Developing the soft drinks market through innovative packaging

David Rose considers the trends and drivers behind changing pack formats alongside how the beverage industry is responding to the challenges regarding materials from consumers, pressure groups, retailers and legislation.

Soft drinks have one of the widest range of consumers for a FMCG product, from one- to one hundred-year-olds with different preferences and requirements, packaging, product and users age need to be considered. Increasingly, all are engaging with the food supply chain and have become more vocal in expressing their needs and concerns and pressuring for change.

However, to be financially viable and successful in this increasingly challenging commercial environment, all developments must demonstrate an enhancement to either the consumer or supply chain. This can be functional or added value - helping them accomplish a task more easily or differently, saving money, or both. But predicting consumer demand six months ahead is difficult enough, let alone over two or more years, so any development carries a degree of commercial risk that by the time it has been developed, validated and equipment installed, demand has changed. Even in the time taken to research and write this article, concepts were taken to pilot or delivery and new developments were announced.

In the beverage market, the focus has traditionally been on the drink itself, with the packaging being simply the means of delivery. This could be a functional drink requiring specific barrier protection or allow consumption of beverages without additional preparation, e.g. self-chilling or self-heating cans. Also, the rise of the discounter and e-commerce have required innovations in secondary and tertiary packaging to ensure the primary pack is delivered to the consumer in optimum condition.

Apart from the weather and other seasonal influences which drive annual cycles in volume sales there are number of macro trends and drivers of beverage markets influencing beverage developments. However, none of these trends should be considered in isolation and any developments will be influenced by a number of them. But in some cases, these drivers have contradicting influences which create further challenges and may result in the diversification of pack formats.

A plastic free society?

Over the past 30 years or so, due to its material properties and economical production, the PET bottle with a plastic closure has been the primary container for soft drinks and bottled waters. This, combined with the fact that the pack is designed to be visible for branding/marketing means the problems of inappropriate disposal and litter has resulted in these packs becoming the focus of consumer, pressure group and legislator concern. The 'blue planet effect' has created what has been termed ‘plastiphobia’ and driven plastics bans. This simplistic view of replacing oil-based plastics with something else, does not consider that the other options may also have environmental impact such as increased CO2 emissions, restricted supply or there may be no alternative available to meet the packaging performance requirements.

There is also a question around socioeconomics. While affluent consumers can use their wallets to move away from what they see as the irresponsible use of plastic to more sustainable products and packaging, where does this leave those less well-off who cannot afford these alternatives which often have a significant cost difference?

This current focus on plastic bottles has in turn made the PET bottle the priority for the soft drinks and bottled water manufacturers in terms of developing strategies to reduce material use, ensuring existing materials are recovered and recycled, increasing the use of recycled materials and developing sustainable alternatives.

It should be noted that weight reduction has finite limits, the bottle must still function, enabling the consumer to grip and hold it to open and use it. There is also the question of the capital investment required in the equipment to produce and pack these bottles, which is beyond the capacity of most bottlers.

These issues and the pressure to move away from ‘bad’ plastic has pushed many of the smaller beverage companies to look at some of the alternatives to PET, so called bio-plastics derived from biomass. While there are a number of different materials available, they are not a simple replacement for PET. A number of these bio-plastics have been developed but their structural properties, barriers, and differences in processing and filling often mean they are not a direct replacement and they can have a negative effect on both energy use during production and product shelf life.

The first commercially used bio-plastic was polylactic acid (PLA), a biodegradable polymer of lactic acid, produced via the fermentation of plant starch. It has similar mechanical properties to PET but has a significantly higher oxygen and carbon dioxide permeability, which limited its' use to still beverages and water which are not sensitive to oxidation. It also has a lower continuous use temperature which narrows the processing conditions for stretch/blow moulding bottles.

There are a number of other bio-based polymers which so far have not been commercialised due to cost of production or limitations in their individual properties. However, blending two complimentary bio-based polymers could result in the optimal properties for bottle production.

Polyhydroxyalkanoates (PHAs) are biodegradable polyesters produced by bacterial fermentation of sugar or lipids. A number of different monomers can be combined to produce biodegradable materials with extremely different properties, either thermoplastic or elastomeric materials, with melting points ranging from 40°C to 180°C. One of these, polyhydroxybutyrate (PHB) has mechanical and physical properties similar to PET with a high melting temperature, a high degree of crystallinity, and low permeability to oxygen, water and carbon dioxide. However, the high cost associated with production, and a melting temperature which is close to the thermal degradation temperature will require further development before it is a viable commercial option for use in beverage bottles.

