Graphene enabled infrared textiles

Professor Coskun Kocabas at the National Graphene Institute, Manchester, UK, makes the case for how graphene could transform the wearables market.

The wearable technologies sector is rapidly growing with a market value of over US$50bln. Among many alternatives, textiles provide a natural host environment for emerging wearable devices. The integration of devices on textiles is, however, challenging as conventional wafer-based microfabrication methods require adaptations into soft and nonplanar forms. Conversely, it enables work with traditional textile materials and methods and takes advantage of the ubiquity of these materials and well-established manufacturing infrastructure.

The ideal body

Wearable infrared applications are especially appealing as the human body is a near-ideal thermal emitter, which makes it visible in thermal imaging systems. The body emits mainly in the infrared wavelengths and is capable of losing up to 2,000kcal in a day through thermal emission. Therefore, controlling thermal emission from textiles has significance for key applications such as thermal management, adaptive camouflage and optical communication. However, techniques applied to do this using humidity or thermal triggering need to be significantly improved by conceiving a more convenient method. Specifically, electro-optical control can enable integration with other wearable technologies and can provide dynamic, fast and on-demand modulation. To counter this challenge, we have leveraged the electrically tuneable properties of graphene. Graphene and other 2D materials provide new and exciting opportunities for functional textiles and we have been investigating graphene as an adaptive optical platform operating from the visible to microwave wavelengths.

Ionic motion

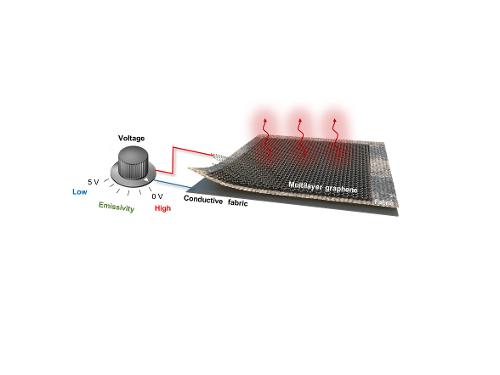

By merging the chemical vapour deposition (CVD)-grown graphene with textiles, an optical textile technology is being developed. The devices consist of laminated layers of polyethylene, multilayer graphene (MLG), a fabric separator layer and conductive fabric. An ionic liquid electrolyte is applied to the textile substrate at the final stage. The thin polyethylene film functions as an infrared-transparent protective layer and a support substrate when laminated on the MLG. The textile acts as both the separator and ionic conductive layer, allowing ionic motion when a voltage difference is applied between the MLG and the back electrode.

The fabrication method is compatible with a variety of natural and synthetic textile materials including woven cotton, polyester, elastane, silk, wool and non-woven high-density polyethylene. For the back electrode, alternatives are numerous including silver-based conductive textiles, stainless steel mesh, sputtered gold, graphene and reduced graphene oxide. Patterning the back electrode can increase functionality by confining modulation of the optical properties on a continuous top MLG. An array of patterned back electrodes have been formed with photolithography followed by metallisation and lift-off process.

Voltage variation

The devices’ working principal is based on reversible modulation of the infrared properties of the top graphene layer using electrical signals. In the initial stage, the top graphene layer has high thermal emission. When a sufficient voltage difference is applied (>2.5V) between the graphene and back electrode, thermal emission from the graphene layer is suppressed. The operation can easily be monitored with a long-wave infrared camera that renders apparent temperatures of surfaces by sensing the emitted thermal radiation.

The devices show a very fast response. They change their thermal appearance in less than five seconds after applying the electrical signal. Reversing the voltage difference to 0V recovers the initial state. Thus, the devices can be cycled steadily between high and low thermal emissivity states with repeated electrical signals. They also operate over a broad spectral range from short (0.9-1µm) to long (8-13µm) wavelength range. However, modulation in the visible spectrum is limited.

Stretching the possibilities

The developed fabrication scheme allows stretchable textiles to accommodate the natural deformation and drapeability of textiles in action. This is achieved by structuring the graphene layer into periodic, wavelike geometries on the textile surface, providing forms that can be stretched and compressed without damaging the graphene layer.

Graphene layers are laminated on the fully stretched elastane knitted fabric, allowing buckling when the fabric is relaxed and adhering to the fabric in both conditions. Modulation of thermal emission can be achieved in both relaxed and stretched conditions.

Further flexibility is demonstrated by scaling the devices down to yarn level. This enables a finer spatial resolution as well as forming an active textile surface by interlacing. The yarns have a conductive core and are covered with graphene layers. The devices are finished by applying ionic liquid to the cladding layer. Different from the 2D textile devices, the yarn approach emits infrared radiation in all radial directions, allowing the technology to be observed from any angle.

Talking fabrics

Due to natural body temperature, the human body radiates ~100W of infrared light in ambient conditions. This peaks within the atmospheric transmission window, enabling long-distance propagation of the emitted infrared light and, therefore, communication in the infrared by modifying the human body thermal emission with a textile device.

By way of example, a t-shirt has been fabricated to electrically modulate thermal emission from the human body (see images on previous page). Fabricated from 100% cotton and operated by a battery-powered micro-controller, the device communicates the letters N, G and I in Morse code invisible to the naked eye but detectable only by a thermal camera.

The use of a micro-controller further allows more sophisticated circuitry to be fabricated on textiles, in turn enabling more secure communication protocols. This demonstration emphasises the technology’s adaptability to an everyday apparel in a realistic environment, the use of body temperature for the operation and the portability through the use of a small-scale and light-weight controller and power source.

The use of small electrical signals to modulate infrared emissivity is a significant advantage over the alternatives, requiring low voltage and energy. Therefore, a compact battery with 1,000mAh capacity can turn on a t-shirt size (~1m2) device ~180 times. What is more, the average standby power is virtually zero enabling hours or days of operation depending on the switching frequency. The low-voltage and low-power operation highly enhances the portability and integrability with a miniature controller and power supply. In contrast, the alternative method of directly heating a surface to control thermal emission necessitates ~100W for the same area. The same compact battery can only power such a device for only ~100 seconds.

Beyond textiles

Adaptive thermal management of the human body reduces the need to cool/heat large volumes of air, thus saving energy. The developed textile technology, integrated with temperature sensors, can quickly adapt its thermal emission to maintain its temperature at a desired level.

The application can also easily extend to larger objects such as buildings and cars owing to the ease of large-area fabrication and low-power operation, as well as find its way to satellites and spacecraft which completely rely on control of thermal emission for dynamic thermal management. Keeping the internal satellite temperature in a specific window is crucial for the operation, requiring a balance of generated heat with the energy loss. Therefore, a satellite’s thermal emission must quickly adapt to the rapidly changing generated heat. This technology can rise to the challenge by providing a large dynamic thermal emission range, high-speed, low power and high durability in the harsh outer space environment.

Although the demonstrations focus on the long-wave infrared regime, the study provides a framework for graphene-enabled adaptive optical textiles. The developed methods for fabrication and transfer of graphene are compatible with the textile industry and large-area processing, allowing easy integration with well-established textile infrastructure. The successful demonstration on different forms of textile can enable new technologies operating in the infrared and other regions of the electromagnetic spectrum.