate the stability of different phases by screening the Gibbs energy of the FCC and HCP phases at room temperature and homogenisation treatment temperature,' he says.

'We want to understand the unstable microstructure so we can predict the instability, and then we can use the defects to further increase strength and elongation.'

Wei Xiong, Associate Professor of Mechanical Engineering and Materials Science at Pittsburgh, adds that they have selected alloys with a single FCC phase at homogenisation temperature to ensure that no precipitations will form after heat treatment to change the matrix composition.

They have also selected alloys that demonstrate a small Gibbs-free energy difference between FCC and HCP at room temperature to ensure the FCC is unstable and more likely to have TRIP or TWIP.

The smaller the energy of the HCP phases, compared with the FCC phases, Wang adds, the easier it is to stack more faults – a type of 2D defect layer – and the greater likelihood there is to transform FCC into HCP during the deformation process.

Next, the researchers undertake a kernel density plot to select seven alloys that can demonstrate varying FCC stability. Using density-functional theory (DFT) methods, the Pittsburgh and IIT team then can calculate the energy associated with the transformation of stacking faults into HCP structure and twins, he says.

'Unlike previous work that calculated intrinsic stable stacking fault energy (ISFE) to predict if TRIP and TWIP will happen, we proposed to calculate the unstable fault energy associated with twin and HCP formation, which is unstable twin fault energy and unstable martensite (HCP) fault energy,' he explains.

'If unstable twin fault energy is lower, then TWIP is prone to happen. If unstable martensite fault energy is lower, TRIP is the dominant deformation mechanism.'

Xiong says the Pittsburgh team prepares samples and characterises them using electron backscatter diffraction and transmission electron microscopy to validate their findings.

As part of the research, the university has collaborated with Professor Wei Chen at IIT, who performs quantum mechanical calculations to understand the fine atomistic level of the effects.

The significance of this approach is that the researchers can predict the TRIP/TWIP behaviour of the alloys without the need for experiments.

Xiong adds that the team’s approach focuses on understanding the difference between unstable defect energy – such as martensite, twinning and stacking faults – rather than directly relying on a single stacking fault energy, which is widely used in designing steel.

The plan is to design TRIP/TWIP alloys with strengthening particles and hierarchical structures to further improve their properties.