Cobalt-copper tandem converts carbon dioxide to ethanol

Positioning cobalt and copper in close proximity on an electrode facilitates selective conversion of CO₂ to ethanol.

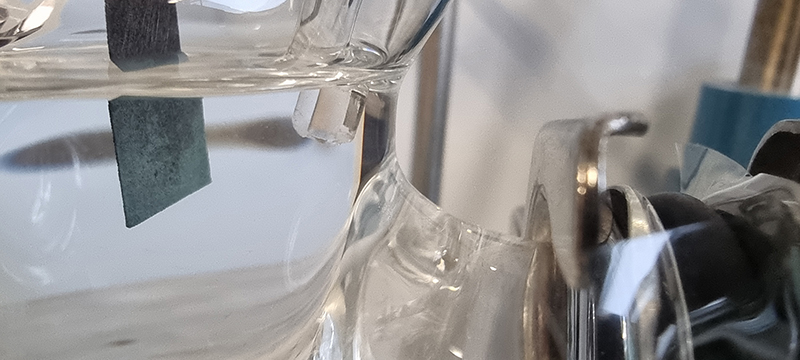

The cobalt-copper electrode responsible for the conversion of carbon dioxide. On completion of the process, ethanol is present in the aqueous solution

© Julius WetzelResearchers at Johannes Gutenberg University Mainz (JGU), Germany, have published a method for effectively converting carbon dioxide into ethanol, which is then available as a sustainable raw material for chemical applications.

‘We can remove the greenhouse gas CO₂ from the environment and reintroduce it into a sustainable carbon cycle,’ explains Professor Carsten Streb from the JGU Department of Chemistry.

The lab-scale work shows how carbon dioxide can be converted to ethanol by means of electrocatalysis. Assuming green electricity is used for this process, it would also be sustainable – and food crops currently used to produce ethanol for fuels would be available for food use. The research results have been published in ACS Catalysis.

The electrochemical conversion of CO₂ to multicarbon products, such as ethanol, would be an ideal way to obtain high-energy density fuels and valuable chemical raw materials, while at the same time using CO₂ as a precursor and thus removing some from the atmosphere.

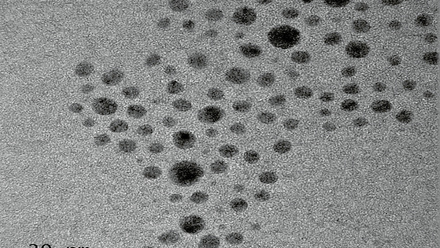

The team designed an electrode coated with a black powder containing cobalt and copper. The two metals must sit in very specific positions on the electrode. ‘The initial challenge is to get carbon dioxide to react,’ explains Streb. ‘The bonds between the atoms of the molecule are very strong, but cobalt can break them.’

This initially produces carbon monoxide, so in a second step, copper is used to carry out the reaction to ethanol. ‘However, this only works if cobalt and copper are close to each other on the electrode,’ notes Streb.

‘By using globally available raw materials as catalysts, we are following an approach in current research to increasingly focus on non-precious metals,’ Streb says.