Past Young Persons' Lecture Competitions finalists' details.

2025 final - 8 May | The Armourers' Hall, London

Winner | Scotland

Hamish Dow

2nd Place | South West & South Wales

Samual Ngombe

3rd Place | South East

Emma Bryan

North West & North Wales

Sethupathi Rangaraj

Midlands

Amelia Tortell Milhano

North East

Ethan Ellis

Winner | Scotland

Hamish Dow

Dr Hamish Dow is a Research Associate at the University of Strathclyde’s Department of Civil and Environmental Engineering. His research investigates novel AI-based imaging methods for detecting and quantifying concrete structure defects. Hamish's lecture will explain how AI can be used for visual inspections, highlight innovative concrete inspection methods developed at the University of Strathclyde, and present real-world, Strathclyde-led, case studies demonstrating AI-driven inspection applications.

Lights, camera, action: Automated visual inspections of concrete structures

Early identification of defects in concrete structures is vital to ensuring their longevity and resilience. However, traditional visual inspections are expensive, inconsistent, labour-intensive, and dangerous.

Our invention, Adaptive Lighting for the Inspection of Concrete Structures (ALICS), is a new inspection platform: it is an automated, and robot-mountable concrete visual inspection device that uses lighting and artificial intelligence to detect, classify, quantify, and monitor concrete defects with unprecedented speed, accuracy, and precision.

ALICS’s lighting-enhanced inspection method enables fast, targeted concrete defect repair and monitoring of concrete infrastructure, extending asset lifespans and reducing carbon-intensive new-build construction.

This presentation will showcase ALICS’s lighting-enhanced inspection method and concrete defect detection abilities. Results from on-site deployment will also be presented, validating ALICS’s methods in a real-world environment.

2nd Place | South West & South Wales

Samual Ngombe

Samual is a third-year EngD student at Swansea University, working on scaling up the commercial potential of next-generation perovskite solar cells. His presentation focuses on a game-changing solar technology developed by Power Roll, exploring how it works, why it matters and the powerful role solar energy can play in addressing our global energy challenges. With the world striving to meet Net Zero goals, Samual is determined to contribute to real-world solutions.

Aside from his research (which often means spending quality time in a cleanroom suit and hair net), Samual has done his fair share of American Football (both playing and coaching). He is a huge advocate for sustainable living and believe that access to clean energy should be universal, no matter the circumstances. Hopefully, he can not only share some insights but also alter your perspective on solar energy, showing how something as small as micro groove can have a big effect on the global democratisation of energy.

From grooves to grid: The next generation of solar technology

Power Roll has pioneered a fully R2R production process based on their novel architecture. This involves embossing microgrooves onto a flexible substrate, followed by directional deposition of electrodes and charge transport layers on opposite faces of each groove. R2R perovskite deposition and encapsulation finish the PV modules in a highly scalable low-cost manufacturing process.

3rd Place | South East

Emma Bryan

Emma is a PhD student in the Materials department at Imperial College London, researching molecular semiconductors. These materials are enabling advances in the field of organic electronics, from more flexible, lightweight and wearable devices to brighter, more energy efficient displays and solar cells. Her PhD focuses on the characterisation of these next-generation materials, understanding their structure and conductive properties, particularly using scanning probe methods which is the subject of her presentation!

Outside her PhD Emma enjoys creative writing, painting and music. She believes there’s a big overlap between art and science, so loves anything that explores this space. She also enjoys designing outreach activities and volunteering to help inspire the next generation of scientists and engineers.

An ode to conductive probes

Atomic Force Microscopy (AFM) is a fantastic technique for characterising nanoscale properties. AFMs are like a miniature record players: an ultra-sharp ‘tip’ scans over a sample, generating a 3D map of the nano-bumps and grooves. The resolution is so good that, if you’re super careful, you can image individual chemical bonds. AFM is non-destructive and requires no special preparation, which is particularly useful for soft materials that degrade in electron beams. Advanced AFM modes can unlock new nanoscale functional information about materials, which is the basis of my research.

By applying a voltage through a conductive AFM probe, we can excite vibrations in piezoelectric materials which can be measured using the highly sensitive detector. I use piezoresponse force microscopy to create nanoscale patterns in polymers, which are useful in next-generation data storage, and can be used to locally reorient molecular layers. This opens the door to tailored flexible electronic devices.

North West & North Wales

Sethupathi Rangaraj

Sethupathi is a second-year PhD student and a Dean’s Doctoral Scholar in Materials Science (Imaging and Characterization) at the University of Manchester. His research focuses on understanding the failure mechanisms of additively manufactured alloys (AlSi10Mg) using advanced characterization techniques such as 3D Electron Backscatter Diffraction (EBSD) and X-ray Computed Tomography (X-ray CT). He is also driving his research toward real-world impact by collaborating with industries to maximize the value of his PhD.

Apart from research, he is passionate about science communication and outreach. As a Discover Materials Ambassador, he engages with young students through inspiring workshops and hands-on experiments to promote awareness and excitement about materials science. In his free time, he enjoys archery, bouldering, and cooking.

Why can additively manufactured materials fail differently in different directions? Investigating the role of defects

Additive manufacturing (AM) offers enhanced control over material properties and design flexibility, with Laser Powder Bed Fusion (LPBF) enabling the creation of alloys with finely tuned characteristics and minimal material waste. This approach is more sustainable than traditional manufacturing, reducing material consumption and emissions. However, LPBF is prone to defects like lack of fusion and porosity, which can negatively impact mechanical performance. These defects vary in orientation, affecting material behaviour.

Understanding how defect orientation affects mechanical properties is key to improving AM reliability. X-ray CT (Computed Tomography) offers detailed insights into the structure and distribution of defects. This study investigates how defect orientation in LPBF alloys influences mechanical failure, using X-ray CT to assess defect impact. The findings aim to optimize parameters, enhance material quality, and contribute to more reliable and sustainable AM technologies.

Midlands

Amelia Tortell Milhano

Amelia is a Materials Scientist at 4D Medicine Ltd., a startup based at MediCity in Nottingham, where she has worked since graduating with an MEng from the University of Oxford. Her role involves preparing and characterising degradable polymer systems, and 3D printing these materials into a range of commercial medical devices. Amelia grew up in Switzerland and is a dual citizen of Portugal and New Zealand but has found her home in the East Midlands.

Delving into the 4th dimension: 3D printing resorbable polymers for regenerative medicine

In recent years, advancements in additive manufacturing (AM) have unearthed 3D printing as a manufacturing process in its own right. Its inherent design freedom allows for the creation of customisable, complex, small-scale geometries. Innovation in materials chemistry has led to the synthesis of new bioresorbable polymers. The advantages of resorbable medical materials are vast, and their development promises endless novel device concepts.

AM has long been used to produce inorganic medical devices. However, it is not until recently that successful 3D printing of organic, biodegradable materials for medical devices has been accomplished. At 4D Medicine, Digital Light Processing, is used to 3D print a range of devices from a biodegradable resin with tuneable mechanical properties.

In this talk, I will explore the motivation behind combining these two emerging technologies, the materials challenges unearthed in doing so, and the opportunities that this creates for the healthcare industry.

North East

Ethan Ellis

Ethan Ellis is a second-year materials science degree apprentice at Lucideon with the University of Derby. His work involves projects centered around materials development in aerospace and defence applications on advanced ceramics. One self-led project that Ethan is developing is a new ultra-high temperature ceramics processing method. However, Ethan's interest in weird and wonderful materials has inspired him to give this lecture on Synthetic spider silk.

