Cracking the crud problem in nuclear reactors

A new design for fouling-resistant materials could thwart corrosion of nuclear systems. Shardell Joseph finds out how.

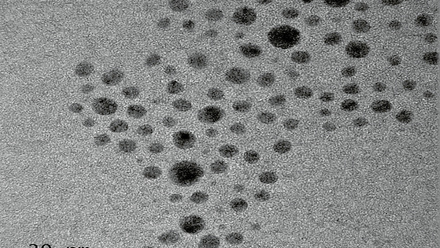

The sticky problem of chalk river unidentified deposit (crud) particles adhering to nuclear reactors is set to be unstuck, say researchers at Massachusetts Institute of Technology (MIT), USA.

Their proposed anti-fouling materials are made from titanium carbide (TiC), fluorinated diamond-like carbon (F-DLC) and amorphous carbon, which is the same anti-scratch and corrosion coating used on iPhones. Selected for having very low van der Waals (vdW) forces when immersed in water, Michael Short, Associate Professor of Nuclear Science and Engineering at MIT, describes the components as ‘theoretically and really very slick.

‘Simply put, no one has been able…to stop [crud] being formed, or to stop [it] sticking in the first place. We focused on the latter, as the former looked too hard.

‘[The anti-fouling materials] prevent the first little layer of crud particles from sticking, either making the coatings very slick, or making the adhesion of the crud so weak that fast-moving water can rip them off before they build up.’

By preventing the build-up of crud within the reactors, the materials can thwart crud-induced localised corrosion and power shift – the impact of boron-containing compounds in the water, normally used to control the reactor, becoming concentrated making it harder to control.

According to Short, the design principle was to ‘match the optical properties of the fuel rod coating to the surrounding water as closely as possible in the whole electromagnetic spectrum. [We] focus specifically on the near-IR, visible and near-UV wavelengths, though they all technically do matter. Then theory predicts very low vdW forces, and that’s what we’ve seen too’.

The researchers made significant progress when they began to consider vdW forces. Inspired by a 50-year-old equation developed by Russian physicist Evgeny Lifshitz, they coated the cladding of the fuel rods with a material that matched the electronic frequency spectrum of coolant water, so the particles slip right past the fuel rod. ‘We could rule out other surface forces for simple reasons, but one force we couldn’t rule out was vdW,’ continues Short.

‘Lifshitz’s theory described the magnitude of vdW forces according to electron vibrations, where electrons in different materials vibrate at different frequencies and at different amplitudes, such as the stuff floating in coolant water and fuel rod materials. His math tells us if the solid materials have the same electronic vibrations as water, nothing will stick to them.’

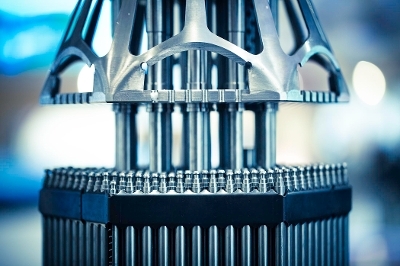

The team has tested the materials by building a flowing reactor loop without the irradiation. ‘We call it the IHTFP (integral heated testloop for pressure water reactors), and it recreates all the conditions in a nuclear reactor, but without the radiation,’ Short notes. ‘They came out shiny. That’s all we had to see. The MIT reactor tests showed that the coatings survived, so they’ll still be around (at least after that long) to do their job.’

USA nuclear electric power generation company, Exelon, plans to test the anti-foulant designs in one of its commercial reactors. Exelon recently funded the research, as well as The Electric Power Research Institute and Statoil/Equinor.

Short adds, ‘We’re hoping to try lead test rods in 2022. Then they’ll cook for 18 months, and if they come out shinier than the rods nearby, then we’ve succeeded.’