Introduction to Corrosion & Its Prevention

Focussing on the fundamentals of corrosion and how it can be prevented

A suite of courses highlighting practical aspects important in metallurgy

It would be difficult to identify anything that we use that either isn't made from metal or hasn't involved metal somewhere in its manufacture. Metals play a crucial role in everything we do and it is important to understand their structure and properties and how these relate to processing in order to choose the right one and predict how it will operate in service.

Our suite of nine courses highlight key aspects of the application of metals. The courses are delivered in an accessible and engaging way and are very much focussed on practical side of things.

Earn the IOM3 Certificate in Metallurgy in Practice by completing three of the nine courses in the suite within 12 months or earn the IOM3 Diploma in Metallurgy in Practice by completing six of the nine courses in 12 months. Book all of your courses at once to receive a discount on the course fees.

There are nine courses in the Metallurgy in Practice suite and all are delivered virtually using Zoom.

Complete three courses in 12 months and receive the IOM3 Certificate in Metallurgy in Practice.

Complete six courses in 12 months and receive the IOM3 Diploma in Metallurgy in Practice.

The fee to attend three courses leading to the IOM3 Certificate in Metallurgy in Practice is £1620 + VAT at 20% where applicable. This represents a 5% discount compared to booking three courses separately.

The fee to attend six courses leading to the IOM3 Diploma in Metallurgy in Practice is £3078 + VAT at 20% where applicable. This represents a 10% discount compared to booking six courses separately.

IOM3 members and subscribers to our Business Partner Programme are entitled to an additional discount of 10% on the course fees.

Special rates for Student, Apprentice and Early Career members of IOM3 of £255+VAT and £450+VAT for three and six courses respectively are availble.

Clayton studied metallurgy at Imperial College and gained a PhD from the University of Sheffield looking at offshore corrosion fatigue. After working for British Steel Technical as a metallurgical investigator and then corrosion test laboratory manager, he joined Cameron (now called One Subsea) in 1990. He eventually became senior metallurgist and worked on major topside and offshore projects for operators such as BP, Shell, AGIP, Total, and Conoco. He also had responsibility for the material selection and corrosion prevention for topside and subsea projects and for the metallurgy and welding of equipment including wellheads, BOPs, flowlines, choke valves, risers, manifolds, Christmas trees and associated items.

Since 2000 Clayton has been director of Lloyd-Thomas Consultancy Ltd, providing metallurgical support and training. He has continued to work in oil and gas as well as other engineering sectors, such as power engineering, aerospace and biomedical, has carried out numerous failures investigations and has acted as an expert witness in litigation cases.

He has run over 250 metallurgy courses on various aspects of metallurgy and has been working with IOM3 since 2020.

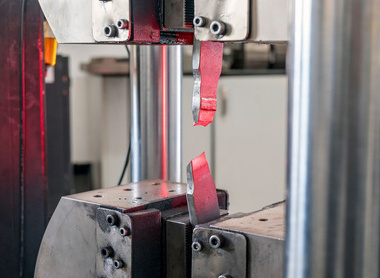

Focussing on the fundamentals of corrosion and how it can be prevented

A one-day course exploring the basic concepts of metallurgy

One-day course focussing on the manufacture, fabrication and metallurgy of steels and cast irons

One-day course exploring factors affecting failure modes and an introduction to failure analysis.

One-day course exploring what to look for and how to evaluate deviations from a material specification

An introduction to the principles of materials selection for engineering applications.

An introduction to the principles of testing and its importance

Find out more

One-day course exploring the metallurgy and application of stainless steels