Boost to US rare-earth magnet supply chain

MP Materials has reached a milestone in restoring the US rare-earth magnet supply chain.

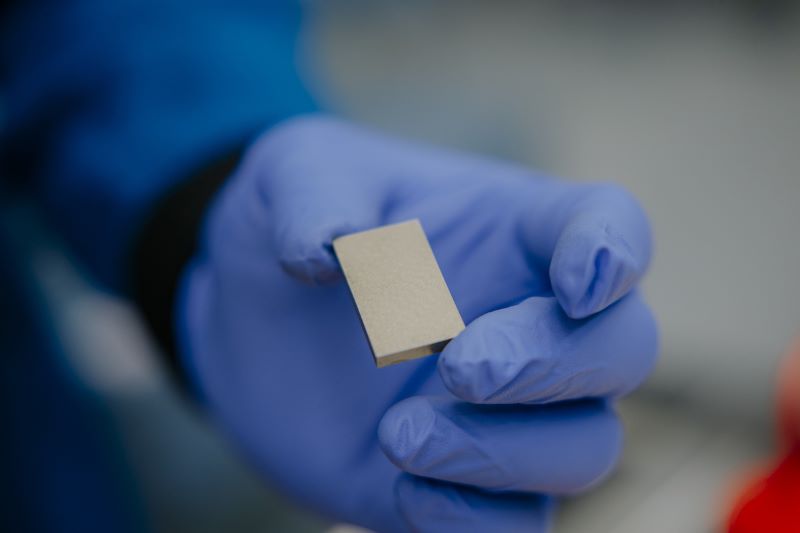

Its flagship Independence facility in Fort Worth, Texas, started commercial production of neodymium-praseodymium (NdPr) metal and trial production of automotive-grade, sintered neodymium-iron-boron (NdFeB) magnets.

This is in a move to re-establish a fully integrated, domestic supply chain for these critical components for the first time in decades.

NdFeB magnets – powerful and efficient permanent magnets – are essential components in vehicles, drones, robotics, electronics, and aerospace and defence systems.

Despite this key function, the US has relied almost entirely on foreign sources for these materials for decades.

Commercial NdPr metal production is already online and trial production of sintered magnets is underway.

Independence is poised to produce approximately 1,000t of finished NdFeB magnets per year, with a gradual production ramp beginning in late 2025.

The facility will supply magnets to General Motors and other manufacturers, sourcing its raw materials from Mountain Pass, MP Materials’ mine and processing facility in California.

‘With record-setting upstream and midstream production at Mountain Pass and both metal and magnet production underway at Independence, we have reached a significant turning point for MP and US competitiveness in a vital sector,’ James Litinsky, Founder, Chairman and CEO of MP Materials says.