A sodium battery that can withstand hundreds of charging cycles

One of the first prototypes using sodium in batteries that can be charged hundreds of times is being unveiled.

In the drive to create better batteries for a society that is more and more dependent on electronics, an organic sodium-based device has been on researchers’ radars for a while. Using sodium could be beneficial as it is said to be more conveniently and abundantly available, as well as affordable, compared with mining lithium.

Now, scientists at Imperial College London, UK, believe they have successfully created one of the first prototypes of a sodium-ion quick charging battery that can be charged and discharged hundreds of times without losing any capacity.

They claim to have overcome one of the main hurdles with replacing lithium with sodium – the size of the sodium ions, which are larger and therefore require a different anode material than graphite.

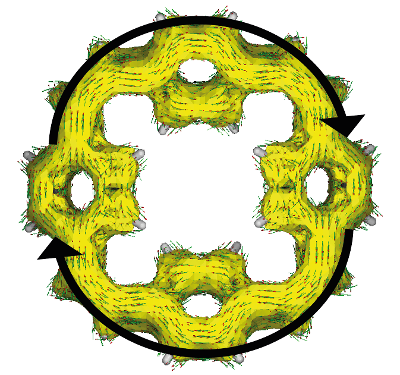

Dr Florian Glöcklhofer, Research Associate from the University’s Department of Chemistry, explains that their sodium-ion battery uses macrocyclic molecule paracyclophanetetraene as the electrode material. The macrocyclic molecule is synthesised in one step using readily available starting materials, terephthalaldehyde and triphenylphosphonium bromide.

However, it has mainly been chosen because of its shape, which Glöcklhofer compares to a pineapple ring or a disc, where the whole in the middle is the essential part.

‘No matter how densely the macrocycles are stacked in the electrode, there will always be space in the centre of these cyclic molecules that can be occupied by sodium ions when charging the battery. This helps to overcome the problem that sodium ions are larger than lithium ions,’ he states.

The current capacity of the macrocycles, Glöcklhofer explains, is ‘approximately 150mAh g−1 at a current density of 100mA g−1 in our testing set-up. This capacity needs to be further improved before it can be developed into a battery with performance parameters comparable to fully developed batteries’. He highlights that the strength of the current material is in the performance over several cycles and under fast charge and discharge conditions.

‘It is significantly more challenging to find suitable electrode materials for sodium-ion batteries than for lithium-ion batteries. Our development shows a new way of overcoming this issue. We are convinced that the introduced new concepts and ideas can spark exciting new developments in the field of organic battery electrodes,’ Glöcklhofer says.

He believes they can enhance capacity by improving the macrocycle’s structure. ‘Currently, each macrocycle can store two electrons, but we might be able to increase this to six or even eight electrons per macrocycle,’ Glöcklhofer adds. ‘However, while the capacity is certainly an important parameter, the cycling stability can be the more important parameter for some applications.’