ABB launches 'Do More With Digital' campaign

ABB calls on companies to leverage advanced solutions to bridge digital gaps in the process industries.

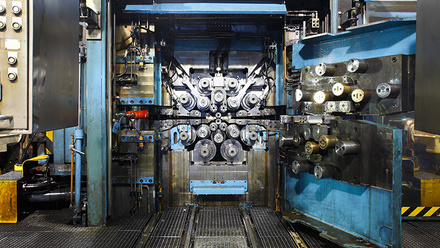

The firm draws on an expert team to deliver insights in pulp and paper, mining, metals, cement and other process industries.

The World Economic Forum reports that digital solutions can accelerate net-zero in high-emission industries, delivering up to 20% of the total reduction that the International Energy Agency says is needed by 2050.

'Adoption of advanced digital technologies is still much slower than one might expect in the process industries,' says Sanjit Shewale, Global Business Line Manager for Digital, ABB Process Industries.

'Customers are facing new challenges in proving and scaling up solutions that will drive real, transformative change. However, there are opportunities for all parties to use technologies to retain knowledge of processes in their business as people retire or move on in shorter timeframes than was typical in the past.

'Through co-creation, there is the chance to show more and do more for positive investment decisions that quickly result in unprecedented levels of energy management, efficiency, sustainability, safety and service.'

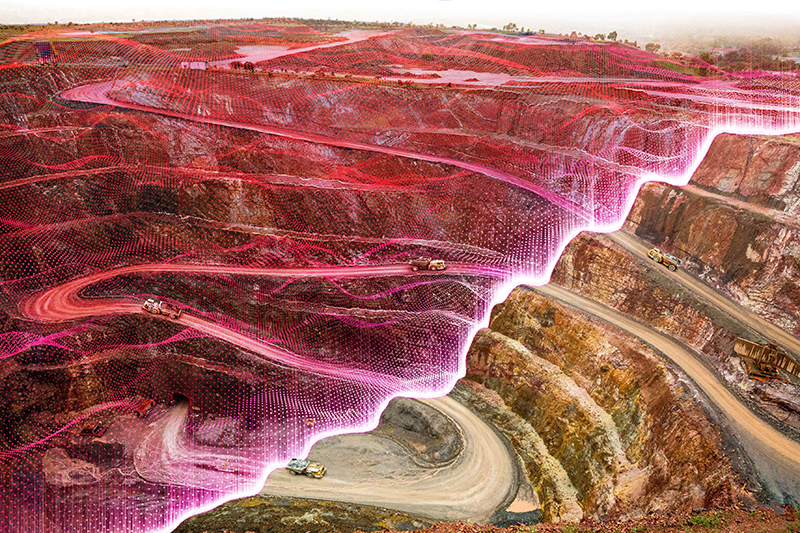

ABB cites the mining industry, where digitalisation is helping companies to address their most pressing challenges around environmental impact, safety, and economic volatility.

An example is Boliden's Aitik copper mine in Sweden. A digital twin of the grinding circuit, allowed them to test and optimise an advanced process control strategy in a virtual environment before implementation, resulting in reduced energy consumption and improved process stability.

'The mining industry is crucial to modern economic development, yet it faces significant challenges in areas like safety, productivity, and environmental impact,' says Max Luedtke, Global Business Line Manager, Mining, ABB Process Industries. 'By embracing advanced digital solutions, mining companies can unlock a new era of operational excellence and safety through remote monitoring, and even contribute to a more sustainable future through real-time data-driven decision making.'