Synthetic spider silk: A sustainable future for high-performance materials

Spider silk, renowned for its strength-to-weight ratio surpassing steel, has been challenging to mass-produce because of its complexity. The material's unique structure allows for simultaneous toughness and ductility, setting it apart from traditional materials. Recent discoveries in the production of this material, through genetic engineering of microbes and silkworms, allow for its implementation into real-world applications. This literature review explored the mechanisms, processing, and future applications of synthetic spider silk. The findings show synthetic spider silk demonstrates exceptional mechanical properties of 35-50% elongation and 5GPa tensile strength while remaining biodegradable and biocompatible. Sustainable production methods such as synthesizing proteins at body temperature. These developments position synthetic spider silk as a promising biomaterial with potential applications in medical technology, advanced textiles, and high-performance engineering solutions.

2024 final - 15 May | The Armourers' Hall, London

2024 final - 15 May | The Armourers' Hall, London

Winner | North East

Emilia Russell

2nd place | South East

Philipp Schulz

3rd place | Midlands

Hannah Hilton-Tapp

Scotland

Nick Mappin

North West & North Wales

Rajinth Shanthar

South West & South Wales

Tom Jessel

Winner | North East

Emilia Russell

Emilia Russell is a 2nd year PhD student in the Department of Engineering at Durham University, currently investigating the impacts of mechanical strain on the electrical properties of 2-dimensional semiconductors. In her free time, she enjoys sailing and organising seminars from industry speakers with the Women’s Engineering Society at Durham.

Why strained semiconductors are like crinkle-cut crisps

When applying strain to 2-dimensional transition metal dichalcogenides, it has been observed that the bandgap changes. The bandgap is the potential difference between the highest energy bounded (immobile) electrons and the delocalised (mobile) electrons.

Crinkle cut crisps taste better because they hold more salt, crinkle cut semiconductors insulate better because they hold more electrons.

This effect could be exploited in the next generation of synthetic skin. It could also be used to design flexible acetylene detectors to monitor food expiration, reducing food waste. To date, the relationship between mechanical strain and electronic properties has predominantly been shown through computational modelling. This research focuses on overcoming the issues that have hindered the realisation of these devices, such that the effects of strain on other semiconductor properties can be investigated. In turn, this will lead to a better understanding of the electrostatics and charge transport of these novel 2-D materials.

2nd place | South East

Philipp Schulz

Philipp is a second-year PhD student at University College London (UCL) investigating the environmental degradation that nickel-base superalloys may face in hydrogen combustion jet engine environments. At UCL, he is also a postgraduate research student representative, as well as committee member of the Mechanical Engineering Researchers’ Society.

In his free time, he enjoys road cycling and reading.

Hydrogen-related degradation of nickel-base superalloys exposed to hydrogen combustion environments

Hydrogen-powered combustion systems are seen as a highly feasible option to decarbonise aviation, by and beyond 2050. It is therefore critical to understand if H-induced degradation, such as hydrogen embrittlement, could happen in high-temperature alloys used inside the combustion chamber. While H embrittlement is well documented in literature for near room-temperature applications, it is not clear how H interacts with high-temperature materials during H combustion.

This presentation aims to give a comprehensive overview of the challenges imposed on nickel-base superalloys by hydrogen environments. Additionally, the differences between past literature data regarding hydrogen-related degradation of Ni-base superalloys and their future application in hydrogen combustion environments will be highlighted. Lastly, insights will be given into current and future experimental studies to tackle these challenges and facilitate the introduction of carbon-free aviation.

3rd place | Midlands

Hannah Hilton-Tapp

Hannah is a third-year PhD student at the University of Leicester, working in the Centre for Sustainable Materials Processing and Space Park Leicester, under the supervision of Dr Ramy Mesalam. Her research interests include surface finishing of materials, electrodeposition of nanocomposites and the production of thermoelectric devices for use in Radioisotope Thermoelectric Generators (RTGs). She also sits on the Advisory Council for IOM3 as a postgraduate student representative.

Production of copper nanocomposite coatings via a novel pulse-reverse plating technique

The development of the process to produce Metal Matrix Nanocomposite (MMNC) coatings provides opportunity for the enhancement of material properties. As the demand of materials increase, the properties of these materials must progress with them. Equally, if the properties of materials improve, technology can progress quicker. Copper is of particular importance in industry due to its high thermal and electrical conductivity at room temperature, however it is a relatively soft, malleable, and prone to oxidation metal.

Incorporating nanoparticles into the copper matrix can improve the properties of the coatings, without significantly diminishing others. The utilisation of Pulse Reverse Plating (PRP) in the production of MMNCs has been explored over the years but this work looks to utilise the anodic pulse and anionic surfactant to increase particle content. Resulting composition and properties were determined and characterised.

Scotland

Nick Mappin

Nick is a fifth-year Integrated Master’s student at the University of St Andrews, with a particular focus on igneous petrology and ore geology. His research investigates a nepheline syenite deposit in the north of Norway, which is mined for nepheline and feldspar, for use in glass and ceramics. He is establishing what the controlling factors are on the ore quality and how and why the ore spatially varies throughout the deposit.

Fluid interaction in nepheline syenite, Stjernøya, Norway, and the implication for ore quality

The Nabarren nepheline syenite deposit is an intrusive body in the south of the Lillebukt Alkaline Complex, Norway. It comprises two predominant, syenite types, subdivided based on the accessory mafic mineralogy: biotite- and pyroxene-nepheline syenite. Sibelco operates an open pit and underground mine, exploiting nepheline and feldspar, for use in glass, ceramics, and paint fillers. Past studies conclude that biotite-bearing nepheline syenite has a reduced ore quality, however, the cause of the degradation is unknown. Contaminated carbonatite dykes are heterogeneously distributed throughout the deposit. Field evidence, cathodoluminescence, and petrography reveal a strong mineralogical alteration and ore quality reduction surrounding the dykes. Metasomatism or magmatic interaction between carbonatite and syenite is interpreted to cause this change. This presentation explores the processes liable for the ore quality variation and how ore beneficiation and mine operations can be enhanced.

North West & North Wales

Rajinth Shanthar

Rajinth is a second-year PhD student from the Department of Materials, The University of Manchester, under the supervision of Dr Chamil Abeykoon, Dr Robert Prosser and Prof Prasad Potluri. His research is focused on simulating the flow of a liquid through a multiscale porous media, specifically the flow of polymeric resins across carbon and glass fibre fabrics.

He is trying to introduce the complex relationships observed in the physical world between the resin flow and parameters such as resin pressure, flow rate, temperature, and fabric properties into the numerical domain. Rajinth’s research spans a broad range of topics such as Computational Fluid Dynamics (CFD), polymer rheology, composite manufacturing, and process optimisation.

Optimised composite manufacturing using Resin Transfer Moulding

Composite materials have become a staple in modern engineering. For example, Fibre Reinforced Plastics (FRP) are widely used in industries such as aerospace and automotive thanks to their high strength-to-weight ratio. The reinforcement can be synthetic fibres such as carbon and glass, whereas the matrix is typically a thermosetting plastic. Resin Transfer Moulding (RTM) is a method of fabricating FRP parts, capable of achieving an excellent surface finish and high rates of production.

Here, the reinforcement fabric is placed within a rigid mould, injected with the liquid matrix material and finally heat cured. To optimise the RTM process and to ensure that the parts produced have high quality and minimum defects, Computational Fluid Dynamic (CFD) flow simulations can be used as a cost-effective approach. However, these CFD models need to sufficiently capture all the flow complexities associated with the RTM process to yield accurate and useful results.

South West & South Wales

Tom Jessel

Tom graduated from Cardiff University in 2021 with a First Class Honours degree in Mechanical Engineering. Currently he is a third-year PhD student at Cardiff University, working in conjunction with Renishaw plc.

His research focuses on tool condition monitoring and evaluation of diamond-coated tools, with the aim of replacing tools when necessary and not at periodic intervals. The research project has a focus on the utilisation of acoustic emission (AE) and applications of advanced signal processing techniques to determine remaining tool life, thereby reducing waste and the costs associated with discarding tools prematurely.

