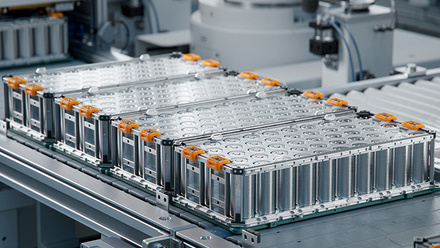

UK Battery Development Laboratory opens

The UK Battery Industrialisation Centre (UKBIC) says its facility enhances materials characterisation, cell analysis and forensic activities.

The 240m2 laboratory is open to all UKBIC customers and contains characterisation equipment for elemental analysis (ICP), electrode imaging and particle morphology (SEM/EDX), phase analysis for crystalline materials (XRD), thermal properties and thermal stability (TGA), carbon-based materials characterisation (Raman), and electrolyte characterisation (GC, NMR)

The Battery Development Laboratory (BDL) focuses on five key areas:

- Characterisation – for analysis including material properties such as morphology, crystal structure, elemental and material compositions

- Chemical and physical processing – for the preparation of samples for characterisation and the handling of more hazardous samples

- Forensics – equipped with both thermal and optical cameras for investigating cell failures and for the safe teardown of cells

- Electrochemistry – for advanced electrochemical analysis, including extended cycling and electrochemical impedance spectroscopy

- CT Scanner – for non-destructive analysis of cells to understand issues and potential failure modes without the need to physically teardown the cell

Richard LeCain, UKBIC’s Chief Technology Officer, believes the BDL will give customers a ‘steady flow of data’ on the route to commercialisation.

The BDL is part of a series of £74mln upgrades to the UKBIC, funded through the Faraday Battery Challenge (via UK Research and Innovation).

The UKBIC is a manufacturing battery development facility, helping UK businesses scale up and provide skills for the battery sector.