Glowing glass fends off biofilm in marine environments

A UV ray-emitting glass could reduce 98% of biofilm growing on surfaces underwater, according to its inventors in the US.

University of Massachusetts Amherst engineers have created an alternative to chemical methods to treat the slimy layers of microorganisms that grow on wet surfaces.

This would be a boon to the US Navy, which estimates biofilms cost its fleet US$180-260mln annually.

With US Office of Naval funding, the engineers have created a biofilm-resistant glass using UVC radiation – the shortest wavelength (100-280nm) that is the most effective at disinfecting.

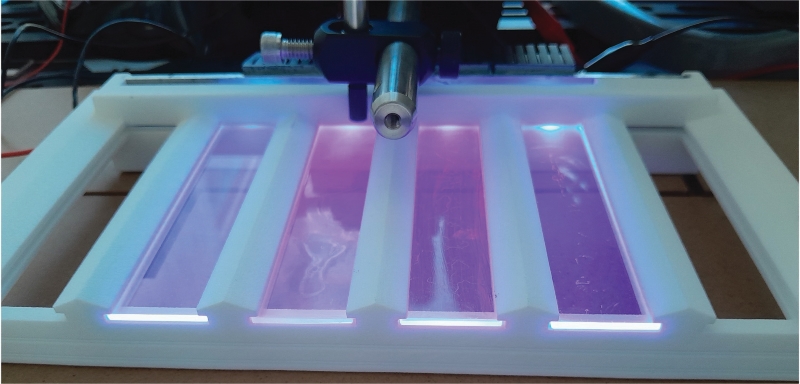

The lab has already demonstrated that a UV side-emitting optical fibre can distribute UVC radiation in small channels, like in medical equipment, home devices and water storage/distribution systems, to inactivate pathogenic organisms and prevent bacteria growth on surfaces.

The paper – UV emitting glass: A promising strategy for biofilm inhibition on transparent surfaces published in Biofilm – describes how UV transparent quartz slides are cleaned with acetone and sonicated, before scattered silica nanoparticles are applied using electrostatic deposition before drying.

A semi-print screen technique coats the slide with a fluoropolymer that has an amorphous structure and over 95% transparency at 1mm across a wide spectral range. It acts as a cladding, protects the glass core and fixates the nanoparticles close to the substrate. After sonication, the polymer is dragged along the exposed glass slide with the round edge of a razor blade and dried at room temperature overnight.

However, UV light does not distribute evenly on underwater surfaces. The light becomes weaker as it moves away from the source, making it difficult to cover large surface areas. The UV waves are also disrupted by how murky the surrounding water is. Uneven distribution of the UV light gives biofilm-forming microorganisms a foothold and leaves the whole surface vulnerable.

The silica-nanoparticle coating on the glass scatters the light from inside to the outside, enabling an even glow. The silica does not absorb the UV rays, and the waves continue to bounce off the nanoparticles and through the glass interior.

'Contrary to the external UV irradiation technique, UV-emitting glass inhibits biofilm formation directly at the surface of interest – the surface itself serves as a UVC source,' says postdoctoral research associate Leila Alidokht.

Assistant Professor Mariana Lanzarini-Lopes explains that the optimum concentration of silica is 26.5μg/cm² for optimal scattering of UV light away from the waveguide.

After submerging a 2 x 10cm glass in the waters of Port Canaveral, Florida, for 20 days, the team has found it reduces visible biofilm growth by 98% compared to untreated glass.

They have measured the UV-emission intensity (observed glow) using a UV spectroradiometer.

Of the impact on other properties, Lopes says, 'Much of our work so far is ensuring there is no impact on the visibility through a transparent surface. We will, however, be running multi-month submersions and testing for longevity/durability/strength of the material compared to its unmodified version.'

The polymer is the main cost driver, Lopes notes. Optical Waters is licensing the technology and working to drive down the cost of each component and overall manufacturing.

The group has begun testing on larger 10cm units.

'We foresee this as being the starting point of innovation in UV biofilm prevention for various surfaces and materials,' Lopes concludes.