Another bio-based polymer is polyethylene furanoate (PEF), produced by polymerising furandicarboxylic acid in the presence of ethylene glycol, both of which can be obtained using renewable raw materials (sugars) derived from plants or food process waste. PEF looks to be a good replacement for PET with very good barrier and structural properties. It has an oxygen barrier six times greater and a carbon dioxide barrier three times greater than PET. It also has a higher glass transition temperature, lower melting point which permits greater lightweighting as well as superior thermal stability without heat-setting so can be hot filled at about 90°C. Two commercial scale pilot plants have been installed by European companies Avantium and Stora Enso.

A third is polybutylene succinate (PBS), a biodegradable semi-crystalline aliphatic polyester synthesised from succinic acid and 1-4-butanediol, both of which can be produced from renewable feedstock such as glucose and sucrose via fermentation. PBS is a very promising biopolymer because its mechanical properties are comparable with those of high-density polyethylene and isotactic polypropylene. In comparison with PLA it is much more flexible and thus does not require plasticisers but has a lower melting point of about 115°C.

There is also poly(butylene adipate-co-terephthalate) (PBAT), a semi-aromatic, biodegradable thermoplastic co polyester synthesised from the polymer of 1.4-butanediol and adipic acid and the polymer of dimethyl terephthalate (DMT) with 1,4-butanediol. Adipic acid and 1.4-butanediol are polymerised to create their polyester (plus water). PBAT has a random structure so it does not crystallise to any significant degree, which results in a wide melting point, low elastic modulus and stiffness, but high flexibility and toughness. The high flexibility and toughness mean it is not strong and rigid so not suitable where strength and rigidity is desired but make it ideal for blending with another biodegradable polymer for bottle production.

Thermoplastic starch (TPS) is a biopolymer derived from carbohydrates such as potatoes or maize. The TPS is then blended or laminated with polymers such as polyethylene or PLA to create a biodegradable alternative made partially or entirely from renewable resources that offers the same or better characteristics than 100% polymer blends. However, while blending with other biodegradable plastics has no environmental impacts, blending with conventional plastics such as PE or PP potentially can result in microplastics, another area to which many consumers are sensitive.

But as well as bio-plastics derived from biomass, a number of companies are looking at alternative packaging formats from a range of sources such as wood fibre, seaweed and fish waste.

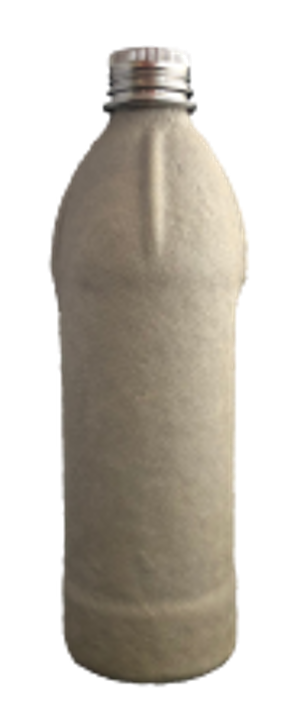

Choose Water has developed a recycled paper bottle with a bio-plastic based liner which is expected to be commercialised later this year. The composition of the liner has not been disclosed.

Meanwhile, Carlsberg has unveiled two new research prototypes of its Green Fibre Bottle. Both are made from sustainably sourced wood fibres and have an inner barrier to allow the bottles to contain beer. One prototype uses a thin recycled PET polymer film barrier and the other a l00% bio-based PEF polymer film barrier.

French packaging company, Lyspackaging has developed a bottle – VeganBottle - using sugar cane bagasse (the fibre/pulp that remains after extracting the sugar cane juice) with other plant based products (a trade secret) to produce bottles capable of holding water, beer or oil.

Lucozade have completed trials using seaweed-based bio plastics at some events. Packaged in a small pouch, made by UK company Notpla. The package is edible, biodegrades naturally in 4-6 weeks, is home compostable and is claimed not to contaminate PET recycling.

There has also been some work using waste fish products, researchers from Penn State University, USA, have investigated a polymer made from cellulose pulp from wood or cotton and chitosan, made by treating the chitin shells of shrimp and other crustaceans with an alkali. At the same time, a student at University of Sussex, UK, has developed MarinaTex made from organic fish waste and locally sourced red algae. While initially developed as a bio-based material to replace flexible plastics, there may be options to blend with other biomaterials to produce pouches or similar packs for beverages.

