£13.7mln for projects harnessing digital technology for manufacturing

Projects include 3D printing at scale and using AI to improve steel production efficiency.

The Sustainable Smart Factory Competition, led by UKRI, has awarded funding designed to optimise the use of materials, reduce and reuse waste, or lower energy consumption to increase sustainability in production.

Among the 12 projects awarded funding today as part of the Made Smarter Innovation Challenge are:

- LEAD Factory, led by Photocentric - the first technology that will enable products to be 3D printed at scale using recycled materials

- WasteMap, led by Topolytics – using machine learning to develop a visual map of useful, reusable manufacturing products that can be extracted from our waste system

- Reducing Energy Consumption and Material Loss in Steel Production Using Predictive Machine Learning, led by Deep.Meta - using machine learning to boost sustainability in the production of steel by predicting where inefficiencies lie before they happen

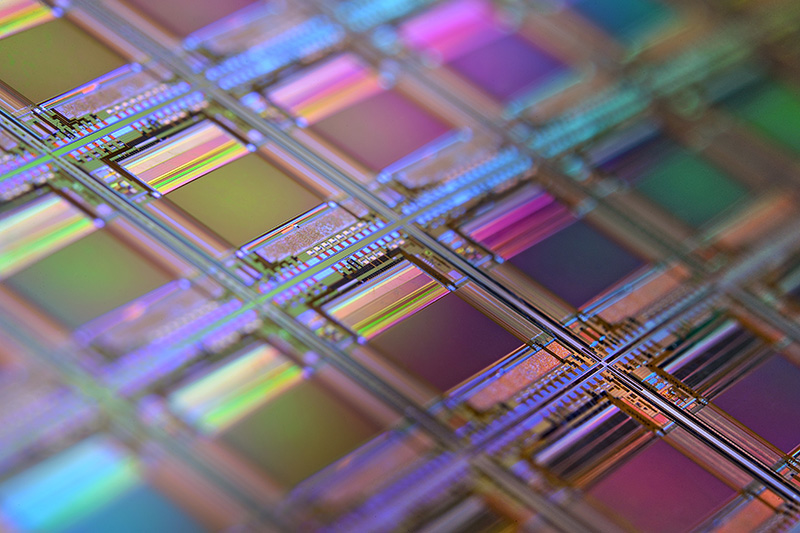

- INSPIRE by Pragmatic Semiconductor – tackling global semiconductor shortages by using AI to optimise manufacturing productivity and efficiency

Chris Needham, Innovation Lead in the Made Smarter Innovation Challenge says,’ Effective digital technologies can have a substantial impact on the manufacturing sector, bringing outdated, inefficient and unproductive products and processes up the standards needed for a net zero industry of the future. It’s clear from the wide range of applications we received just how far waste and energy issues extend across different industries.’