Outside of research, Tom enjoys climbing on the sea-cliffs or quarries of South Wales.

The potential of unsupervised Machine Learning techniques for Tool Condition Monitoring of Diamond-Coated Burrs

Within manufacturing there is a growing need for autonomous Tool Condition Monitoring (TCM) systems, with the ability to predict tool wear and failure. This need is increased, when using specialised tools such as Diamond-Coated Burrs (DCBs) for grinding high strength ceramics or glass, in which the random nature of the tool, inconsistent manufacturing methods and high wear rates create large variance in tool life. This unpredictable nature leads to a significant fraction of a DCB tool's life being underutilised due to premature replacement.

Acoustic Emission (AE) in conjunction with Machine Learning (ML) models present a possible, on-machine monitoring technique, which could be used as a prediction method for DCB wear. The unsupervised training of autoencoders, shows promise in predicting DCB wear based solely on components of detected AE, potentially allowing for the continuous monitoring of individual tools.

2023 final - 3 May | The Armourers' Hall, London

2023 final - 3 May | The Armourers' Hall, London

2023 final - 3 May | The Armourers' Hall, London

Winner - South East

Georgina Burgoyne Morris

2nd place - Midlands

Toby Reid

3rd place - South West & South Wales

Phil Smith

North West & North Wales

Thomas Hughes

North East

Henry Saunders

Scotland

Gillean Brook

Winner - South East

Georgina Burgoyne Morris

Georgie is a first year PhD student at the Department of Materials Science & Metallurgy at the University of Cambridge, where she stayed having completed her undergraduate degree in Natural Sciences, specialising in Materials Science. Her research, within the Photoactive Materials group, surrounds the development of self-healing polymeric hosts for triplet-triplet annihilation upconversion – a process by which the efficiency of solar cells could be boosted through the ability to usefully harvest sub-bandgap photons.

When she’s not in the lab, Georgie enjoys cooking, playing music, and going to pub quizzes.

Stimuli-responsive polymers as self-healing materials

The ability to autonomously repair damage can lead to significant improvements in lifetime and recyclability of polymeric materials, reducing both waste and production costs. This may be achieved either extrinsically, through the release of healing agents encapsulated in the polymer matrix, or intrinsically, as a result of dynamic interactions between the polymer chains themselves. The latter systems have the advantage that their healing ability is not reliant upon the presence of a secondary reactive species, giving potential to repair more extensive or repeated damage.

This talk will discuss how, through tuning their chemistry, polymers can be made to intrinsically self-heal under ambient conditions, or in response to external stimuli such as heat or light. It will also explore the variety of applications for these materials, from healable protective coatings to recyclable thermoset resins.

2nd place - Midlands

Toby Reid

Toby is a Non-Metallic Materials Engineer at Rolls-Royce Aerospace, specialising in elastomeric, sealing, and composite materials where he focuses on operational support for the delivery of Roll-Royce Civil engines as well as research and development into future sealing solutions for the next generation of Aerospace technologies.

Prior to this he spent 5 years at Loughborough University where he did a Master’s degree in Materials Engineering with specialisation and research into novel elastomer nanomaterial composites. While at university, he spent a year in industry researching and prototyping new materials for Parker Meggitt Aerospace where he developed a novel patent pending elastomer composite material with unique fireproof properties.

Outside of work Toby enjoys multiple sporting activities including rowing, cycling, sailing, and running alongside hobbies like woodworking and photography.

Row row row your boat: A look at the history and materials used in high performance rowing boats

Rowing has come a long way, as one of the oldest sports in the world starting as far back as 3000BC, to London water taxis racing along the Thames in the 1900s through to the elite level of the modern Olympic games. Rowing has seen some of the most dramatic changes in materials composition, development, testing and modelling as any sport or industry in modern times.

From master carpenters constructing long ships through to the first composite boats made from papier-mâché in 1870 and beyond into the high-performance aerospace grade composites and metals used in modern racing shells today. In a sport where medals are won and lost my millimetres, materials have played a crucial role as athletes and manufactures look to maximise all aspects of performance.

This presentation will look at the past, present and future of materials, the development of new manufacturing methods and how materials can make a boat the length of a bus carrying over 1 tonne of rowers weigh less than 100kg.

3rd place - South West & South Wales

Phil Smith

Phil is a third year PhD student studying Physics and Materials Science at the University of Bristol. He completed his undergraduate chemistry degree at the University of Plymouth, where he worked on biofuels as a solution to reducing greenhouse gas emissions. Phil moved to Bristol to pursue his interests in reaching Net Zero by researching nuclear fuels and how they may be improved. During his studies, Phil has been thoroughly involved in his community, holding many representative positions and highlighting financial challenges faced by PGRs through independent research. He has been able to improve the understanding of peers, academics and executives, through a series of conversations and talks.

Outside of research, Phil enjoys football, surfing and music. Regularly playing live music to audiences throughout the City of Bristol.

Improving Advanced Nuclear Fuel

Improving advanced technology fuels (ATF) can be an important step to achieving a cost-effective, long-term future of carbon free energy. Uranium mononitride, offers improvements in thermal conductivity and fissile density when compared with UO2 fuel, but has been shown to degrade faster in air and water.

Previous research with thin film samples at the University of Bristol, found that UN is more resistant to corrosion by hydrogen peroxide, which simulates radiolytic conditions of a fission reactor, and this presented work considers how a metal dopant may prolong corrosion further. However, it was found when analysed by X-ray Diffraction (XRD) that the addition of niobium, as a dopant into the solid solution of UN, caused a faster shrinking of the crystal lattice than expected.

This talk will cover the synthesis of niobium doped UN and discuss the possible reasons for reduced lattice parameters, and the ways to explore the hypotheses.

North West & North Wales

Thomas Hughes

Thomas is currently a PhD student at Manchester University on the AMS CDT working on in situ testing for fusion materials. He's working with the UKAEA and STEP to design and use a test rig to simulate fusion environments and look at synergistic effects of radiation damage, tensile testing, heat loads, irradiation creep etc. He likes trying to make problems as simple as possible, as trying to explain what he does to anyone is like speaking gibberish!

His presentation will try break down the problems fusion materials scientists face and how to deal with them, hopefully you'll find it as interesting as he does.

Materials Design for Nuclear Fusion

Nuclear fusion contains one of the most hostile environments for any material to face – high heat, load, and irradiation in an electromagnetic condition. The choice of materials to withstand such an environment is a key discussion, and perhaps the main hurdle to overcome if fusion is to progress. This short lecture will focus on the material challenges faced, design choices to overcome these challenges with an aim to provide a background on first wall design for Tokamak style reactors.

Work will focus on key components like divertor design in ITER and similar reactors. This will be supplemented with the PhD work of simulating this environment outside of a reactor with in-situ testing for synergistic effects.

North East

Henry Saunders

Henry is a first year PhD student researching into metal additive manufacturing (AM) at the University of Sheffield’s Henry Royce Institute. First drawn to the field of AM during his Master’s research project, utilising the technology to manufacture a rocket engine in a bid to be the first student team in the UK to build and test a liquid rocket engine.

During the project, I encountered a problem, the defect concentration in my additively manufactured parts was varying based on the geometry of the part I was building. Coincidently two of the postdocs in my research group were working on a solution for the problem that I had encountered. Recognising the commercial potential of this solution I turned down the job offer I had with an AM start up and set about following my ambitions to build my own.

Outside of his research and entrepreneurial activities, Henry enjoys running and climbing, making the most of the nearby Peak District.