The potential challenges of bio-polymers have led to a number of developments of bio-based (renewable feedstock) plastics where the precursors in the manufacturing process are derived from waste biomass before conversion to conventional plastics.

Both PepsiCo and Coca-Cola have already commercialised 'plant bottles' where the mono ethylene glycol (MEG) component of the PET (around 30%) is sourced from fermentation of waste sugars.

There are now a number of companies (joint ventures) developing commercial scale process to produce para-xylene from biomass, which can then be converted by catalytic oxidation to the other component, terephthalic acid, resulting in 100% bio sourced PET which is chemically identical to oil-based PET.

There are also a number of companies who have commercialised developments of bio-sourced polyethylene (both low and high density) for use in closures, so both the bottle and closure can be claimed as bio sourced. Dow UPM BioVemo is developing a process to produce naphtha from crude tall oil, a residue of paper pulp production, then using this feedstock to produce bio-based polyethylene (PE).

However, while these bio-sourced plastics have the environmental benefit of being sourced from sustainable sources so can claim some reduction in CO2 (from the crop growing), they are chemically identical to oil based plastics so still have the same recovery and recycling issues. But being identical they do not require a separate recovery and recycling infrastructure which simplifies their introduction and use.

There are also a number of significant challenges around food safety, availability and separation and recovery to overcome if bio sourced, biodegradable or compostable plastics are to reach the mainstream.

Safe and clean

One key challenge with biomass-based polymers is the potential risk regarding contamination and food safety. Fera Science Ltd, UK, recently conducted a review on behalf of the UK Food Standards Agency examining evidence relating to potential risks and other unintended consequences of replacing oil-based plastic food packaging and other food contact materials with bio-based food contact materials. The review concluded that the biodegradability combined with manufacture from a diverse biomass resource may lead to additional sources of risk compared to traditional plastics.

For example, very limited information is available on the potential allergenicity of bio plastics or possibility of transfer of allergens to food. It also identified that limited research has been undertaken into the development of bio-based plastics derived from agri-food by-products and understanding the associated risks to the consumer. Before such polymers can be used in the food sector, information on the presence of inorganic contaminants such as heavy metals. persistent organic contaminants and natural toxins, and their capacity to transfer into food is required.

Questions remain around the capacity to replace all oil based with biosourced plastic. Suppliers must obtain the raw materials from sustainable sources and process waste, not by diverting materials from food production.

The global bioplastics production capacity is set to increase from around 2.1 million tonnes in 2019 to 2.4 million tonnes in 2024. However, the market share remains low compared to primary plastics, as more than 300 million tonnes of virgin plastic are produced every year, and this is expected to increase by some 50 million tonnes over the next five years.

The majority of the growth in bioplastics is driven by packaging using more than 53%, but other areas such as automotive, agriculture/horticulture and toys to textiles are predicted to increase their uptake.

Carbon footprints of different plastics also play a part. Bio-based plastics are produced from plants, which capture atmospheric carbon dioxide as they grow, but if they are composted, the materials are released back to the atmosphere as carbon dioxide and water. This makes the material itself carbon neutral, although manufacturing will generate some greenhouse gasses. This needs to be compared to traditional plastics when the carbon is retained through an integrated closed loop recycling system.

But comparing the carbon footprints of different plastics is not easy for an expert, let alone the general consumer who relies on the internet for most of their information. There is disagreement about the lifecycle impact of bioplastics and some research indicates bioplastics may have a more negative impact on the environment than conventional plastics due to the increased weight and different production methods. Some studies have shown that while some bioplastics reduce fossil fuel use and impact less on global warming than traditional plastics, they could have other environmental impacts caused by fertiliser, pesticide and land use change required for agriculture production as well as from the fermentation and other process steps.

Plastics Europe compared research on two bioplastics: a PLA bottle and LDPE (low density polyethene) film based on ethylene derived from renewable resources. The benefits derived from these depended on the choice of feedstock and waste management strategies. The environmental impact of PLA bottles was more variable than PET bottles and. in some cases, production methods contributed to a more negative impact on the environment overall. On average, the PE film based on renewable resources produced two to three kilogrammes less CO2 per kg compared to PE derived from fossil resources, but this depended on the choice of feedstock and how the waste was managed.

Dust to dust

Another key issue is consumer understanding of bio-plastics and the difference between bio sourced polymers and bio-based plastics, as well as biodegradable vs compostable packaging. While many think biodegradable and compostable packaging is under-utilised by brands, most do not realise the materials require industrial composing and will nor break down at the same speed in domestic compost systems or in the general environment. Consumers often also believe that compostable packaging decomposes leaving zero trace in the environment and do not consider the carbon dioxide released.

