Going strong - creating fuel cells with cobalt-based catalysts

Increased strength, durability and improved reaction activity are proclaimed as the deliverable results of a new fuel cell catalyst using cobalt.

Researchers from Pacific Northwest National Laboratory (PNNL), USA, claim this is the highest activity in fuel cells reported for non-iron, platinum-group-metal-free catalysts to date.

The team expresses how using cobalt interspersed with nitrogen and carbon (Co-N-C) could be an effective transition metal, providing an alternative to platinum for the necessary chemical reaction in fuel cells at around half the costs.

‘We knew that the configuration of cobalt with nitrogen and carbon was key to how effectively the catalyst reacts and that the active site density was critically important for performance,’ says Yuyan Shao, Materials Scientist at PNNL, who led the study. ‘Our goal was to really improve the reaction activity of cobalt-based catalysts.’

The team developed protective fences around the cobalt atoms by immobilising the cobalt-based molecules in the micropores of zeolitic imidazolate frameworks. This decreases the cobalt atoms’ mobility and prevents them from clustering. They then proceeded to convert the atoms to catalytically active sites within the framework using high-temperature pyrolysis.

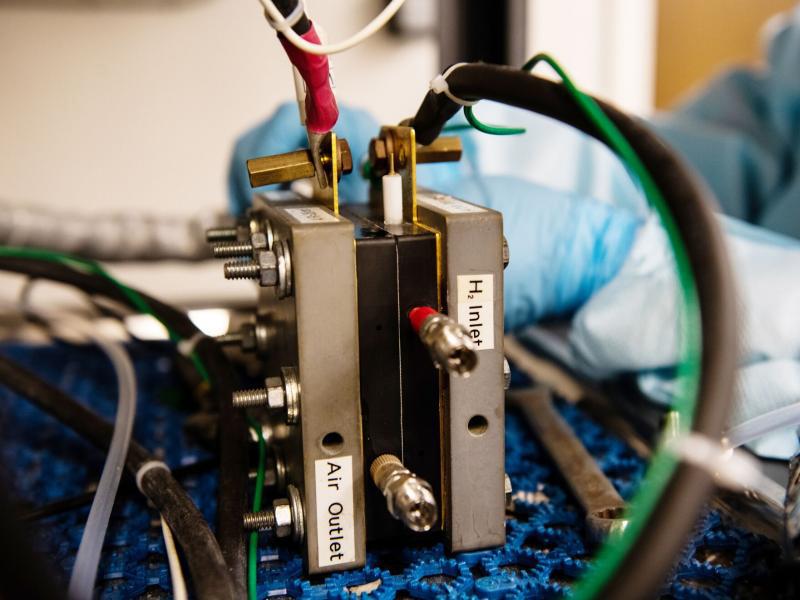

The study, Performance enhancement and degradation mechanism identification of a single-atom, published in Nature Catalysis, states, ‘The Co-N-C catalyst achieved a current density of 0.022Acm-2 at 0.9V (internal resistance-compensated voltage) and peak power density of 0.64Wcm-2 in 1.0bar H₂/0₂ fuel cells, higher than that of non-iron platinum-group-metal-free catalysts reported in the literature.’

The researchers claim they have discovered, for the first time, significant differences in demetallation, where metal ions are leached out of the catalyst to then lose activity. They have also found that oxygen radicals from hydrogen peroxide, a by-product of oxygen reduction in fuel cells, attack the catalysts and cause performance loss.

The paper reads, ‘Importantly, we identified two main degradation mechanisms for metal (M)-N-C catalysts – catalyst oxidation by radicals and active-site demetallation. The enhanced durability of Co-N-C relative to Fe-N-C is attributed to the lower activity of Co ions for Fenton reactions that produce radicals from the main oxygen reduction reaction by-product, H2O2, and the significantly enhanced resistance to demetallation of Co-N-C.’

In addition, the team has compared its findings with another potential transition metal, iron, which is considered a promising alternative to platinum but can quickly degrade in the acidic proton exchange membrane fuel cell environment. The results reveal cobalt to be four times more durable than iron – despite previous studies that have found cobalt to be less attractive than iron-based catalysts.

The team suggests that the process for synthesis is scalable and its application is also similar to other catalysts, but its durability needs significant improvement before commercialisation is achievable.