Programmable microstructures: Unleashing the potential of engineering alloys with metal additive manufacturing

As we strive towards achieving our net zero targets, optimising the utilisation of engineering materials is crucial. By having control over the grain structure of metals, we can enhance the performance of parts in service, leading to lighter components for the electric aircraft of the future, as well as maximising the efficient use of non-renewable metal resources. The grain structure of a metal forms the basis for its mechanical properties, making it an integral aspect in the design and production of metal components.

Additive manufacturing, also known as 3D printing, is a process of making three-dimensional solid objects from a digital model by adding material layer by layer. By varying the parameters of our heat source, we can change the thermal cycle experienced by the material and ‘programme’ different grain structures into different locations.

Scotland

Gillean Brook

Data Mining: How Machine Learning is Shaping Geology

In this lecture I will explore how machine learning already has, and will continue to, change the field with case studies from the worlds of mining, hydrothermal, and research geology. I will attempt to demystify and explain the core concepts of machine learning and inspire fellow geologists in the audience to consider the applications of this exiting technology to their own projects.

*Gillean did not compete in the 2022 UK final.

2022 YPLC final - 4 May | The Armourers' Hall, London

2022 YPLC final - 4 May | The Armourers' Hall, London

Winner - North East

Lauren Eggleton

2nd place - Midlands

Anna Tholen

3rd place - South East

Ivan Grega

North West & North Wales

Katherine Nelms

South West & South Wales

Angus Siberry

Scotland

Grace Nielson

Winner - North East

Lauren Eggleton

Lauren is a second year PhD student in the Materials Science and Engineering Department at The University of Sheffield. She developed a passion for research during her Masters in Materials Science and Engineering, which specialised in biomaterials. During this time, she undertook a year in industry at Philips Research UK, working in oral healthcare on whitening and hypersensitivity. Upon returning, she channelled her love for research and nature into her master’s project on snail and slug locomotion in the Natural Materials Group, and has never looked back. Her EPSRC funded PhD focuses on understanding and bridging the gap between structure and function in snail and slug mucus.

Within the department and faculty, she is an active member of the postgraduate research community: supporting fellow students as part of the postgraduate research committee, helping teach undergraduates, and sharing research stories over arts and crafts lunches. Outside of the lab, she is a keen communicator and advocate for inclusion and diversity in STEM subjects, volunteering for outreach programmes and school events at both the local and national level. Through her work with the Bioladies Network and Natural Materials Association, she hopes to inspire people across all ages and backgrounds to discover the scientific wonders found in nature.

In her free time, Lauren enjoys exploring the Peak District, medieval re-enactment and has recently taken up ice skating. Though she can often be found at home curled up with a good book and her two cats.

A sticky situation: The contradictory material properties of snail mucus

Nature has evolved a vast range of 'smart' materials and is currently an untapped resource for novel biomedical and engineering applications. A surprising example is snail mucus. Embodying two contradictory properties, adhesion and lubrication, this material can switch seamlessly between them whenever the functional need arises. But how does it do this and can we replicate it?

In the search to understand these unusual flow properties, our creation of a snail locomotion translation device demonstrates how a more holistic approach to analysing natural materials can reveal more about their true nature. Discovering that like many industrial materials, snail mucus crystallises, but controlling this is via an elegant means of changing its salt concentration. Showing that we can find inspiration for tomorrow's advanced materials everywhere, even at the bottom of our garden.

2nd place - Midlands

Anna Tholen

Anna is a final year PhD student studying across the Materials School and the Wolfson School of Mechanical, Electrical and Manufacturing Engineering at Loughborough University. Her PhD, funded by the Engineering and Physical Sciences Research Council and Renishaw Plc, looks to improve the metallurgy of tool steel components when fabricated by laser additive manufacturing.

Prior to her PhD, Anna completed an undergraduate degree in Product Design Engineering at Loughborough University, which involved three years of study and a year in industry at Unilever, procuring injection moulds internationally. As part of her undergraduate degree she completed an individual research project investigating the use of laser surface patterning of bacterial cellulose for peripheral nerve recovery applications, which sparked her interest in laser processing and materials science, ultimately leading to her career in research. Alongside her PhD, Anna is passionate about promoting STEM subjects and proudly takes part in outreach activities within schools and universities to promote engineering to young people of all ages.

Outside of academia, Anna enjoys trail running in the Lake District, taking her dog Basil on long walks, and playing the flute and piccolo.

Effects of local thermal history on H13 tool steel components fabricated by laser powder bed fusion additive manufacturing

Hot work tool steels possess excellent wear resistance due to a microstructure of tempered martensite and hard carbides, making them suitable for manufacturing components that must withstand elevated temperatures for sustained periods of time. Laser powder bed fusion (LPBF) additive manufacturing (AM) is a promising fabrication process for hot work tool steels. The mitigation of subtractive processing means a component does not need to be machined in an annealed state and undergo post process hardening to achieve its characteristics for tooling applications.

However, a consequence of the rapid, cyclical heating and cooling during LPBF AM results in residual stress accumulation in the fabricated part, causing catastrophic defect formation. Hot work tool steel alloys are particularly sensitive due to the compromises in microstructural evolution. This research investigates local microstructural evolution in H13 components fabricated by LPBF AM and its links to localised mechanical properties and susceptibility to crack formation.

3rd place - South East

Ivan Grega

Ivan is a first year PhD at the Department of Engineering, University of Cambridge. He completed his undergraduate degree (2021) with a Master’s in Mechanical and Aerospace Engineering, receiving the Sir George Nelson Prize in Applied Mechanics and was awarded the Ashby PhD Scholarship to continue to study in Cambridge. His current research focuses on developing experimental approaches such as self-assembly as well as computational techniques such as deep learning to discover architected materials with unprecedented properties by optimising their topologies. His interest in this topic was ignited during his undergraduate research internship (SURF) at Professor Julia Greer’s lab at Caltech, where he learned that it is possible to make materials with the density of water but the strength and toughness of steel. This experience, together with the industrial perspective gained during his internship at Siemens, motivated his hunt for future technological possibilities of these materials such as reversible energy absorption and integrated functionality. This propelled him to work with Professor Vikram Deshpande on developing scalable self-assembly process for opal crystals which could form the basis of efficient fast-charging batteries.

As a core philosophy, Ivan believes in discussion and dissemination of ideas with colleagues and others. He supervises undergraduate courses in materials and solid mechanics. While not absorbed in research, he likes to tinker with electronics, model planes and fulfils his passion as an amateur glider pilot. He plays ice hockey for Cambridge Blues and enjoys swimming and cycling.

Scalable manufacture of inverse opal metamaterials

Reducing energy consumption is shifting the focus to renewables, and the key intermediary in this energy revolution are batteries. Batteries are reaching their limits in terms of current density. In order to keep increasing the power density, electrodes with high surface-to-volume ratio are needed. Metamaterials with a micro-scale architecture achieve this, and inverse opal metamaterials are prime candidates due to their manufacturing scalability. Here we investigate the mechanics of self-assembly process of dry spherical particles which will serve as a template for scalable inverse opal manufacture. We elucidate the factors which govern the assembly process including the crucial role of gravity. Based on these insights, we design seeding templates which enable the creation of stable close-packed single crystals as well as metastable non-close-packed geometries. These findings open up new possibilities not only for battery electrodes, but also for photonic and structural applications.

North West & North Wales

Katherine Nelms

Kat is a first year international PhD student studying materials science at the University of Manchester. She was awarded the President's Scholar award and studies under Professor Phil Withers. She completed her undergraduate degree in materials engineering at Cornell University with a minor in chemistry. Kat was drawn to materials because it is inherently interdisciplinary; she found her niche in polymer composites and greatly enjoys that composites research combines both mechanics and chemistry. During her undergraduate degree, Kat interned for The Aerospace Corporation in El Segundo, CA working at their Space Materials Laboratory. She also researched under former NASA CTO Mason Pech at Cornell's Space Systems Design Studio. In both positions, Kat's work emphasized composite materials for spacecraft. Kat's passion for space exploration was invigorated by solving challenging problems imposed by the unique environment of space; she then stayed at Cornell for her Master's in Aerospace where she took courses in astrodynamics, control theory, and space systems design.