In addition, other components of the package have an effect. Using biodegradable material for the bottle should surely mean all the other components are equally biodegradable? Using paper or a biodegradable plastic for the label is possible but using biodegradable material for the closure is still a challenge and biodegradable adhesives (for the label) are still being developed.

Aqua British, midlands spring water, has recently launched a pack where the bottle, closure and label are fully (sugar cane) bio sourced and biodegradable (compostable).

The issues around compostable packaging only being suitable for industrial process are beginning to be addressed by making bio-degradable polymers suitable for home composting or landfill degradation. However, this seems an anathema as this means the material is lost and simply adds carbon dioxide to the environment. For this reason, biodegradable polymers are not considered suitable for the EU circular economy model.

USA-based Chlorophyll Water has a plant-powered purified water enhanced with chlorophyll, and bottles have an integrated a proprietary organic additive that accelerates the natural biodegradalion in biologically active landfills and anaerobic digesters.

Plastic free moves have also focused on consumer multipackaging. The main issue with recycling the film used for these packs is in the print, the high level of inks makes effective recycling virtually impossible although some work is being carried out to solve these issues, by de-inking processes or developing inks that do not affect the recycling process.

Because of these issues, a number of beverage companies have started to move from film based multipacks to fibreboard alternatives for cans using a variety of formats, from fully enclosed wrap to a simple top clip which uses minimal board. But the availability of sufficient quantities of suitable quality fibreboard is starting to become an issue and may restrict further developments or push prices higher.

Systems to bond the primary packs together using specially formulated adhesives are being developed. The KHS Nature MultiPack has been used by Carlsberg for cans and Evian for PET bottles. However, anecdotal feedback from some consumers has indicated issues with consistent detachment of individual packs.

Significant publicity has been given to alternatives to plastic bottles, namely glass and aluminium (or steel) cans. Many environmental groups and companies are promoting these as the answer to the 'plastic problem', but often they are only looking at the plastic waste issue and do not consider the carbon footprint of these alternatives.

As with plastics, comparing the carbon footprints of these alternatives is not easy for an expert, let alone the general consumer. The table below shows the comparative footprint of typical container materials although differences in the relative weight of the container and supply chains give rise to significant variances in the footprint of a container.

|

Material |

Baseline Kg CO2/tonne |

Typical wt (g) of 500ml container |

Kg CO2 per (g) |

Kg CO2 per pack |

|

Aluminium |

6,960 |

10 |

0.0070 |

0.070 |

|

Steel |

1,870 |

18 |

0.0019 |

0.034 |

|

PET |

4,190 |

22 |

0.0042 |

0.092 |

|

Glass |

750 |

310 |

0.0008 |

0.233 |

Methodology for assessing the climate change impacts of packaging optimisation under the Courtauld Commitment Phase 2 - WRAP Dec 2010

While there are different opinions, the general view is that the use of plastic bottles, with efficient recovery and recycling has a lower overall footprint compared to glass bottles or cans. Coca-Cola have taken this stance.

Other factors to consider are the usability (weight) and limits of glass (fragility in public places) as well as the capacity for recovery and recycling.

Fill and go

As well as looking at alternative materials, a number of beverage companies are looking at developments in vending and dispensing formats. There has been a significant increase in the dry foods, delicatessen, cooked meats and toiletries sectors where consumers take and refill their own packs in store. However, there are issues around the responsibility for the cleanliness of the packs, do consumers understand risks and are they prepared to take full ownership for this if there are health issues?

ln terms of beverages and refillable packaging, for in home use PepsiCo is promoting and expanding its SodaStream system and has targeted a reduction of 67 billion bottles to 2025. It is also switching the supply of flavours and ingredients to glass bottles. A version has been launched for refillable bottles for use in schools and offices.

PepsiCo's Drinkfinity system is available in the US, combining a reusable container with a recyclable ingredient pod that provides a choice of beverages from caffeine based stimulant to botanical relaxing drinks. Gatorade Gx is a similar system aimed at the energy/sports consumer, again giving a choice of hydration and energy options.

A number of companies are developing innovative vending systems for retail outlets from gyms to cinemas. Both PepsiCo and Coca-Cola are developing intelligent vending machines with 200 or more variables. These use a personalised re-useable cup with a microchip or an NFC enabled phone to save the consumer’s choice and interact with the machine to personalise the drink to consumer specification. For energy or sports drinks, this can include the ability to personalise the electrolyte, and carbohydrate levels.

