High stiffness meets high-damping properties

A novel composite material reportedly combines two previously incompatible properties – high stiffness and high damping capacity.

Researchers at ETH Zurich, Switzerland, have deployed stiff materials like silicon and glass plates connected by ultra-thin, rubber-like layers formed by crosslinking a polydimethylsiloxane (PDMS) mixture.

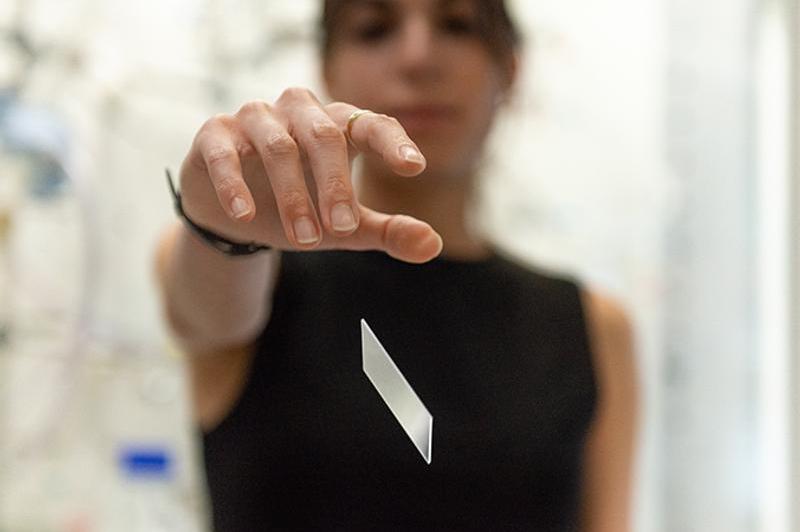

The first prototypes use silicon and glass plates that are 0.2-0.3mm thick connected by rubber-like layers with a thickness of a few hundred nanometres.

Computer models have calculated that the rubber-like layers need to be less than 1% of the total volume, while the rigid layers constitute at least 99%.

'There is very little of a damping effect if the polymer layer is too thin. If it is too thick, the material is not stiff enough,' explains researcher Ioanna Tsimouri.

The composites have five layers in total – three stiff and two rubber-like. The stiff layers are made of a glass commonly used in smartphones, while the polymer comes from commercially available PDMS-based polymers with chemically reactive sites.

Adding a catalyst combines these sites to form a polymer network, i.e. a rubber-like polymer to connect the stiff plates like a two-component sealing.

They improved adhesion through plasma treatment on the glass and silicon surfaces before depositing the PDMS and catalyst.

Tsimouri used three types of PDMS polymer chains – backbone chains with a few functional groups to connect with other chains, cross-linking chains with two functional groups at both ends of the chain, and dangling chains with only one functional group.

They have used the catalyst cis-[PtCl2(styrene)2] at 120ppm compared to the total mass of PDMS polymers.

The team has tested the frequency- and temperature-dependent mechanical properties of the laminates using a three-point bending test.

Tsimouri also dropped the laminate plates from 25cm to compare the acoustic and mechanical damping to a plate of pure glass. The laminate plates showed 'excellent' damping properties and stability, hitting the table more quietly without bouncing. There was no delamination after 25 repeated tests.

As the polymers react rapidly after adding a catalyst, creating the desired thickness has been a challenge, says Tsimouri. She developed a process to apply the solutions to glass or silicon discs at the required thickness. In addition, she had to produce cross-sections and examine them under a scanning electron microscope.

The laminate is also said to be temperature-resistant, enduring a range of temperatures without losing its damping ability. It only becomes glassy and loses that ability at temperatures below -125°C.

The team says the laminate could be used in window glass, machine housing, car parts, aerospace or sensor technology, where there is a desire to limit the impact of vibration and noise.

They suggest the glass and silicon can be recycled easily, and when melted down, the small amounts of polymer would decompose and therefore not affect the recycling process.