Outside of research, Kat plays water polo and lifts weights (often to the soundtrack of 80's and 2010's dance music). She also dabbles in odd sports such as pole dancing and trampoline. When not doing sports, she can be found collecting houseplants and bullet journaling. Though she misses the Los Angeles sunshine, Kat has loved travelling the UK during her weekends and deciphering different British accents.

Effect of fiber microstructure on kinking in unidirectional carbon fiber reinforced composites images in real time under axial compression

It is well known that fiber-reinforced polymer composites (FRPs) undergo micro buckling, then catastrophic failure by kinking when loaded under compression. The aim of this project is to use x-ray computed tomography (CT) to investigate kink band initiation and propagation. CT scans of FRPs confirmed that kinking is planar in nature and were used to visualize the damage modes in 3D for the first time. Another key study used in-situ synchrotron radiography at 10kHz to show that complete propagation occurs within 1.2 ms and revealed the previously debated initiation mechanism. Recent efforts focus on fiber movement during compression and confirm that misalignment contributes significantly to kink initiation but does not play a key role in propagation. Moving forward, ultrafast in-situ synchrotron radiography (20-40kHz) will be used to investigate the role fiber waviness on both FRP kink initiation and propagation.

South West & South Wales

Angus Siberry

Angus is a final year Ph.D. Computational Nuclear Physics student at the University of Bristol. While at Bristol he obtained an MSc in Nuclear Science and Engineering following a BSc in Physics. Angus has been working on nuclear-related research for more than 5 years, spanning magneto-hydrodynamic effects on the corrosion of fusion materials, advanced technology fuels, and for the past three years, he has focussed on the deterioration of spent nuclear fuel (SNF) in aqueous environments. In particular, modelling the radiation emitted from spent nuclear fuel to predict hydrogen gas release and hydrogen peroxide build-up in different waste environments.

He was recently awarded the Roy G. Post Scholarship for work dedicated to nuclear waste management, providing him the opportunity to fly out Phoenix, Arizona to present his work at the Waste Management Symposia 2022. His results are published in multiple highly regarded journals and his mathematical algorithms have been adopted by the National Nuclear Laboratory, UK. The success of his models inspired him to develop his work into an open-source web application, Rad-Dose. A fast easy-to-use tool for any work that requires modelling of radioactive doses received variety of surrounding media from radionuclide containing materials.

Radiation through matter: A geometrical understanding of energy deposition

A new mathematical radiation dosimetry model used to simulate principal geometries has been developed. Using recorded stopping data and either explicitly knowing the radionuclides present in a material or determining averages from a detector, this approach can simulate radiation through any material. This unique approach exposes symmetry in simple geometries to reduce complexity and computation load, which in turn allows for modern programming languages to be utilized and results linked to more computationally demanding models (Finite Element Analysis, Monte Carlo Simulators). The reduced complexity of these models does not suffer from increased inaccuracy to similar more complex simulators (MCNP, GEANT4) allowing one to develop and scale complex models, such as spent nuclear fuel dissolution, with relative ease.

Scotland

Grace Nielson

Grace is a fifth year MGeol student in the School of Earth and Environmental Science at the University of St Andrews. Her MGeol thesis is focused on the Torridonian Diabaig Formation and it’s implications for the origin of life on land. In Spring 2021 she undertook fieldwork on the Isle of Harris investigating the UHT terranes and rare metal pegmatites of the South Harris Complex, which was generously supported by IOM3 and MIS Trust. As a consequence of this project she began working closely with the Mining Institute of Scotland (MIS) to help engage students and graduates about the future of the mining industry. Working with MIS has fuelled her interest in the net zero transition and what that means for natural resources such as critical metals as well as rekindled her enthusiasm for exploration in the High North and Arctic geopolitics which she has loved reading about since she was a kid.

In her free time, Grace enjoys competitive showjumping, painting, and exploring the beautiful Fife Coast.

The future of the arctic: Mineral resources, geopolitics and climate change

The Arctic is commonly thought of as the final frontier when it comes to human exploration and exploitation of Earth’s natural resources. These resources include oil and natural gas, rare-earth metals, and other mineral resources. The vast majority of these deposits are within Arctic state boundaries, however melting sea ice is creating unprecedented access to international waters. The UN states that exploitation of any natural resource beyond the continental shelf of a nation is prohibited, but as more Arctic sea ice melts this is subject to change and major players in the west are making moves to claim these as well as resources on land. Climate change is at the core of access to Arctic resources and it is already effecting the region. This talk will focus on the natural and mineral resources in the Arctic, claims to these resources, and what effect extraction will have on the Arctic region and beyond.

2021 YPLC final - 5 May | Online

2021 YPLC final - 5 May | Online

Winner - North West & North Wales

Mia Maric

2nd place - North East

Frances Livera

3rd place - South West & South Wales

Alastair Houston

Scotland

Catriona Breasley

Midlands

Alex Dickinson-Lomas

South East

Camilla Hurst

Winner - North West & North Wales

Mia Maric

Mia is a third year international PhD student studying Materials Science at the University of Manchester. She completed her undergraduate degree at the University of New South Wales in Sydney Australia, where she won the university medal for the top performing student in Materials Science and Engineering. Mia conducted an internship at the Australian Nuclear Science and Technology organisation, where her passion for nuclear materials and their useability within the nuclear power industry was developed. During her studies, she has been thoroughly involved in an array of outreach activities particularly focusing on equity, diversity and inclusion work. Earlier in 2021, Mia was selected to attend the global young scientist symposium where her passion for encouraging females within science and technology to pursue and excel in research related careers was enhanced.

Outside of research, Mia enjoys playing hockey, running and hiking. When not doing sports, she can be found volunteering at the local cat shelter and trying to bake the perfect chocolate chip cookie.

How do Hexagonal Materials Recrystallise?

Recrystallisation of Hexagonal alloys is extensively utilised within both industrial and research applications as a means of microstructural development and mechanical property refinement. However, the multifaceted nature of this process has meant that the mechanistic drivers for the microstructural as well as textural evolution that occurs during heating is not yet understood. Here, a range of experiments combined with computational modelling techniques have been able to highlight that the deformation imparted onto the alloy prior to recrystallisation strongly dictates its behaviour during heating.

In this study we have developed a model to correlate the deformed microstructure to the strong orientation dependent texture change that is seen in hexagonal alloys during recrystallisation. Therefore, an understanding of the relationship between deformation and recrystallisation is essential if heat assisted texture control is to be utilised as a cost-effective method for mechanical property enhancement of hexagonal alloys.

2nd place - North East

Frances Livera

Frances is a first year PhD student in Materials Science & Engineering at the University of Sheffield and part of the Advanced Metallic Systems Centre for Doctoral Training. She completed her MChem in Chemistry at the University of York in 2019, and took particular interest in Materials Science during her course. Frances completed her final undergraduate year in industry, working full time at Unilever whilst completing her Masters. The Steel City was calling though, and she began her PhD in 2019, sponsored by the Culham Centre for Fusion Energy. Her research aims to improve the complementarity between Additive Manufacturing and Brazing, under the supervision of Prof. Russell Goodall and Prof. Iain Todd. She is involved in undergraduate teaching, will be hosting a Nuffield Research Placement and takes pride in being a STEM Ambassador, helping to inspire the next generation to pursue careers in STEM.

Aside from academic study, Frances can be found exploring and climbing in the Peak District, playing hockey, or baking up a storm. She has had an international upbringing spanning three continents, and enjoys experiencing different cultures and new places.