Elemental Beverages, in the USA, have patented the Snapchiller, which uses advanced thermodynamics to chill hot brewed fresh beverages into cold drinks on demand. Regarding dispensed drinks for bars and clubs, the London Essence Company has unveiled Fresh Serve to move tonic dispense into the arena of premium drinks. The system uses micro-dosing to blend a tonic base with chilled carbonated water and then adds botanical flavours.

Reducing environmental impact

Following a number of increases in oil prices and before the focus on plastics gained momentum. The primary areas for development were all focused on removing materials (light weighting) and reductions in energy use, in the manufacturing processes - primarily as a cost reduction exercise, but more recently also promoted under the environmental banner.

The soft drinks industry has a number of initiatives to reduce process water volumes (i.e. water not contained in the product), improve effluent management to minimise waste product going to drain as well as recovering process scrap for recycling. Here, the focus is on the packaging materials and processes, material reductions and energy efficient manufacturing processes.

Over the past 20 years or so, the weight of a 500ml PET still water bottle has been more than halved from over 20g to around 10g or less. A number of recent developments such as Sidel's X-Lite (6.5g) bottle and KHS Factor 100 PET (5g) bottle have pushed weights even lower.

Other developments have allowed Light weighting of hot fill PET bottles which need additional material to compensate for the vacuum developed alter cooling. The Sidel BoostPRIME process balances this negative pressure by re-forming the base after cooling the bottle.

On older stretch-blow machines, the operators are required to complete regular quality control checks to monitor the bottle quality and then make process adjustments, which meant the bottle weights were often higher than optimum to allow for process variance. Most of the machine manufacturers are developing and offering various levels of automated process control. which monitors the finished bottle and uses the feedback to adjust the heating and stretching/blowing process to optimise the material distribution in the bottle. This in turn reduces the normal fluctuations and results in improved bottle stability, so facilitating the use of lower preform weight which is proving to be a significant challenge where those preforms have a high recycled PET content.

A further development of the preform heating stage is the use of laser or microwave systems rather than the current infrared systems. These can give better heat penetration and targeted heating to reduce energy consumption and give a faster process time.

Also of interest is the KHS FormFill machine where after heating the preforms as in a conventional stretch/blow machine, the bottle is formed directly using the product to be filled as opposed to blowing with compressed air and then filling.

Circular economy

Another significant challenge for packaging is the consumer demand for easy to use and convenience packaging vs designing for recyclability and minimising plastic and other materials. Overcoming this will require changes in both container design and function, as well as changes in consumer behaviour to use and separate packs. In addition, technical vs practical recycling comes into play, many packaging items are technically recyclable, but in practice cannot be separated or systems are not economic.

However, the packaging and brand owners also have a big part to play in helping consumers with consistent, informative labelling. A simple survey of small PET bottle packaging shows a huge array of recycling symbols and guidance used across the drinks and water sector, even between different products from the same brand.

Current UK recycling rates are low and need to be much higher if we are to move to a circular economy. The first question is how to encourage consumers to separate and recycle materials more. For example, despite being widely publicised and requiring little input from the consumer, the recycling rates for cans varies considerably across the UK.

If we are to move to a circular economy, recovery rates and recyclate quality must be increased by improving the recovery systems while at the same time changing people's habits. Currently only a small percentage of consumers are really environmentally conscious and actively separate and clean materials for recycling. The vast majority will separate materials if it is easy and requires little effort and there are some who will make no effort unless forced to by either a fine or a significantly high deposit.

Legislative proposals for deposit schemes may well go some way towards this, but possibly at the expense of local authorities who fear domestic collection rates will drop, depriving them of income from high value materials. Currently there is a high degree of confusion amongst consumers over what materials can and cannot be recycled. as well as significant differences between what individual councils will or will not collect and how it is collected. The output from a recent government enquiry on recycling systems indicated the vast majority of both individual consumers and organisations want the collection systems standardised nationwide, both for the range of materials collected and the containers/identification systems.

There is also the challenge of ‘on the go' recycling and ensuring public recycling bins are numerous enough to enable people to dispose of packing with little effort, and emptied appropriately so as not to overflow or force people to use the wrong bin.

But once the material has been collected, separating and recovering the different materials is also a challenge. Most systems are currently either manual/visual or use near infrared optical systems to separate materials, but both have limitations. A number of 'tagging’ systems are being developed which will enable better recognition and improve sorting in automated systems or give consumers guidance to separate materials.

