3D-printed telecom devices herald weight reductions

A compound to 3D print lightweight telecommunication antennae and other connectivity devices has been developed in a US-Canadian collaboration.

The team from the University of British Columbia Okanagan and Drexel University have combined the 2D material MXene with nylon 12, also known as polyamide 12.

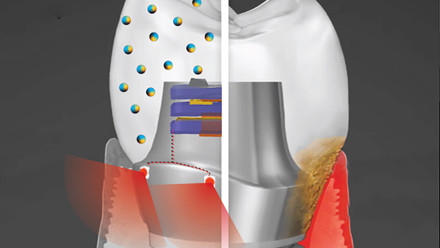

Waveguides are structures or pipes that direct sound and optical waves in communication devices or appliances such as microwaves. While they vary in size, they are usually made of metal for conductivity.

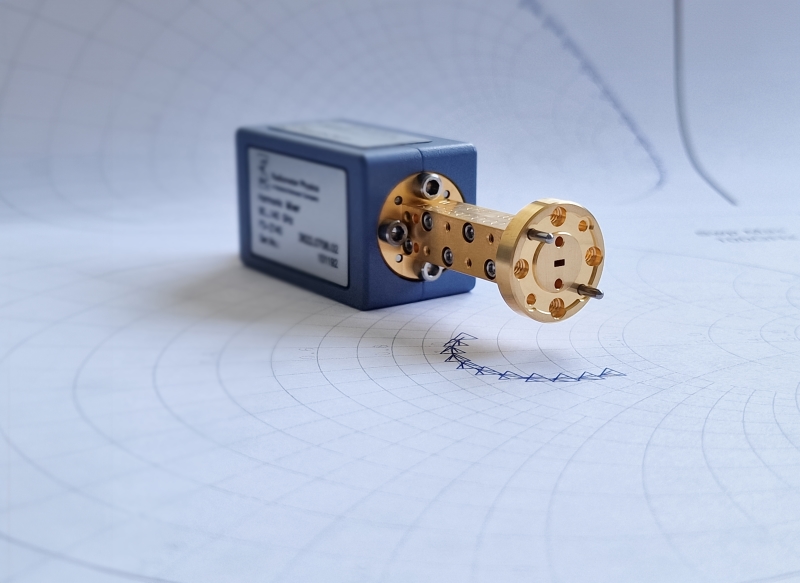

The team has now 3D printed components to perform like metal, but which they claim are lighter, less expensive and easy to build.

Their paper – MXene guides microwaves through 3D polymeric structures in Materials Today – notes a waveguiding functionality of 8-33GHz, covering low-Earth orbit frequencies, with a power-handling capability of up to 10dB and a transmission coefficient of 93%.

The paper notes that a single dip coating enables the polymer waveguide to perform only 2% below a metallic equivalent that is eight times heavier.

Dr Yury Gogotsi, Director of the A.J. Drexel Nanomaterials Institute, says MXenes are like nanometre-thin conductive flakes that can be dispersed in water-like clay, and applied with no additives to almost any surface.

'After drying in air, it can make polymer surfaces conductive. It’s like metallisation at room temperature, without melting or evaporating a metal, without vacuum or temperature,' Gogotsi notes.

Ti₃C₂Tx Mxene was chosen for its high electrical conductivity, solution processability, and potential for multifunctionality and performance tuning.

The 3D-printed plastic parts are dipped in colloidal MXene solution and dried at room temperature, according to Associate Professor Mohammad Zarifi at the University of British Columbia.

'We did a supplementary study to evaluate the effect of solution viscosity on the formation of coating layers. Our observation indicated that the more viscous solution was better coated on the surface of the nylon parts,' says Zarifi.

Integrating MXenes onto 3D-printed nylon-based parts creates a channel-like structure that is more efficient at guiding microwaves to frequency bands, say the researchers, who think the lightweight, additively manufactured component could impact the design of communications devices in aerospace and satellites.

Zarifi explains, 'The MXene nanomaterial forms an electrically conductive coating on the polymeric, non-conductive channel walls, resulting in a mirror-like reflection mechanism for microwaves. By setting the right geometry and size for the structure, these reflections can be utilised to guide microwaves through a hollow channel, from one point to the other.'

They have so far printed various microwave components, including resonators and twists, and plan to print radiating structures such as antennae.

Zarifi says they intend to study enhanced electrical conductivity and find ways to reduce the weight further through either different 3D-printing methods, or by using lower-density polymers. They also hope to make filaments of MXene and a polymer to 3D print the complete devices and remove the dip-coating step.