Improving the Complementarity between Additive Manufacture and Brazing

Additive Manufacture (AM) and brazing have seen significant research interest individually, but their combination has not been widely investigated. AM is a layer-upon-layer building technique that can produce complex, three-dimensional parts in shorter time frames than traditional manufacturing, but is limited by build size for metal part production. Brazing uses a molten filler metal to create a joint between two materials. Combining the geometrical freedom of AM with brazing could produce complex part geometries and reduce lead-times. The disparity between the surface finish of AM and the smoother roughness requirements for a brazed joint is the main challenge in combining the techniques. An AM surface may be tailored by implementing a topographical structure, to aid braze alloy wettability and control flow direction. The applications of this research are considerable due to the freedom of AM and its increasing popularity as a manufacturing technique in aerospace, medicine and the nuclear industry.

3rd place - South West & South Wales

Alastair Houston

Alastair is currently working for Minton Treharne and Davies as a Consultant Materials Scientist, where his role is to perform investigations involving materials identification, mechanical testing, and failure analysis for the marine, cargo, and construction industries.

He studied Natural Sciences at the University of Cambridge, specialising in materials science, during which time he researched laser welding, protective coatings and compositional variations in jet engine turbine blades, and the production of new materials used for low-level nuclear waste storage. He continued his passion for materials science by completing a PhD in the Composites and Coatings Group, University of Cambridge, where his research focussed on the development of novel diesel particulate filters containing fine ceramic fibres. During his PhD, Alastair was heavily involved in the teaching of undergraduate students and spreading the joy of materials science through various outreach events.

In his spare time, Alastair enjoys spending time in the great outdoors, and can often be found hillwalking or cycling, as well as honing his juggling skills.

Finding Success in Failure

Why did it fail? When did it happen? Who is responsible? — Commonly asked questions in the field of materials failure investigations. Materials will degrade from the moment they are put into service, for example through wear of moving components, corrosion in a harsh environment, or fatigue cracking through repeated motions. Recognising this, materials intended for critical applications are carefully selected to withstand their particular service environment. However, sometimes their expected lifetime can be cut short by an unexpected and catastrophic failure, often with a large price tag for damages and litigation.

Once the dust settles following such an incident, it becomes necessary to answer the above questions. Through forensic study of failed materials, an investigator must piece together the evidence to find the nature of the failure. This presentation outlines the process of materials failure investigation with recent case studies on corrosion, fatigue and overload.

Scotland

Catriona Breasley

Catriona is a fifth year MGeol student in the School of Earth and Environmental Science at the University of St Andrews. She is currently researching the formation of hydrothermal manganese deposits at mid ocean ridge spreading centres under the supervision of Dr Eva Stueken and Dr Michael Byrne for her MGeol thesis.

She undertook an exploration geology internship at Cornish Lithium Ltd. in the summer of 2019 which inspired her to continue into further study looking at lithium deposits. This year, Catriona will start a PhD under the supervision of Dr Lee Groat at the University of British Columbia looking at lithium rich pegmatites.

Outside of academia she is an avid hiker, tennis player and loves to collect plant fossils along the beautiful Fife Coastal Path.

Deep-Sea Hydrothermal Manganese Deposition beneath the Arctic Ice Sheet

Deep-sea hydrothermal manganese deposits are known to be significant sources of rare earth elements and other critical metals. Found in a variety of settings, these nodules, crusts and enriched sediments have the potential to be economic sources of metal exploration and extraction.

Gakkel Ridge represents one of the least studied hydrothermal ridge systems in the world. Located beneath the Arctic Ice sheet, exploration and sample analysis is logistically difficult and expensive. Using Ocean Parcels software, a manganese decay and deposition kernel is implemented and sensitivity tested to show areas of enrichment around well studied vent sites across the world. This model is implemented onto Gakkel Ridge where areas of enrichment are located, and likely deposit formations are hypothesised. This talk ultimately aims to explain factors influencing manganese deposit formation, assess the use of advection-based modelling to predict manganese deposit formation and finally discuss these implications for deep sea mining.

Midlands

Alex Dickinson-Lomas

Alex is a PhD student in the School of Metallurgy & Materials at the University of Birmingham. She completed a BSc in Nuclear Science & Materials in 2018 and an MSc in Nuclear Decommissioning & Waste Management in 2019. After an MSc project based in the Cavendish Nuclear radiometric physics team, Alex stayed in the beautiful West Cumbria and started a role as a mechanical engineer for Arup in 2019. This gave brilliant insight into the decommissioning and engineering challenges faced by the aging nuclear sites in the UK and reignited an enthusiasm for understanding materials in a nuclear context. With a hankering for some more fundamental science Alex started a PhD project looking at radiation damage in nuclear materials under the supervision of Dr Yu-Lung Chiu and Professor Martin Freer in August 2020.

Outside of materials science she can often be found clinging to the sides of mountains, swimming in lakes or embarking on sewing projects.

Using Complementary Characterisation Techniques to Understand Radiation Damage in Nuclear Reactor Pressure Vessels

Extending the lifetime of nuclear reactors to improve sustainability is essential for the global future of energy generation. The critical component, the reactor pressure vessel (RPV), is subjected to extreme radiation conditions for over 50 years and must maintain structural integrity to ensure safe and secure reactor operation. Understanding the mechanisms and changes in microstructure and mechanical properties of RPV steels will enable more accurate prediction of lifelong performance. Combining a wide range of complementary characterisation techniques holds the key to understanding how these materials change in harsh environments and how we can create better predictive models for their behaviour.

This talk will briefly explain how combining techniques such as mechanical testing, transmission electron microscopy, atom probe tomography and small angle neutron scattering, is not only useful but necessary to underpin predictions and understand material behaviour.

South East

Camilla Hurst

Camilla is a 3rd year undergraduate reading Materials Science at Corpus Christi College, University of Oxford. Her interest in materials science has stemmed from extracurricular research projects she carried out in high school. These projects have won her prizes internationally, including at the EU Contest for Young Scientist (EUCYS) and the Intel International Science & Engineering Fair (Intel ISEF). She has also been selected to participate in various scientific programs, namely the London International Youth Science Forum and the Weizmann Institute of Science International Summer Science Institute in Israel.

Outside of materials science, Camilla enjoys broadening her knowledge in areas from climate change to female representation in science. She believes in promoting science to the youth, and so has repeatedly volunteered at national young scientist contests. Camilla otherwise likes to spend her time running and painting.

The role of materials and surfaces in the transmission of bacteria

Covid-19 has highlighted the issue of viral transmission not only by particulates, but also via fomite surfaces. This will continue to be a critical issue if we are to prevent other pandemics and problems from antimicrobial resistance. We will see that materials can have an important role in solving this issue.

In my presentation I will discuss which surfaces are problematic in public places by drawing on evidence from a school study. This study shows the types of bacteria that are present as well as the different bacteria survival rates on a variety of materials. Interestingly, the bacterial death rate is highest on some natural woods. This is due to the chemicals involved in the natural defence mechanism of trees. Therefore, we should promote this sustainable material for use on fomite surfaces as much as possible.

2020 YPLC final - 23 September | Online

2020 YPLC final - 23 September | Online

Winner - Midlands

Morgan Lowther

2nd Place - North West & North Wales

Tamás Zagyva

3rd Place - Scotland

Shima Ghanaatian

South West & South Wales

Freddie Russell-Pavier

Alex Starling

North East

Parsons Conference

Minal Patel

South East

Jack Aspinall

Winner - Midlands

Morgan Lowther

Having studied for an MSci in Natural Sciences at the University of Cambridge, UK, Morgan returned to his Midlands roots to work at the Manufacturing Technology Centre in 2016. As part of the National Centre for Additive Manufacturing, he spent time characterising the feedstocks used for metal powder bed printers. This led to a fascination with how powder, printing parameters and post-processing alter the behaviour of additively manufactured materials.