One system is Polytag, which uses a specially developed printing process to 'tag' each item of packaging with a unique code at its point of manufacture. This tag is stored on a database and then traced by consumers via a mobile phone app so it can be separated from the recycling waste stream and reprocessed in batches of identical-grade and colour plastic. The system is currently under trial in the Wirral, however the need for consumer input may be an issue as most people do not see it as their responsibility to sort and separate materials for recycling.

Another possibility is the use of an ‘invisible bar code’ a microscopic change in a pattern of pixels enabling software to identify the package so it can be sorted and recycled correctly. Repeating copies of the code are embedded in multiple positions on the label, so even if a package is crushed and damaged or facing in a particular direction, the cameras can usually still see the information. For packages without a label, the bar code can be hidden in a microscopic pattern embossed in the plastic. A number of major brands have collaborated with Digimarc, the company that developed the technology.

The Polymark consortium has recently published a preliminary report on the development of food-contact approved chemical markers to improve identification and sorting of higher value elements, particularly PET, in the plastics waste stream. The markers are applied to the packaging as a water-based sprayable coating which, after sorting and separation is removed under the processing conditions already in use within recycling plants, thus preventing marker accumulation on recycled materials.

There are a number of dedicated return and recycling systems for packaging materials. In one scheme, TerraCycle has collaborated with Hi-Cone to set up a recycling programme for beverage ring carriers. The consumer separates and returns the carrier either by post or at a drop off centre. However, there is the question of how many consumers will bother to separate and send materials or take them to a separate collection point.

As described above, while the use of biodegradable plastics is currently low, if there is a significant increase in use, there will need to be significant investment in the recovery and processing systems as well as informing and educating consumers regarding separating these materials. To ensure the material is separated from conventional PET, the collection and recovery infrastructure would require an additional waste stream to what many people see as an already complicated system and is still likely to result in bio polymer contamination of traditional plastics recycling. which even at levels of 1 or 2% is enough to significantly affect the quality. Due to this lack of infrastructure, the use of bio-degradable plastics is not supported by some major retailers (Tesco, Morrisons, Aldi) and they currently will not stock products using them.

Once the packaging has been collected and separated, there is still the need to clean and recycle the materials, either back to high end use or downcycle to secondary use. Regarding the use of recycled PET (rPET) in soft drinks bottles, one of the key challenges is currently the shortage of good quality recyclate. This has the effect of pushing up the price which makes its use less financially viable.

There is also the issue of consumer perceptions of rPET. Whatever recycling process is used, the fact that the source is consumer waste is variable, this results in variance in the recovered PET which shows as both a noticeable colour variance in the finished bottle and creates greater variance in the heat absorbance during final blowing, so requires greater monitoring and adjustments to the process controls.

There are a number of developments and collaborations to improve the availability of quality rPET in the market as well as using lower grade recycled materials for high end and food contact use.

BP has developed an enhanced recycling technology, BP lnfinia, that enables unrecyclable PET to be recycled into new, virgin-quality feedstock. The company has also formed a consortium with Alpla, Britvic, Danone, Unilever and the recycling specialist Remondis to develop and commercialise the lnfinia recycling technology.

Coca-Cola has partnered with loniqa Technologies, lndorama Ventures and Mares Circulares to produce test bottles made using 25% recycled marine plastic retrieved from the Mediterranean Sea and beaches. While this was only developed as proof of concept, it has shown what the technology may achieve in time.

Work is being carried out to develop biorecycling using enzymes to break down the polymer structure. French company Carbios has created a biological solution to fully recycle plastics using enzymes to break down PET back to constituent monomers which can be purified and used to produce recycled material similar in quality to virgin material.

As well as improved consumer labelling, there will also need to be increased focus on designing packs for recyclability to facilitate separation and recovery in the recycling process. A number of companies are looking at label, sleeve and adhesive technologies in this area.

Avery Dension has developed Cleanflake, a water-based adhesive which adheres to the PET bottle but will separate in the recycling process. UPM Raflatac came up with the SmartCircle range of washable label materials for PET and glass. The PET label will separate during the PET recycling and the glass label will wash off in standard industrial washing processes for recycling or refillable bottles. CCL’s solution is the EoStream label which shrinks and detaches from the PET during recycling.

While some people support downcycling as an alternative to recycling, this only goes part way to creating a circular economy. While is does prevent virgin materials being used for low grade use where recycled materials will do the job, ultimately everything will end up at the bottom of the recovery chain.

