Can plastic self-degrade in the sea?

A University of Edinburgh, UK, start-up E.V.A. Biosystems is developing 'selectively degradable plastics'.

The founders want to ultimately enable plastic packaging to ‘sense’ its surroundings and only degrade in landfill or seawater.

Co-founder Dr Alex Speakman says they are engineering their own bacteria to release enzymes that break down plastic in the environment at the molecular level – from polymers into monomers and beyond – and use it as a source of nutrients. His team plans to accelerate those mechanisms and apply them with greater control for 'selective degradation'.

Speakman says, 'Bacteria are naturally fantastic at responding to their environments, they need to be in order to survive. We’ve been able to use naturally occurring bacterial salt-sensing mechanisms and design new synthetic biological parts in order to detect a seawater-equivalent concentration of salt and produce degradation enzymes in response.'

The company recently won top prize in the Net Zero category at Scotland’s Converge awards, which celebrates academic innovation – netting £30k in cash and nearly £20k in business support to propel the technology forward.

The firm says, 'Synthetic biology provides novel solutions to many issues, yet it remains out of reach, sequestered in labs and used on small scales. This includes issues such as the poor biodegradability of plastics filling the oceans with waste, the efflux of toxic waste from dyes in the textiles industry, and the high cost of biomolecule detection, such as the RNA of COVID-19.'

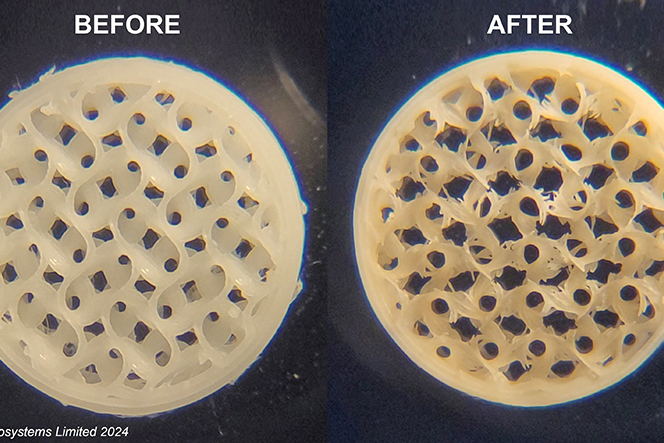

They have produced custom 3D printer filaments with bacteria embedded inside, and then 3D-printed parts that are placed in solutions that are salty – at a concentration equivalent to seawater – or non-salty.

A fluorescent reporter reveals that the plastic parts in high-salt conditions produce degradation enzymes in response to their environment. 'This was really exciting to show that we can produce plastics for manufacturing that can tell if they have entered seawater conditions and then do something about it,' reflects Speakman.

As plastic degradation is not a smooth transition, with intermediate molecules along the pathway, the team aims to use a customisable biological format of the technology to produce enzymes for each intermediate step along the chain. In this way, they hope to break down plastics as completely as possible and minimise microplastic production.

For commercial production, Speakman envisages the bacteria being mixed into plastics at either the point of manufacturing feedstocks, such as nurdles, films or filaments, or, where techniques and equipment allow, as an additive just before final production.

'Our intention is to make it as easy as possible for manufacturers to work with our product using their existing manufacturing equipment and protocols,' reveals Speakman.