Now a final year PhD student at the University of Birmingham, UK, Morgan's research uses 3D printing to deliver antimicrobials from biomedical implants, hoping to tackle the increasing challenge of implant-associated infections. Engaging with science outreach since his undergraduate days, a highlight has been helping students become human 3D printers. In his spare time, Morgan is a (very) amateur baker, climber and badminton player

Head, shoulders, knees and microbes: 3D printing better implants

Over 100,000 joint replacement surgeries take place each year in the UK alone, accounting for 1 in 10 hospital admissions. But the prevalence of metallic implants belies that the human body is among the most challenging environments for materials design. Implants often fail not through mechanical means, but biologically, by failing to integrate with native tissues and being colonised by microbes. With the increasing prevalence of antimicrobial resistance predicted to kill more people than cancer by 2050, making previously simple surgeries life threatening, preventing implant-associated infection is a necessity.

Conventional approaches have relied on coatings and other secondary processing to modify implants after manufacture. However, in the past decade, advances in metal additive manufacturing (AM) have opened the possibility of radically new approaches to implant design and materials. How might AM simultaneously revolutionise the production of implants and help mitigate the threat of antimicrobial resistance?

This is the last line of the biog text.

2nd Place - North West & North Wales

Tamás Zagyva

Tamás graduated from Eötvös Loránd University, Hungary, with a BSc in Earth Science in 2016 and with an MSc in Materials Science in 2019. His undergraduate research was related to mineralogy and crystallography. During his Master’s studies, he was involved in a research project focusing on bioceramic coatings. Tamás has attended several conferences presenting his undergraduate and Master's research with great success, winning awards in both best poster and best presentation categories. He is the first author of one, and co-author of two, peer-reviewed articles. He started his PhD at The University of Manchester, Dalton Nuclear Institute, UK, in 2019. His PhD topic focuses on the radiation effects on glass-ceramic nuclear waste forms. This research gives an opportunity to continue his committed career path combining geology and materials science.

In his spare time, Tamás enjoys participating on gem and mineral shows, as well as collecting minerals. He is keen on motorsports and enjoys playing board games.

Hip implant materials: novel bioactive coatings for silicon nitride ceramic hip replacements

Total hip replacements are one of the most challenging implants because they need to be created from materials with extremely good mechanical and biological properties. Metals and alloys have been widely used for decades due to their excellent mechanical strength and corrosion resistance. However, the high-wear rate and the toxicity of the chemical components urged the development of non-metallic implant materials like polymers and ceramics. Silicon nitride has recently been introduced as a commercially available bioceramic for total hip replacements with outstanding mechanical properties.

This lecture gives an introduction about the development of total hip replacement materials and presents research about novel bioactive coatings on silicon nitride ceramics, which could speed up the healing process after surgery. An alternative, simple, coating deposition technique has been developed especially for silicon nitride hip implants, where eggshell is the raw material of the coatings.

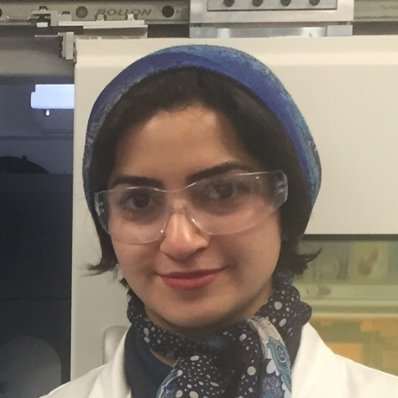

3rd Place - Scotland

Shima Ghanaatian

Shima graduated from the Petroleum University of Technology (PUT) in Iran with a 1st Class Bachelors in Chemical Engineering in 2013. In 2015, she joined Hydrafact Ltd in Edinburgh, UK, where she was mainly involved with corrosion studies in the oil and gas industry. Continuing her passion for addressing global warming challenges and following her win of the prestigious James-Watt Scholarship, she undertook a PhD in Chemical Engineering under the supervision of UK industrial decarbonisation champion, Professor Mercedes Maroto-Valer, at the Research Centre for Carbon Solutions (RCCS). Here, she currently focuses on carbon storage in geological formations. She is heavily involved in the MILEPOST project, where her research study unravelled the CO2 reactive flow drivers at multi-scale (pore to core) during the CO2 sequestration process.

Shima has published numerous peer-reviewed Journal articles and conference papers, and her innovative study of CO2 geological storage monitoring is internationally recognised and has achieved commendation through multiple prizes/awards. She has been awarded the EPSRC Travel Grant, the EXPO&more Workshop Grant and Best PhD Student Presenter Award, the latest at the School of Engineering and Physical Sciences at Heriot-Watt University, UK. Her research studies have been presented at a number of international conferences, most recently the Trondheim CO2 Capture and Storage (TCCS) Conference in Norway in June 2019.

Outside of her project, Shima really enjoys teaching and lab demonstrating for chemical engineering undergraduate students. She wishes to integrate her love for the outdoors with clean atmosphere and sustainable development in her future profession.

Can we securely store CO2 in geological formations to address the global warming challenge

The injection of CO2 in geological formations, e.g. sandstone and carbonate formations, disrupts the equilibrium among the resident phases and causes geochemical changes. Determining safe storage of CO2 in aquifers significantly depends on understanding how fluid phases interact with the porous structure of rocks. Therefore, we investigated the reactivity of CO2-saturated brine with different ionic strengths in contact with sandstone at pressure and temperature conditions representative of storage sites. In this work, we employed a systematic combination of different techniques, including hydrothermal tests, ICP-OES, X-ray diffractometer, Environmental Scanning Electron Microscopy-Energy Dispersive X-ray Spectroscopy (ESEM-EDS), Micro-Computed Tomography (micro-CT) scanning to address the extremely intricate phenomena of flow, transport and reactions occurring over various temporal and spatial scales in sandstone reservoir rocks. The information gained from this study will allow us to build a better understanding of the dominant drivers of CO2 reactive transport in porous media during CO2 storage.

South West & South Wales

Freddie Russell-Pavier

Freddie recently passed his PhD viva and is awaiting graduation from the University of Bristol, UK. In partnership with the National Physical Laboratory, Freddie’s PhD focused on translating the commonly found electro-mechanical components in DVD players and applying them as sensors for high-speed nanoscale imaging within material analysis. Working closely with Dr Oliver Payton and Dr Loren Picco at the University of Bristol, along with collaborators at the National Physical Laboratory, Virginia Commonwealth University (USA) and University College London (UK), Freddie has demonstrated the surprising performant capabilities of the low-cost DVD technology. As a consequence of integrating DVD reading sensors into the technique of high-speed atomic force microscopy, a series of new measurement tools have been created. He has worked on a diverse range of challenges from helping to perfect a novel 2D material manufacturing process, to developing a next generation genome sequencing diagnostic tool that has just completed medical trials for leukemia and breast cancer in the USA.

Nano- to millimetre-scale material characterisation with DVD player components

The digital versatile disc (DVD) player technology, which we might typically use at home to watch movies or transfer files in our workplaces, has been developed into a component capable of nanoscale sensing. DVD player detection systems operate at very high bandwidths and allow for unprecedented sensing speeds when applied to the emerging field of video-rate atomic force microscopy (AFM). This new type of microscope is able to collect topography maps thousands of times faster than conventional AFM, allowing nanoscale processes to be observed in real time under ambient or liquid environments.

The focus detection system in a DVD player read head (also known as an optical pickup unit) is central within a novel video-rate AFM that is able to map out individual strands of labelled DNA molecules in 3D that are less than 1,000,000,000th of a metre in size. Using this technology we are also able to map the locations of carbides, and other inclusions (approximately 2nm high) in thermally sensitised 306 stainless steel, akin to those materials found in nuclear reactor boiler components. Such data gives insight into the local changes in material properties that could lead to critical failure of high-value components in industry.