But it will have a part to play where materials cannot be recycled in a circular system or where there is a surplus. For example, researchers at De Montfort University Leicester (DMU), UK, have successfully manufactured a prosthetic limb socket made from recycled PET bottles. The material was granulated and used to spin polyester yarn, which was heated up and moulded into prosthetic limbs. This system is claimed to be significantly cheaper than traditional methods.

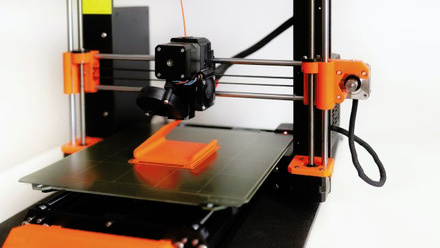

A number of companies now offer 3D printer filaments made from recycled PET and various developments aim to reduce the use of single use packaging, in particular plastic and both the EU and individual countries have or are planning a range of regulations restricting or banning single use items.

The EU parliament recently approved the Single Use Plastics Regulations which covers a wide range of plastics, both packaging and non-packaging, with some single use items banned or restricted, mandatory minimum recycled material content and the use of tethered closures on all beverage containers under three litres. While industry and international standards are currently being developed to meet this requirement, there is some industry concern over the effectiveness of the regulation and the additional plastic required to meet the requirements.

The French parliament has recently passed a law banning the free distribution of plastic bottles in public and business places as well as the use of plastic single use cutlery etc. Furthermore, it intends to ban all single use plastic by 2040.

There are also instances of employers banning the use of single use plastics in the workplace and writing this into employee contracts.

Multiple use

While the question of recovery and recycling versus re-filling of bottles for soft drinks has been debated for several years, the in-store re-filling of the consumers own container is a growing area in some sectors, dry goods and toiletries being two common areas. Many see returnable/refillable containers as the solution to the plastic problem, but a number of studies have shown the energy (carbon emissions) required for the heavier weight of the container (to enable repeated use), their collection, sorting and washing of refillable containers is comparable to the energy required for bulk collection and recycling. There are also issues with contamination and ability to clean refillable containers as consumers can them for other materials (cross contaminating foods, solvents, etc.).

A bottle collection system will also require consumer input to separate and return the containers which would require significant changes to the existing collection infrastructure and may not be viable as a national system, but some localised systems are already in place. TerraCycle in conjunction with a number of major brands have piloted a returnable packaging shopping platform in Paris and New York - Loop where the empty packs are collected, refilled and reused. For this type of system of refillable packs to expand, consumers will need to be prepared to separate the empty packs for return via different systems.

Socially conscious consumer

There is an increase in more socially conscious consumers that tend to avoid big brands and are looking to help the environment by avoiding plastic packaging, buying locally produced goods to support local business and reducing food miles. In the case of drinks, many niche healthy drinks are produced by small entrepreneurs or small start-up businesses where the focus is on the product (liquid), with simple low-cost packaging with minimal capital investment.

This generally means preformed containers and semi manual filling/packing processes so the carbon footprint of supplying the packaging materials to these producer/packers is often relatively high. Therefore, the benefit of buying local produce is often counteracted as the packaging may have travelled many hundreds of miles, wid1out the benefits of bulk transport efficiencies.

One innovation in this area are communal or co-operative processing plants. For example, growers can take their fruit to be processed and pressed, the juice is then bottled and labelled for the grower to sell. While mobile filling and corking of wine has been practiced in France for many years, there are also a number of companies operating mobile canning units which allow small (craft) brewers to have their product canned, so reaching a wider consumer base.

Health conscious

The increasingly health conscious consumer has resulted in a growing demand for a choice of drinks for specific occasions or as part of a healthy lifestyle - functional products (vitamins etc.) with a proven or perceived health benefit, ‘clean label' (preservative free, natural ingredients) drinks, juice-based drinks (not pure juices) and exotic flavours. These in turn have driven the increased use of aseptic and clean filling systems or in pack sterilisation as well as packaging with barrier systems.

For microbiologically sensitive products, an alternative to using aseptic filling technology is to use either in-pack pasteurisation or high-pressure processing once the container has been filled and sealed. But these systems are creating new challenges for the closure sealing and pack integrity.

During high pressure processing (HPP), the filled and capped bottles are placed in a chamber filled with water and pressurised to around 85,000 PSI for several minutes. This pressure results in the product containing almost no living microbes, thus extending the shelf life to 30-45 days. Plastic containers and closures are used as they are able to flex and recover during processing, but even then, the pressure creates significant challenges for the container and closure seal. Using standard containers and closures is likely to result in process water entering the container during processing.

