Electrified charcoal sponge soaks up CO2 from air

A form of charged charcoal could offer a low-cost, energy-efficient method to capture CO2 from the air.

The charcoal ‘sponge’, usually used in household water filters, is being charged with ions that form reversible bonds with CO₂. Once charged, researchers from the University of Cambridge, UK, report that it is capable of capturing CO₂ directly from air and requires much lower temperatures to remove the captured CO₂, which is to be stored.

Current approaches are expensive, require high temperatures and the use of natural gas, as well as lacking stability, according to the Cambridge team.

First author Dr Huaiguang Li, who now works at the Chinese University of Hong Kong in Shenzhen, says, 'Most materials currently used for CO₂ capture from air need to be heated to temperatures as high as 900°C. However, the charged charcoal sponges only require heating to 90-100°C to reverse the hydroxide-CO₂ bonds.'

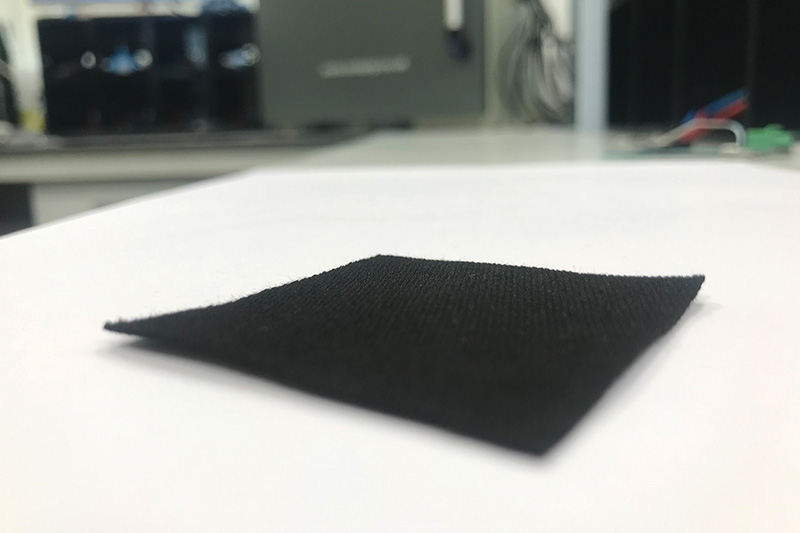

The team has used a battery-like charging process to accumulate hydroxide ions in the pores of an 'inexpensive' activated charcoal cloth.

Li expands, 'In this process, the cloth essentially acts like an electrode in a battery, and hydroxide ions accumulate in the tiny pores of the charcoal. The charged sorbent rapidly captures carbon dioxide from the air by forming (bi-) carbonate.

'In contrast to conventional bulk carbonates, the desorption process of charged adsorbents does not need to overcome lattice energy barriers and can, therefore, be completed at relatively low temperatures (90-100°C).

At the same time, due to the adsorbent’s suitable electrical and thermal conductivity, in situ joule heating desorption can be carried out directly using renewable energy sources, which significantly improves energy efficiency.'

Li adds, 'The cost of raw materials for the charged sorbent is inexpensive, which makes the CO₂ capture cost low.'

At the end of the charging process, the charcoal is removed from the ‘battery’, washed and dried.

Li believes the process is scalable, 'considering the availability and cost of raw materials, as well as the complexity of the manufacturing process, we are working now to scale-up the sorbents'.

A patent has been filed and the research is being commercialised with Cambridge Enterprise’s support.

In the future they will focus 'on increasing the quantity of carbon dioxide that can be captured, and in particular under humid conditions where our performance decreases', shares Li.

He notes that direct air capture is an essential technological pathway towards carbon neutrality. 'Carbon capture using alkaline solutions (e.g. potassium hydroxide and calcium hydroxide) as adsorbents has the significant advantages of large-adsorption capacity, high efficiency and speed.

'However, the adsorption product, carbonate, has an enormous lattice energy, which significantly increases the operating costs of carbon capture. Reducing the energy consumption of capture is the key to the research and development of high-performance adsorption materials.'