Alex Starling

North East

Alex graduated from the University of Leeds, UK, in 2018 with a first-class MEng/BEng in Chemical Engineering, specialising in Materials Sciences. Between his 3rd and 4th year of study, Alex gained an industrial placement at Guardian Industries UK, a commercial float glass producer. There, he was involved in developing XRF facilities for analysing and monitoring the quality of raw materials to help predict and maintain a stable glass chemistry. Following that, Alex was offered a project in partnership with Guardian Industries to look into the performance of commercially available self-cleaning glasses. The project involved understanding how the nanostructure of these thin coatings affect the overall performance and functionality of the products. Microscopy techniques such as SEM, TEM, EDX and XPS were used for his research. After completing his research, he was given a full-time role in the process engineering team at Guardian Industries and was awarded for his outstanding achievements by the University of Leeds.

Alex enjoys working with others to create long-lasting, innovative and sustainable solutions to problems. Outside of work, he enjoys mountain biking, DIY projects at home and walking his rescue husky Thor.

Self-cleaning glass, benchmarking and analysis

Self-cleaning glasses work by utilising a thin layer of photocatalytic material, commonly titanium dioxide, to break down organic matter into water-soluble components, which are then washed away by rain. Four methods for producing self-cleaning coatings were analysed in a comparative benchmark. The aim was to understand why certain self-cleaning glasses outperformed others in comparison; whether it be directly related to the surface features or whether it be more influenced by the structure and composition of the nanostructured layers themselves. To understand how the performance of each sample varied, a range of microscopic techniques were used to explore the fundamental macro- and microstructure of each sample and how these govern their overall properties and performance.

Parsons Conference

Minal Patel

Minal graduated from Swansea University, UK, in 2017 with a first-class honour’s degree in Materials Science and Engineering and was awarded the Hugh O’Neil Award for her dissertation research BiVO4 & Cu2O Janus Particles: Towards Solar Energy. Following this, she enrolled as an EngD student at the EPSRC Centre for Doctoral Training in Micro- and Nanomaterials at the University of Surrey, UK, and has just completed her second year on a National Physical Laboratory-sponsored project. Her research work involves investigating failure mechanisms of thermal barrier coatings on gas turbine engines through advanced characterisation techniques under the supervision of Dr Mark Baker, Prof John Watts and Mr Tony Fry. She has already presented at national and international conferences, winning prizes for her presentations.

While working as a doctoral student, she has volunteered as the Treasurer and Secretary of the Surrey Materials Student Forum and is currently the Vice-Chair of the Institution of Engineering and Technology's London Young Professional Network. She regularly takes part in outreach events and mentoring, including being an exhibitor at New Scientist Live and Royal Society Summer Exhibitions. She is also a member of the Mayor's London Scientist scheme, mentoring student-led projects to help them attain the Bronze Crest Award. She has also organised a conference for postgraduate students. Outside of STEM, Minal is multi-lingual and is currently learning Arabic. Her other hobbies include yoga, running, dancing and cooking.

Micro-mechanical testing of aged thermal barrier coatings

There is a continual drive to operate engines and power plants in harsher conditions, such as higher temperatures, with more aggressive fuels, more thermal cycling, etc, to improve efficiency and to underpin the increased use of renewables. The aerospace and energy industries need to be able to develop their materials to perform in these increasingly severe operating environments. The development of coatings for protection against corrosion and oxidation, as well as thermal protection, has facilitated their increased use on turbine components. These high-temperature coatings have complex microstructures that are highly dependent on the manufacturing process, making their lifetime difficult to predict and therefore reducing reliability in their application and maintainability. During the service of a thermal barrier coating (TBCs), a thermally grown oxide (TGO) layer develops between the bond coat and the top coat. Typically, failure and cracking occur close to this TGO layer. It is useful to examine these cracks using conventional microscopy techniques, however, this does not provide a fully representative understanding of the crack morphology and path in the sample.

Focused ion beam (FIB) tomography can be used to characterise the crack properties in three dimensions. Furthermore, micromechanical testing, such as hot nano-indentation, micro-pillar compression tests and micro-cantilever tests, can be performed to understand how the degradation in the localised mechanical properties and changes in chemistry near and through the crack govern its path.

South East

Jack Aspinall

Jack graduated from the University of Oxford, UK, in 2019 with a MEng in Materials Science. His final undergraduate year was spent under Professor Jason Smith investigating nanodiamond-based photonics, leading to a publication in Optical Materials Express. Jack is now pursuing a DPhil in the Oxford Department of Materials, under Professor Mauro Pasta, funded by The Faraday Institution and UK Research and Innovation into next-generation lithium batteries. The project focuses on investigating lithium metal anodes to replace the incumbent graphite anodes. Alongside his research, Jack enjoys endurance sport. He’s ran two marathons and multiple half-marathons and is currently training for an Ironman triathlon.

The advent of the electric car

Road transport accounts for a fifth of the UK's CO2 emissions and contributes significantly to air pollution. The switch from internal combustion to electric cars is therefore crucial to reduce our environmental impact.

Tesla, a company only founded in 2003, has revolutionised the global outlook on electric cars. It used to be widely agreed that the range, performance and cost were all intrinsically far worse than combustion engine cars. Today, this is not the case. Cost and range are progressing toward that of traditional cars, and both their performance and efficiency are greater. This change is reflected in UK legislation that requires all new cars sold from 2035 to be electric vehicles. The rapid speed of change sparks many questions: How have electric cars achieved this success? Why are electric cars all so powerful? What’s inside an electric car? What technical progress do we need to hit the 2035 goal?

2019 YPLC final - 1 May | The Armourers' Hall, London

2019 YPLC final - 1 May | The Armourers' Hall, London

Winner - South East

Megan McGregor

2nd place - South West & South Wales

James Grant

3rd place - North West & North Wales

Jack Saunders

Midlands

Matthew Wadge

North East

Federica Rosaria Lisa

Scotland

Abigail Georgia Robinson

Winner - South East

Megan McGregor

Megan graduated from the University of Cambridge in 2015 with a first-class MSci in Natural Sciences, specialising in Materials Science for her final two years. With pilots in the family, aviation has always been of particular interest to Megan; this interest led her to embark on a PhD funded by EPSRC and Rolls-Royce plc investigating new alloys for commercial gas turbine engines. Her project looks specifically at a novel coating material required to attach abrasives onto the end of rotating turbine blades, in the pursuit of a more efficient shroudless sealing system.

Alongside her research, Megan recently completed an RCUK policy internship at the Government Office for Science, working on the Innovation and Industrial Strategy team as part of the Sustainable Economy Division. She enjoys being involved in her group's outreach activities, and has delivered a number of well-attended talks at the Cambridge Science Festival and at the inaugural Cambridge Soapbox Science event. In her spare time, Megan enjoys reviewing popular science books for Chemistry World, and studying Japanese - she is excited to visit Japan and present her research at the Beyond Nickel-Based Superalloys later this year.

World's hottest superglue: Materials requirements for better sealing in jet engines

Jet engines function using a high-temperature gas stream to do work and generate thrust. In the aviation industry, where fractional increases in efficiency equate to savings of hundreds of thousands of pounds, preventing loss of gas from this stream is crucially important. This requires sealing between the moving turbine blades and the stationary casing of the turbine. Any sealing solution must not only increase sealing efficiency, but must stand up to the ever-increasing temperatures and rotational speeds of turbines, whilst remaining light.

Such niche applications provide opportunities for new intermetallic materials, specially tailored to withstand this challenging environment. This talk will explain current and new sealing systems in the high-pressure turbines of jet engines, and explore the materials requirements for such new systems.

2nd place - South West & South Wales

James Grant