Blasting rocks with lightning-like strikes

A high-voltage technology from the University of Queensland, Australia, smashes mining ore without grinding.

Project leader Dr Christian Antonio thinks the technology, currently being commercialised, could significantly reduce energy consumption and help decarbonise mining.

The High Voltage Pulse (HVP) discharges short pulses, like a lightning strike, to selectively break valuable mineralised ores while keeping barren rocks intact. By doing so, the researchers think the system can decrease processing time and increase energy efficiency. It is particularly suitable during grinding as it is said to reduce time and energy by around 30%.

The HVP technology is akin to ‘lightning attractors’, explains the team. The electrical energy automatically targets conductive mineral particles within a rock and breaks it up as it moves.

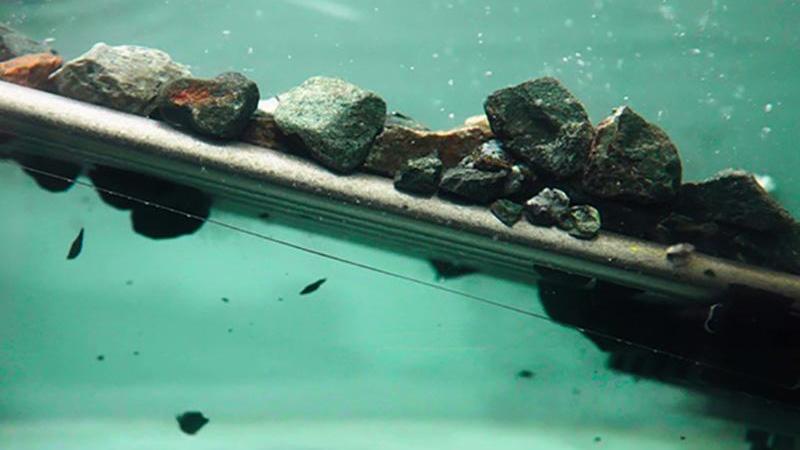

It works by electrifying a conventional mineral processing tool (called a grizzly) that sorts the rocks by size, so they can be simultaneously zapped while fragments fall through it.

The grizzly has parallel bars with a specific gap that smaller ores can fall through, while larger ores flow over the bars. When electrified, the mineralised particles are broken as they move across the bars. The system requires less than 5kWh/t, reports the team.

This high-grade stream then needs less energy to break up the minerals for downstream grinding, while low-grade or barren rock flow is separated and can be discarded. The current technology delivers up to 200kV to the electrodes.

The process occurs underwater, where the energy is released into the rocks in nanoseconds. “At these very quick release rates, the breakdown strength of the solids is less than the water, so the energy is directed to the solids, and the water essentially becomes an insulator,” says Antonio.

'The primary goal of our HVP process is not just to break rocks but to utilise the technology as a pretreatment method. While rock breakage will occur, the ores will also benefit from preconcentration, pre-weakening and improved liberation.' This is more efficient while exceeding the mining throughput requirement of 100t/h, he reflects.

The grinding results are from lab-scale equipment, using a batch system and a semi-continuous system that processes up to 1.5t/h.

While the HVP can reduce the rocks to micrometres, this requires significantly more energy than breaking them down to centimetre or millimetre sizes, he notes. The current system takes a feed up to 60mm, while the scaled-up unit will be able to take up to ~100mm in size, the team suggests.

Antonio is convinced the technology can be used for many mining types, although is currently being used for metalliferous ores such as copper and gold.

The team suggests it could also be used to recycle printed circuit boards or solar panels to separate metals from plastic or glass.

The Australian Government is now funding the scale-up to a pilot plant. In Phase 2, a 5-10t/h HVP will treat large quantities of ores.

Further advancements could include more efficient HPV generators and refined electrode designs.