British Steel - interim executives, materials and furnace futures

Business Secretary signs off appointments, raw materials paid for.

Tonight, we wrap up the latest British Steel news as two interim executives are announced, both are long-term British Steel employees. Allan Bell is Interim Chief Executive Officer and Lisa Coulson as Interim Chief Commercial Officer.

In interviews today, Deputy Prime Minister Angela Rayner said that the raw materials needed to keep British Steel's Scunthorpe plant operating have been paid for, although she gave no indication of arrival time.

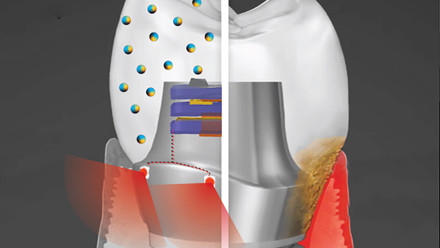

Professor David Dye, Professor of Metallurgy, Imperial College London, notes that keeping the blast furnace up to temperature is a delicate balance. ‘It’s a tricky exercise to change the conditions it’s operating in; it’s not like throwing a switch. You can (and by all reports they are) run it at a lowered rate, but there are limits.

‘It is possible of course to relight a blast furnace. Campaign lifetimes have increased over the decades and are now 20+ years.

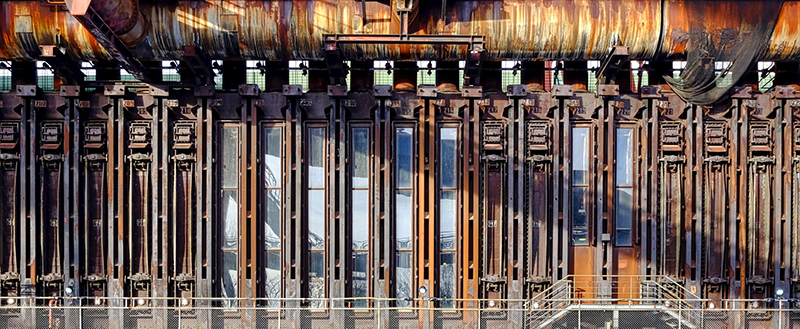

'Typically, a big integrated steelworks has/had several blast furnaces (four at Scunthorpe) so that one could be down for an 18-month refurbishment cycle, e.g. in the 1960s, they might have been under 10 years in duration and so the refurbishment team would be semi-continuously cycling around them.

'These life extensions to plants are part of why a steelworks now employs so few people compared to the 1970s or 1980s, and indeed a lot of the plant upgrades are now contracted out to the equipment manufacturers. So relight is usually accompanied by a £200mln+ refurbishment, replacement of the refractory brick and so on.

‘That is, anything is possible if you are willing to spend enough money and time, but furloughing a blast furnace for months or a year isn’t normally considered a viable response to swing in the market price of steel, and this is why oversupply and dumping are such a big issue for the industry (similar for aluminium pot lines); you end up having to produce at a loss.’

Professor Vlad Mykhnenko, Professor of Geography and Political Economy at the University of Oxford, sees the government move as positive. ‘The progressing nationalisation of the British steel industry will have a tremendous impact upon the UK’s as well as wider European net-zero transition plans.

‘The steel industry is responsible for around 7% to 8% of the global CO2 emissions; hence the decarbonisation of this sector plays a key role in achieving the UK’s as well as the European Union’s ambitious climate goals. Both the UK and the EU have committed to moving towards low- and zero-emission steel, also known as green steel.’

He notes that the upcoming CBAM legislation from the EU and UK will ‘eventually make traditional carbon-intensive steel-making unprofitable. In this context, blast furnaces currently operating at the British Steel works in Scunthorpe, Lincolnshire, will have to be phased out.’