Even if the product does not require any in pack processing, many vitamins and flavours are sensitive to oxygen or light, so unless the product is given a very short shelf life, some form of barrier system is required. While the packers of many of such products are using glass bottles as they provide the necessary barriers (and are perceived as preferable to plastic), for some the weight and fragility of glass may be an issue. Where a plastic bottle is preferred, there are a number of options that may be used.

For smaller volumes and packers, two options that have good performance history are available, either multi-layer (co-extruded) bottles or oxygen scavenging additives. The challenge is that where the barrier material is more than 3% to 5% by weight of the container, the recyclability is significantly impacted.

Another more recent development is the use of coatings on the bottle. A number of systems available such as KHS FreshSafe PET, Sidel Actis Coating or Krones BestPET, where a thin barrier layer is applied to either the inner or wall of the PET bottle, which is washed off by the caustic in the recycling process. While the coated bottles have a lower unit cost, this is offset by the capital cost of the additional equipment so is only cost effective for high volume brands.

An alternative to barrier systems to protect sensitive ingredients is to keep them separate in a stable (liquid or powder) form and add them when the pack is opened for consumption. A number of systems are now available where the action of opening the closure for the first time adds the flavouring and/or vitamins. Some also allow the consumer to vary the level of a flavour or other ingredient to their own preference.

Sports closures have been in use for some time, either push/pull or flip top (with or without a valve). But even with these closures, the light weighting of PET bottles has now reached the point where some bottles are difficult to use when used one handed during sport or when exercising. One option which has been available for some time is the SmartSeal non spill closure, where the pressure in the bottle acts to close the seal and is opened by the action of drinking.

Changing markets

The demise of the high street has been well publicised, but e-commerce and the shift to the online world will continue to grow and put pressure on the traditional markets and outlets. As a result of this availability people now shop more often, with a 'buy for tonight' expectancy.

Beverage packaging has almost exclusively been developed with fixed size transit packs and formats for the rigours of traditional supply chains. But the e-commerce supply chain is significantly different - unit numbers are not known until the time of order and single parcel delivery is often the main method for distributing goods. Packs will often experience multiple drops where the effect of hydraulic shock on the closure/seal can be severe and the pack will be subject to compressive loads and/or shocks in all orientations.

A wide range of cushioning packs exist, both fibre or plastic based but simply adding more secondary packaging and cushioning is not the answer as consumers will not accept large quantities of packaging and kerbside collection systems become overloaded. Some companies are looking at redesigning the primary pack specifically for e-commerce to minimise both materials and damage.

One example is Letterbox Wine by Garçon Wines, a flat wine bottle that can be delivered through a letterbox.

The e-commerce challenge has also resulted in a 'one size fits nothing' scenario and secondary packaging machine suppliers are developing end of line systems which can handle different pack formats to meet varying needs

Aging population

We have an aging population with limited and reducing dexterity. At the lime of writing, 32% of the world's population was born after year 2000. In Britain there are now more people aged over 65 than under 16 and in the next 20 years, the number of people over 80 expected to treble and over 90 expected to double.

As discussed, many packs have been light weighted by reducing size and thickness, significantly limiting accessibility to those with reduced dexterity. As the population continues to age, openability and accessibility will be an ever-increasing requirement. A pack than cannot be accessed by older people will reduce the potential customer base for a product, so the key to maximising the customer base is developing products that are universally accessible by all.

The easiest way is to reverse weight reduction and simply increase closure size and pack stiffness to aid grip, but this is counterproductive to minimising the use of plastic. The challenge is how to minimise packaging without reducing accessibility.

For beverage packaging, one option is to use lacquers and slip additives to reduced opening torque but there may be potential issues with seal integrity. The other is to make the closure easier to grip by the use of increased knurling or soft grip coatings.

Whatever system is used, retesting the packaging to ensure it can be used by those with reduced mobility is essential. The University of Cambridge Inclusive Design system is an innovative system to assess and test packaging for use by everyone.

Summary

The two months or so taken to research and write this article has highlighted the sheer number and speed of innovation in beverage packaging and how consumer trends and pressures are changing or being changed by packaging. This pace is not going to slow down, if anything it will get quicker. But the overall driver must be the environment and carbon reduction, driven by responsible use of packaging, including plastic where appropriate.

Text © David Rose January 2020.