Carbon fibre advances massless energy storage

The multifunctionality to commercialise massless energy storage has been achieved at a Swedish university.

A major limitation of any battery-powered item is the battery weight, whether in a laptop, electric vehicle, or plane. A promising solution is massless energy storage, where a lightweight battery acts as a structural component.

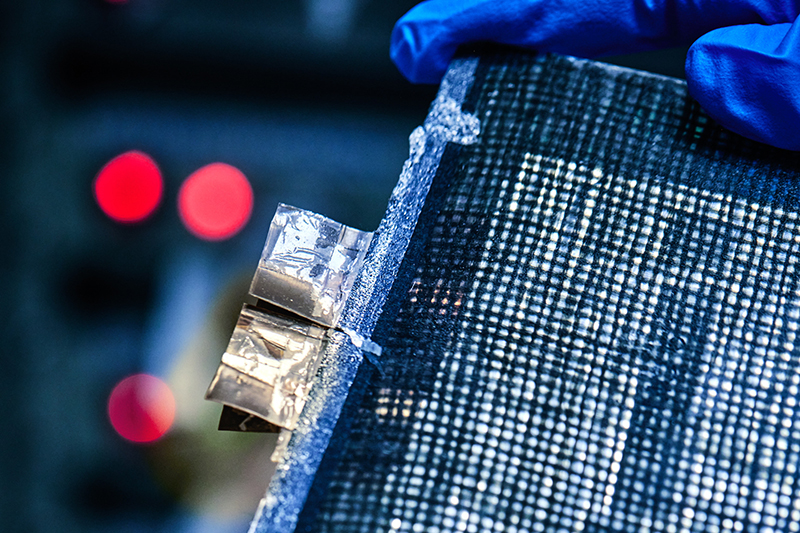

The device from Chalmers University of Technology is based on a composite material and uses carbon fibre (CF) for both electrodes.

The positive electrode is coated with lithium iron phosphate. In the anode, the CF acts as a reinforcement, an electrical collector and active material. In the cathode, it acts as a reinforcement, current collector and scaffolding for lithium.

Since the CF conducts the electron current, the need for heavier materials like aluminium or copper is reduced.

The researchers, led by Professor Leif Asp, demonstrated in 2018 that CF could store electrical energy and be used in lithium-ion batteries. They have since worked to improve both the energy density of the batteries and the elastic modulus, both necessary for commercialisation.

An elastic modulus of 76GPa, increased from 25GPa, means that the material can support loads at the same rate as aluminium, with a lower weight. Meanwhile, the team has also made progress in energy density, increasing it from 26Wh/kg to 30Wh/kg.

Dr Richa Chaudhary at Chalmers compares the multifunctionality of their device to the human skeleton and highlights its material capabilities.

Traditional batteries, explains Chaudhary, 'are bulky and only serve as energy storage devices, which adds significant weight to applications like electric vehicles. The structural battery design addresses the problem of added weight by integrating energy storage and structural support into a single, lightweight component.'

Chaudhary reports that 'testing involved evaluating both the mechanical properties (i.e. tensile strength and stiffness) and electrochemical performance of the batteries.

'Advanced manufacturing techniques, such as electrophoretic deposition, were employed to prepare positive electrodes in a green and sustainable way. The structural batteries were rigorously tested for their ability to bear mechanical loads while storing energy, optimising them for applications in electric vehicles and aerospace.'

This multifunctionality offers potential for sensing devices and wearable electronics as well, which will be part of the team’s on-going research. The products the technology is likely to assist sooner are mobile phones and laptops with significantly reduced weights.

However, the goal is to impact the transport industry’s energy needs, where Asp believes the technology can make the most difference. The steps needed for scalability remain significant.

The battery uses a semi-solid electrolyte to transport the lithium ions between the battery terminals. This reduces the risk of fire, but further research is needed to generate the higher levels of power required.

Also, while lithium-ion batteries continue to have a much higher storage capacity, the reduced weight and structural component of massless energy-storage batteries means lower storage capacities can be equally effective overall.

Moreover, by focusing on CF, a well-established material with a high strength-to-weight ratio suitable for industrial-standard mechanical reinforcement, the team hopes to achieve a performance level and process for commercialisation.

The pathway to commercialisation is already being explored through collaborations with industry partners and Chalmers Venture company Sinonus AB.