Caring for our bridges

Calls for pro-action in retrofitting concrete bridges.

Many transportation bridges around the world are more than 50 years old, and some are nearing, or have already reached, the end of their intended lifespan.

Common defects identified during inspections are related to the material ageing, such as corrosion of steel reinforcement and spalling of concrete. Additionally, new challenges are posed by climate change and population growth, like temperature fluctuations and flooding, along with increasing traffic volumes. These are accelerating structural deterioration and significantly increasing the risk of failure.

The closure of Clifton Bridge in Nottingham, UK, in February 2020, serves as a prime example of how conditions can jeopardise structural integrity. Corroded internal tendons were discovered during a routine inspection of the deck, leading to its closure.

Carrying more than 100,000 vehicles daily, the bridge’s closure, which lasted for 20 months until strengthening measures were completed, resulted in severe economic consequences and disruption to daily life.

Unfortunately, this is not an isolated incident. Recent bridge collapses in Europe highlight the urgent need for retrofitting and taking action to reduce the vulnerability of existing stuctures.

Examples include the Morandi bridge in Genoa, Italy, in 2018, which resulted in 43 deaths and £360mln of damage; the Carola bridge in Dresden, Germany, in 2024; and a pedestrian bridge over the London-bound M20 in 2017 in the UK. Meanwhile urgent repairs were needed to avoid the collapse of the Hammersmith Flyover in London in 2020.

Recent data obtained through the Freedom of Information Act from England’s National Highways, reported in the media, shows nearly half of the country’s 9,000-plus bridges on major A-road and motorway networks have sections in ‘poor’ or ‘very poor’ condition, which can significantly impact their capacity.

Recognising the need for resilient infrastructure, the UK Government’s 2020 National Infrastructure Strategy emphasises retrofitting as a priority to enhance resilience, reduce carbon emissions and generate economic benefits.

This aligns with international initiatives, such as the G20 Finance Track Ministerial Meeting in 2021, which identified infrastructure maintenance as a top priority. The meeting concluded that “good and timely infrastructure maintenance boosts prosperity, enabling growth and well-being of people, firms and economic systems.”

Retrofitting existing bridges is not just a necessity, but an opportunity to employ innovative, sustainable solutions that extend service life while reducing environmental impact.

Bridging the gap

The University of Nottingham, UK, and Luleå University of Technology (LTU) in Sweden are taking a significant step towards sustainably retrofitting ageing concrete bridges. The project is funded by the UK’s Royal Society and titled Climate Adaptation for Resilient Bridges (CARE).

They are using fabric-reinforced cementitious matrix (FRCMs) composites as an alternative to fibre-reinforced polymers (FRPs), which are commonly used for retrofitting and strengthening applications.

FRPs come in various forms, including thin unidirectional strips that are approximately 1mm thick and typically manufactured through pultrusion. Additionally, there are flexible fabrics made of fibres arranged in one or more directions – these are usually impregnated with resin onsite, although pre-impregnated options are available in rare cases.

FRPs offer several advantages. They are easy to apply, allowing for rapid installation with minimal disruption to occupancy. Additionally, they are non-corrosive and lightweight – roughly one-quarter the weight of steel – while providing high tensile strength and stiffness that can be customised to meet specific design requirements.

Furthermore, FRPs come in a range of sizes, geometries and dimensions. FRPs can be produced in the form of rods, which have diameters of a few millimetres, and are also made through pultrusion.

However, there are notable disadvantages associated with FRPs. They tend to be expensive, may have compatibility issues with concrete and can degrade prematurely when exposed to high temperatures due to the presence of resin (e.g. in case of fire).

FRCMs refer to a new generation of composite materials, specifically mortar-based composites. In these systems, textile materials – such as fabric meshes made from long woven, knitted, or even unwoven fibre tows – are embedded within the mortar, typically oriented in at least two orthogonal directions. Instead of using resin as the bonding material, these systems use mortar.

This category includes textile-reinforced mortar, steel-reinforced grout and other related systems. The use of mortar, particularly when cement is substituted with supplementary cementitious materials, makes it a more environmentally friendly and sustainable solution. Additionally, mortar offers benefits such as fire resistance, compatibility with concrete surfaces, cost efficiency, improved vapour permeability and reversibility.

The CARE project aims to enhance global understanding of FRCMs by experimentally and numerically studying their durability under repeated load cycles and extreme temperatures.

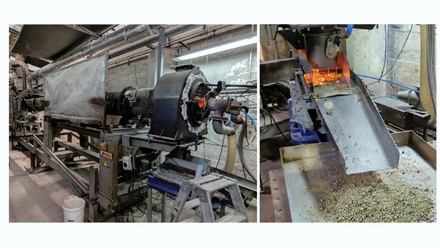

To achieve this, a full-scale, reinforced-concrete, trough railway bridge has been constructed at LTU. This is part of a larger project carried out by LTU and funded by Trafikverket, the Swedish Transport Administration, to investigate the performance of ageing bridges.

This bridge features geometry, mechanical properties and reinforcement layouts typical of short-span railway bridges found in northern European countries. It consists of two longitudinal beams that support a slab, forming a U-shape. This U-shaped design acts as a container for the ballast and railway track.

An analysis of the Swedish bridge population has found that a typical, single-span, trough bridge has an average span length of 6.8m and a width of 5.4m. Based on this information, a reinforced-concrete trough bridge was constructed at LTU, using a design close to these average dimensions.

The construction employed C40 concrete and KS40 reinforcement bars. The railway tracks used UIC60-type rails, with a class I ballast that has a height of 27cm from the top surface of the concrete slab to the sleeper bottom. Additionally, the sleepers are equipped with fast clippers.

The bridge has been subjected to both static and cyclic loading, with axle loads increasing from 250-325kN to simulate real-world traffic conditions. Testing is ongoing, with 10 million out of 20 million cycles completed so far.

Displacement and strain measurements at various load stages indicate a gradual loss of structural stiffness. Additionally, increasing strain in specific sections of the bars correlates with observed concrete cracking, confirming progressive deterioration. Once the testing is completed, the remaining capacity of the bridge will be assessed, and an appropriate FRCM-strengthening configuration will be determined within the CARE Project framework. The bridge will then undergo additional testing.

The results of this project will directly inform retrofitting strategies, ensuring that bridges can withstand environmental changes and increasing traffic loads, while maintaining the same loading history as the original bridge.

Testing of mortar-based composites will also showcase their effectiveness in addressing defects.

The methodologies and technologies developed could be implemented globally, establishing new standards for managing ageing infrastructure around the world. Additionally, the project will significantly benefit society by providing safe and sustainable infrastructure, promoting a greener economy, and reducing economic losses caused by severe damage and bridge closures.